Shielding paper processing method

A processing method and a common technology, applied in chemical instruments and methods, paper/cardboard layered products, preventing/reducing unwanted electric/magnetic effects, etc., can solve poor shielding effect, easy acid corrosion of insulating paper, use Short service life and other problems to achieve the effect of prolonging service life and avoiding acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

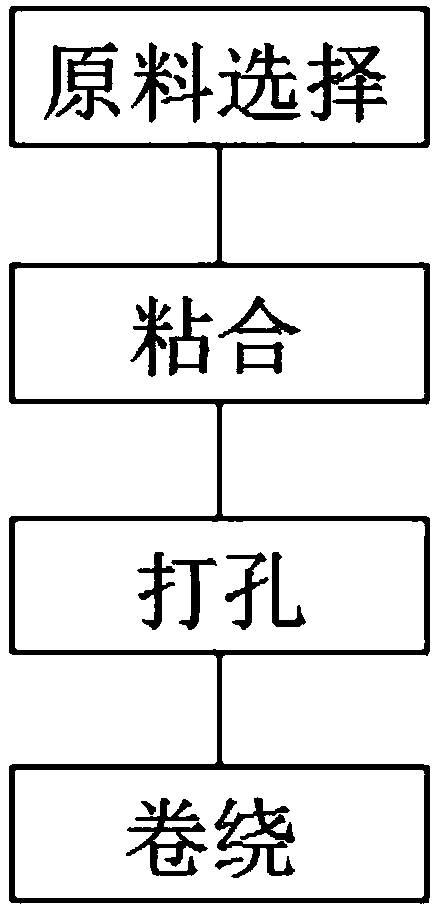

[0019] see figure 1 , this specific embodiment discloses a processing method of shielding paper, and the shielding paper is prepared through the following steps:

[0020] Raw material selection: choose aluminum foil paper and high-voltage cable paper; feasible, in this specific embodiment, the thickness of the high-voltage cable paper is 0.08 mm, and the number of turns in the winding step is 30 layers. In other specific embodiments of the present invention, other thicknesses can also be used, which are determined according to specific processing requirements.

[0021] Bonding: bonding the aluminum f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com