A processing method and processing system for a precision worm gear pair

A processing method and technology for worm gear pairs, which are applied in the directions of worm gears, metal processing equipment, gear teeth, etc., can solve the problems that the machining accuracy of worm gear pairs cannot be guaranteed, and the accuracy of worm gear pairs cannot be improved, so as to avoid insufficient error offset and avoid cutting. In place, to ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

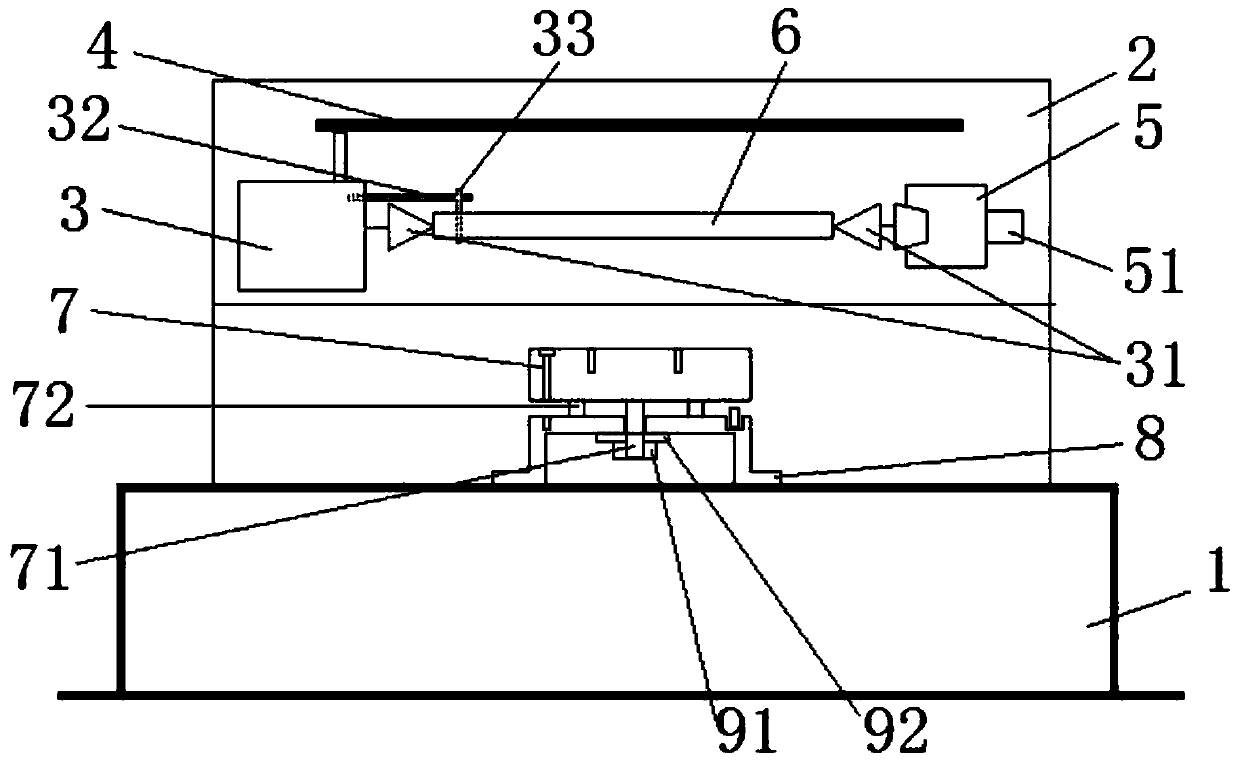

