Multifunctional automatic environment-friendly welding cap

A multi-functional and automatic technology, applied in ophthalmic surgery, eye masks, etc., can solve problems such as human injury, and achieve the effects of low cost, wide application range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

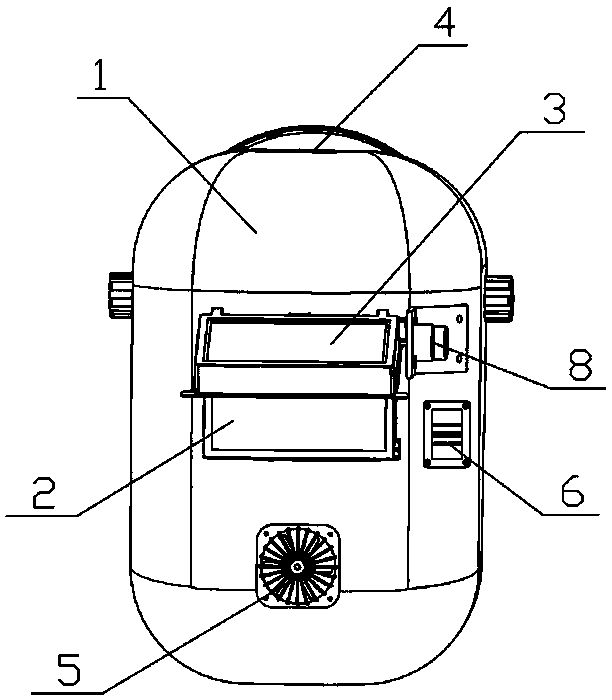

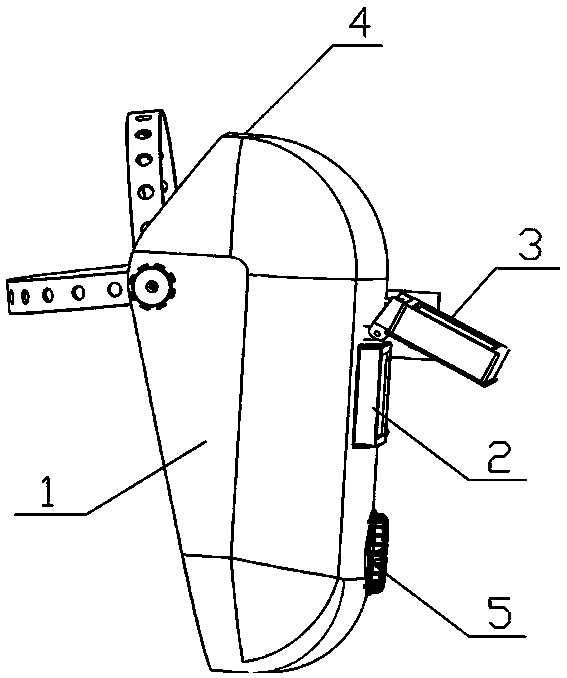

[0022] like figure 1 , 2 As shown, the multifunctional automatic environment-friendly welding helmet of the present invention includes a face shield 1, an inner eyepiece 2 is inlaid on the face shield 1, and an outer eyepiece 3 of a removable structure is provided on the outer side of the inner eyepiece 2. In this embodiment, the outer eyepiece 3 is connected to the mask 1 through a rotating shaft, and the right end of the rotating shaft is connected to the outer eyepiece driving motor 8 through a gear set that meshes with each other, so that the outer eyepiece 3 can be turned up and down along the rotating shaft. Or, the outer eyepiece 3 adopts a translational structure, the left end is slidingly connected with the mask 1, and the right end is provided with a rack belt, which is meshed with a gear fixedly connected to the outer eyepiece drive motor 8 motor shaft. During welding, the darker outer eyepiece 3 is located outside the inner eyepiece 2 to protect the eyes; when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com