Conveying equipment special for lignite high-temperature pyrolysis semi-coke, conveying method and application

A technology of high-temperature pyrolysis and conveying equipment, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., to achieve the effects of promoting rotation, good sealing, and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

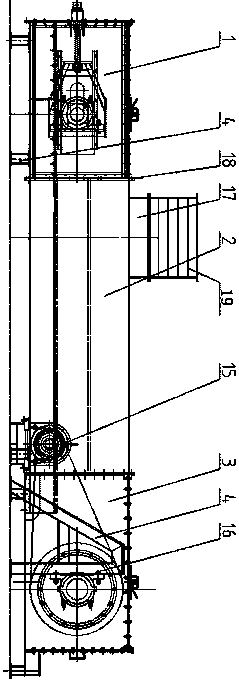

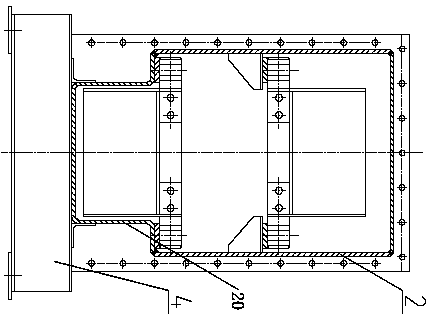

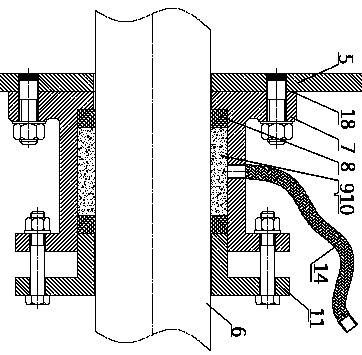

[0040] like figure 1 As shown in the figure, a special conveying equipment for lignite high-temperature pyrolysis semi-coke includes a box-sealed tail 1, a middle section 2, an air-tight head 3, outriggers 4, a scraper chain, a driving device 15, and an independent external bearing. The seat support 16, the feeding port 17.

[0041] Since the temperature of high temperature pyrolysis of lignite is as high as about 600 °C to about 900 °C, the temperature of semi-coke after pyrolysis is generally 800 °C, and the highest is 850 °C. Considering the high temperature expansion coefficient and high temperature mechanical strength of the selected material and the high temperature weld strength after welding between different materials.

[0042] like Figures 1 to 2 As shown, in order to solve the high temperature expansion problem of the buried scraper conveyor, a high temperature resistant expansion joint 19 is firstly arranged between the pyrolysis furnace and the conveyor, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com