Mineral separation method for improving high-sulfur magnetite and hematite mixed ore separation indexes

A beneficiation method and iron ore technology are applied in the beneficiation of high-sulfur magnetic-hematite mixed iron ore, and the field of beneficiation indicators of high-sulfur magnetic-hematite mixed iron ore, which can solve the problems of high beneficiation cost, low recovery rate, high The complex process of beneficiation and other problems can achieve the effect of simple and easy operation and stable operation in production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

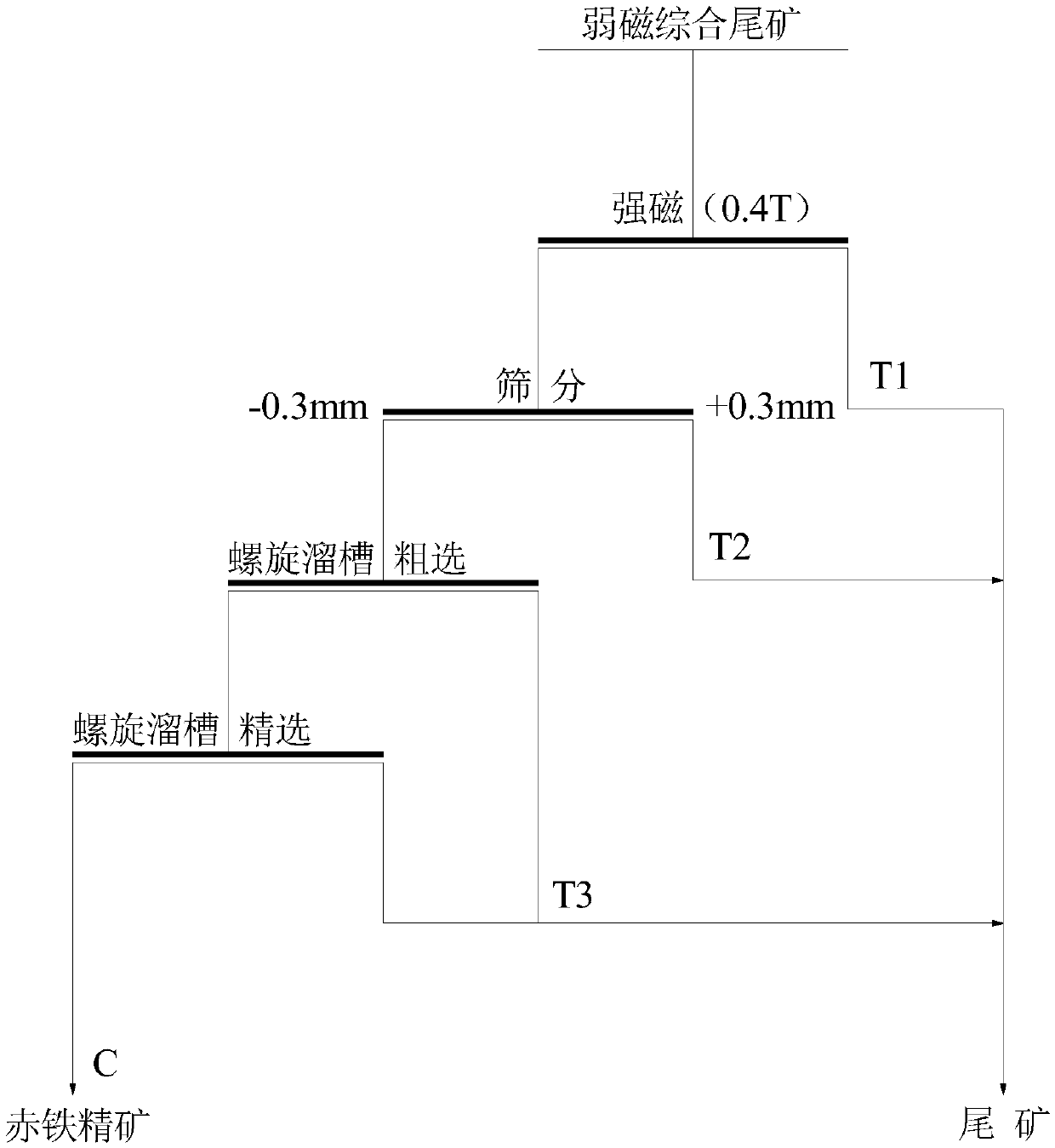

[0021] In order to describe the present invention, a beneficiation method for improving the beneficiation index of high-sulfur magnetic-red mixed iron ore of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0022] The high-sulfur magnetic-red mixed iron ore and weak magnetic comprehensive tailings were taken from an iron ore processing plant in Anhui. The chemical multi-element analysis results of the raw ore and weak magnetic comprehensive tailings are shown in Table 1 and Table 2 respectively; The results of iron phase analysis of tailings are shown in Table 3 and Table 4.

[0023] Table 1 raw ore chemical multi-element analysis results (%)

[0024] Laboratory items

TF

SiO 2

Al 2 o 3

CaO

MgO

content(%)

38.50

15.01

3.82

8.90

1.78

Laboratory items

S

P

K 2 o

Na 2 o

/

content(%)

5.94

0.81

0.78

0.59

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com