A Universal Compliance Mechanism

A universal and elastic body technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of easy wear of steel plates, many structural restrictions, and reduction of reset torque, and achieve the effect of high precision and high reliability of the return center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

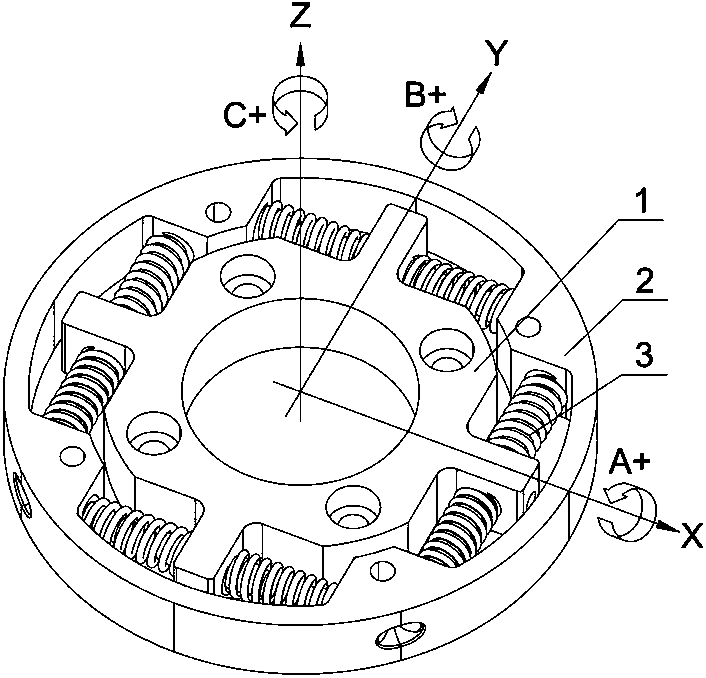

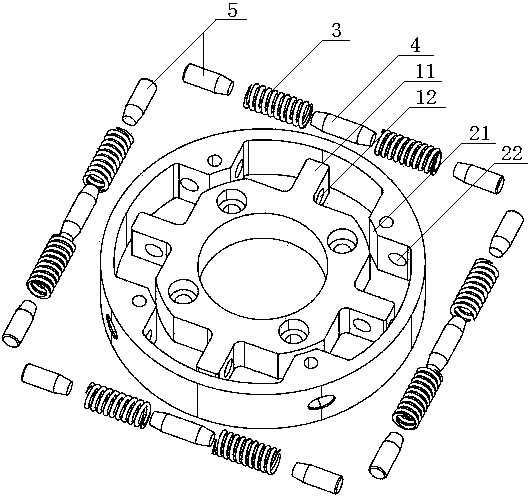

[0019] like figure 1 As shown, a universal compliance mechanism includes an inner ring body 1, an outer ring body 2 and an elastic body 3, the inner ring body 1 is arranged in the outer ring body 2, and the elastic body 3 is arranged in the inner ring body 1 and the elastic body 3. Between the outer ring bodies 2, the elastic deformation of the elastic body 3 is used as the recovery tension between the inner ring body 1 and the outer ring body 2 for relative translation, rotation and inversion, and between the inner ring body 1 and the outer ring body 2 There is a gap between them, and the gap at least ensures that the relative translation, rotation and flipping strokes between the inner ring body 1 and the outer ring body 2 do not interfere within the elastic deformation range of the elastic body 3. In this embodiment, the space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com