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

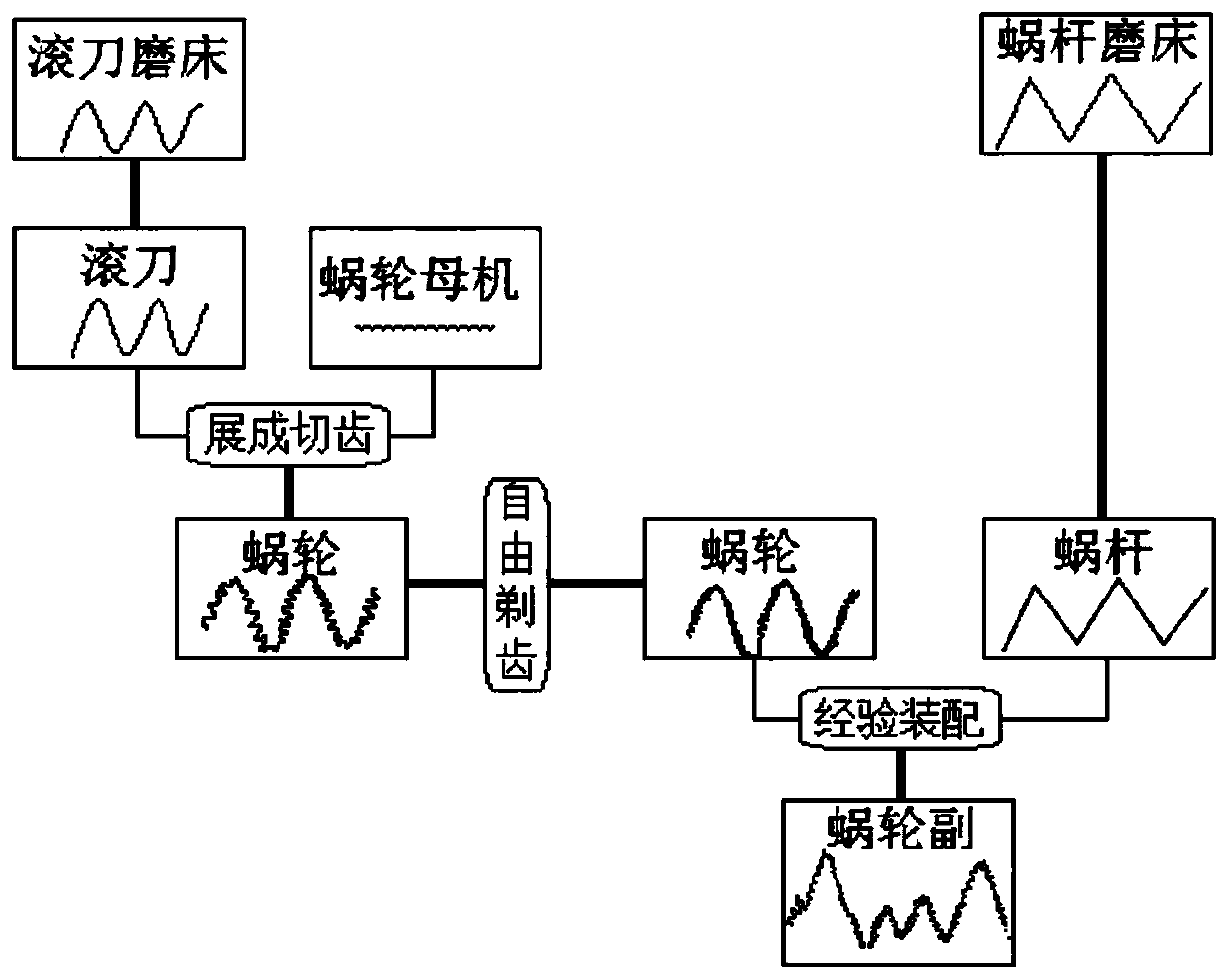

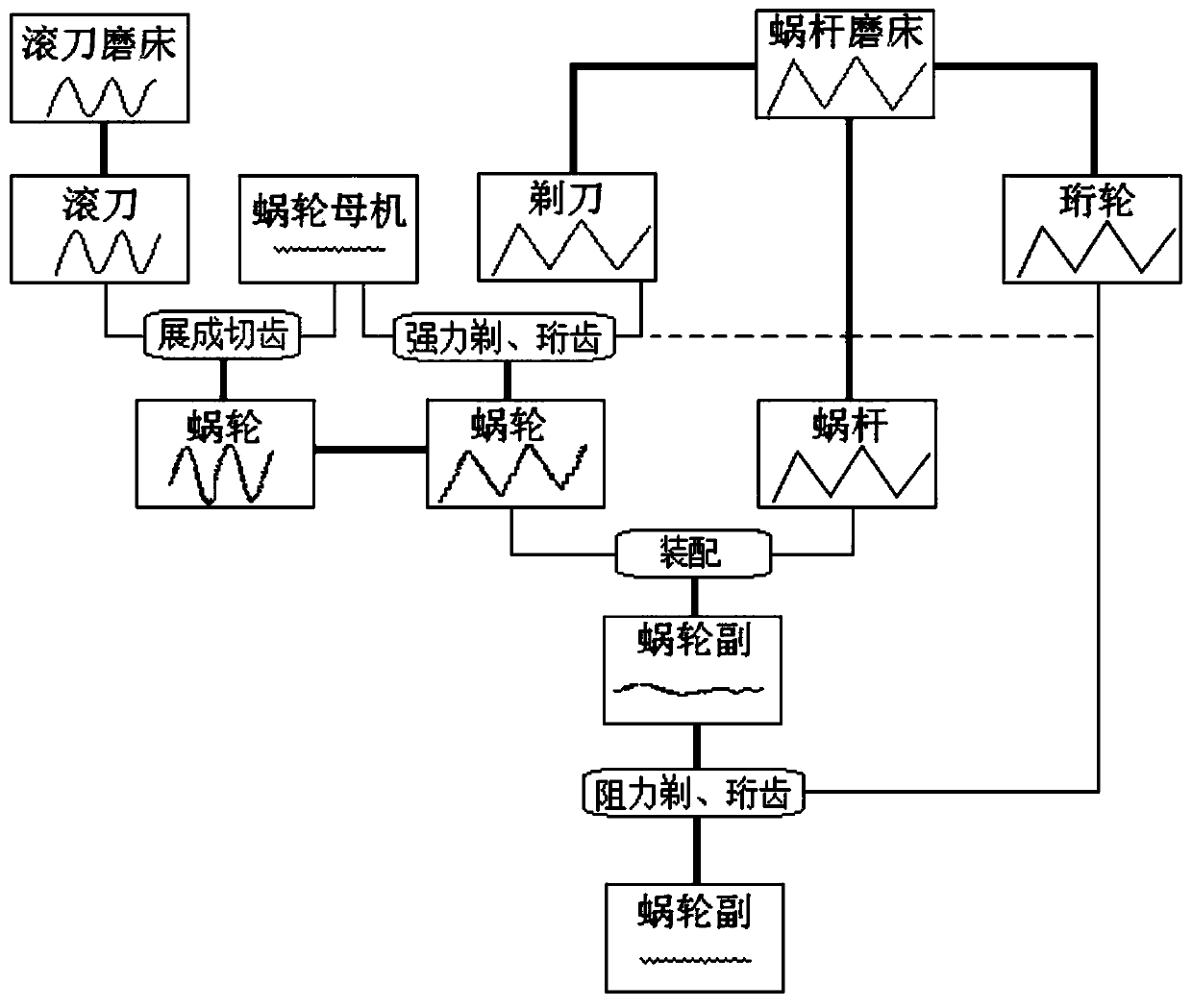

[0034] see figure 2 , a kind of worm gear pair processing method, it comprises the steps:

[0035] Step 1: Prepare the worm, input the process parameters of the worm to be processed to the numerical control system of the numerical control worm grinding machine, start the numerical control worm grinding machine, and make the worm, whose error curve rule "inherited" the error curve rule of the worm grinder;

[0036] Step 2: gear hobbing, install the hob on the high-precision worm gear master machine, hob the gear blank, and make a rough-machined worm gear, whose error curve law "inherited" the error curve law of the hob;

[0037] Step 3, power shaving or honing, grind the razor or honing wheel with the worm grinder in step 1, the error curve law of the razor or honing wheel will "inherit" the error curve law of the worm grinder; then remove the step For the hob on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com