Working method of take-up winding device capable of automatically cleaning cable

A technology of winding device and working method, which is applied in the field of cables, can solve problems such as cable damage, power failure, and cable winding difficulties, and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

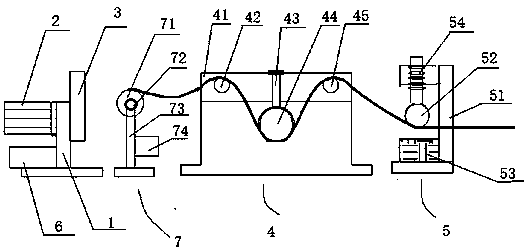

[0016] like figure 1 The working method of a cable self-cleaning closing winding device shown, the cable self-cleaning closing winding device includes a frame 1, a driving motor 2, a winding wheel 3, a tensioning device 4 and a cleaning device 5, and the winding The wheel 3 is fixed on the inside of the frame 1 by a roller, the driving motor 2 is arranged on the left side of the frame 1, and its drive shaft is connected to the roller, and the tensioning device 4 is arranged between the winding wheel 3 and the cleaning device 5 Described cleaning device 5 comprises support 51, cleaning hair brush wheel 52, cleaning sponge 53, and described cleaning sponge 53 is fixed on the below of support 51, and cleaning hair brush wheel 52 is arranged on the top of cleaning sponge 53, and described cleaning hair brush The wheel 52 is provided with a height adjustment wheel lever 54 . The height adjusting wheel bar 54 is movably linked with the upper part of the bracket 51 , and the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com