Test tool of direct-current-centrifugal two-component nozzles

A two-component, nozzle technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as difficult pressure drop measurement, difficult to meet sealing requirements, high material costs, etc., to reduce construction cost, improve sealing isolation, and ensure the effect of structural consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

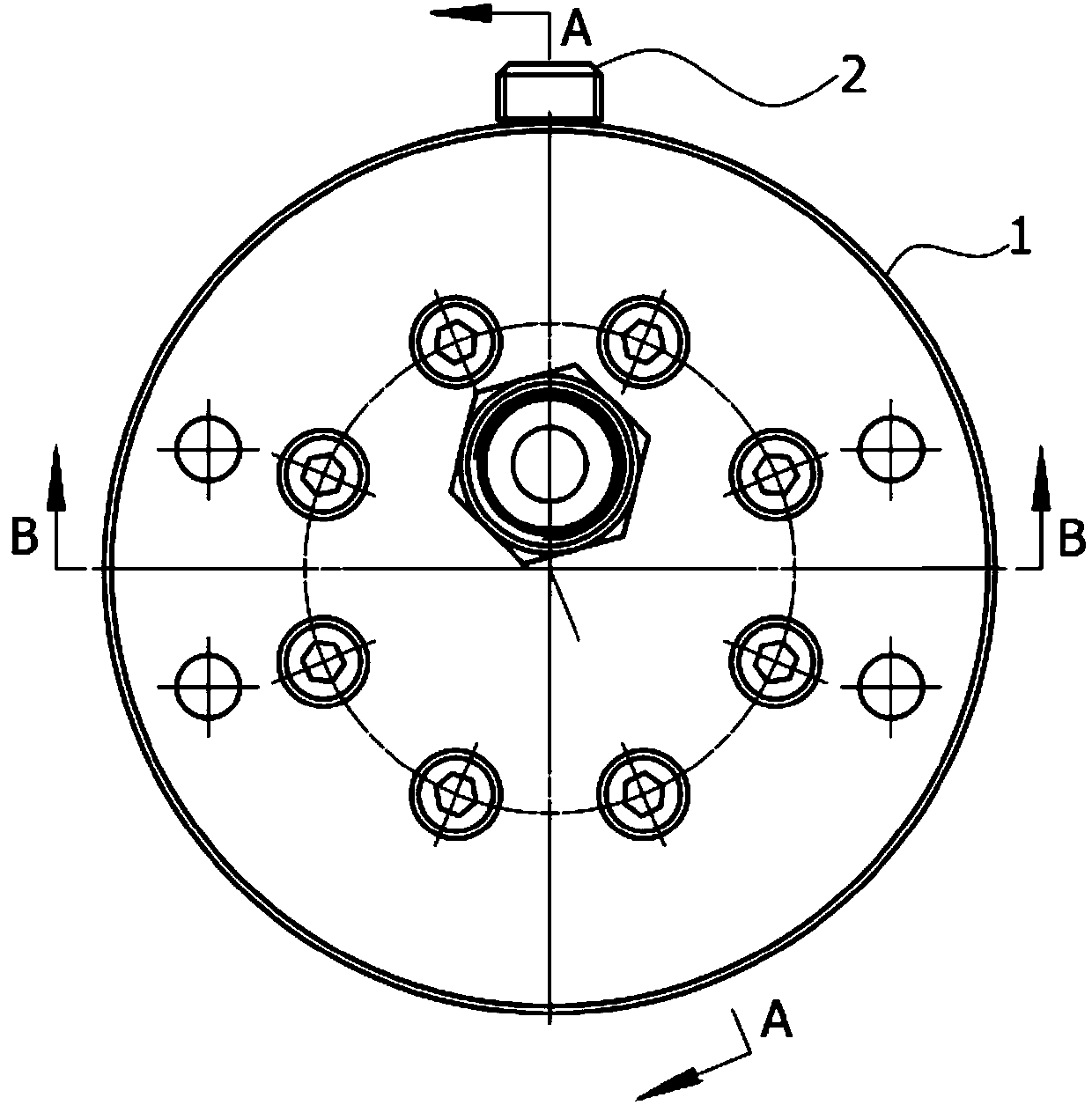

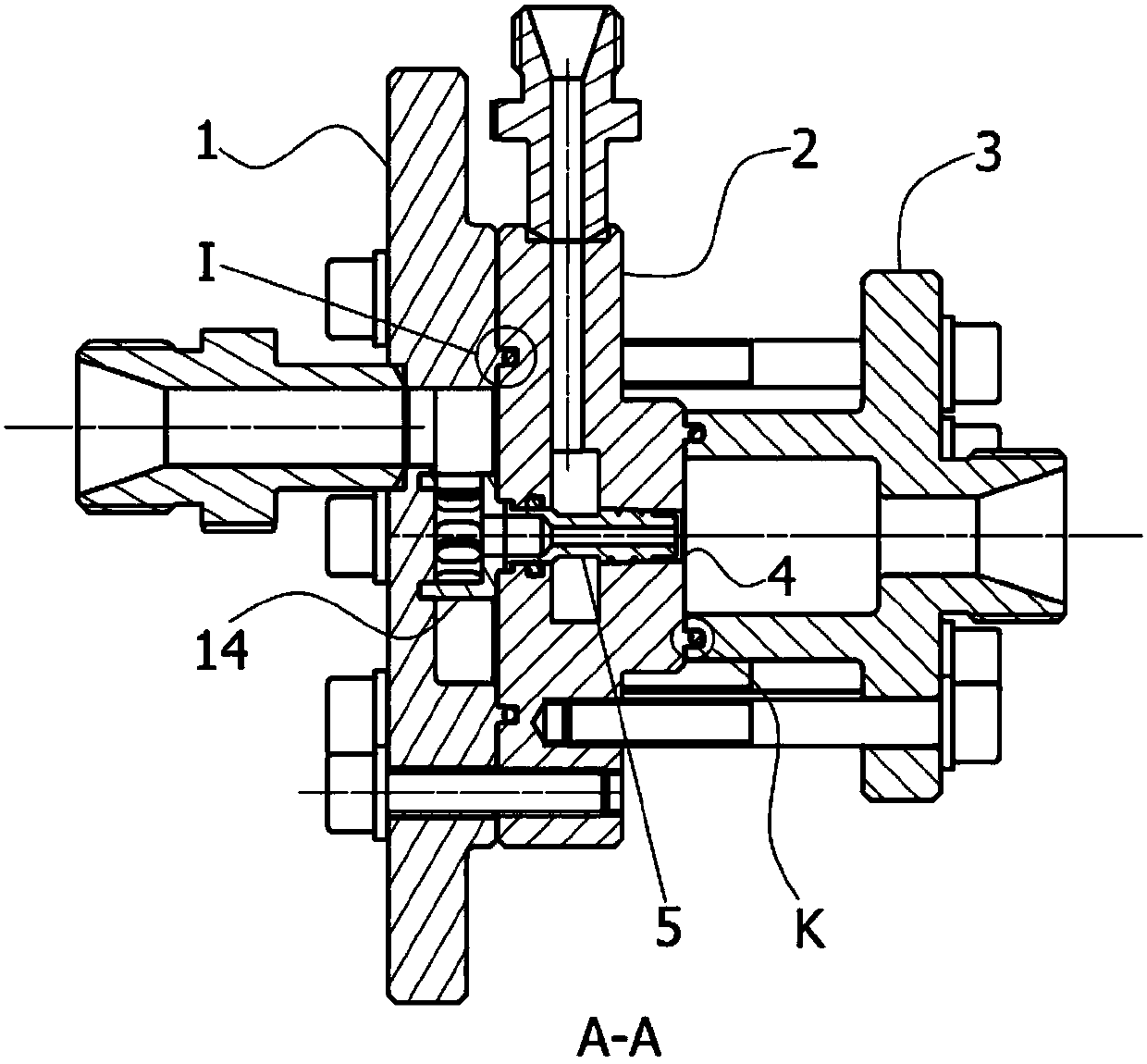

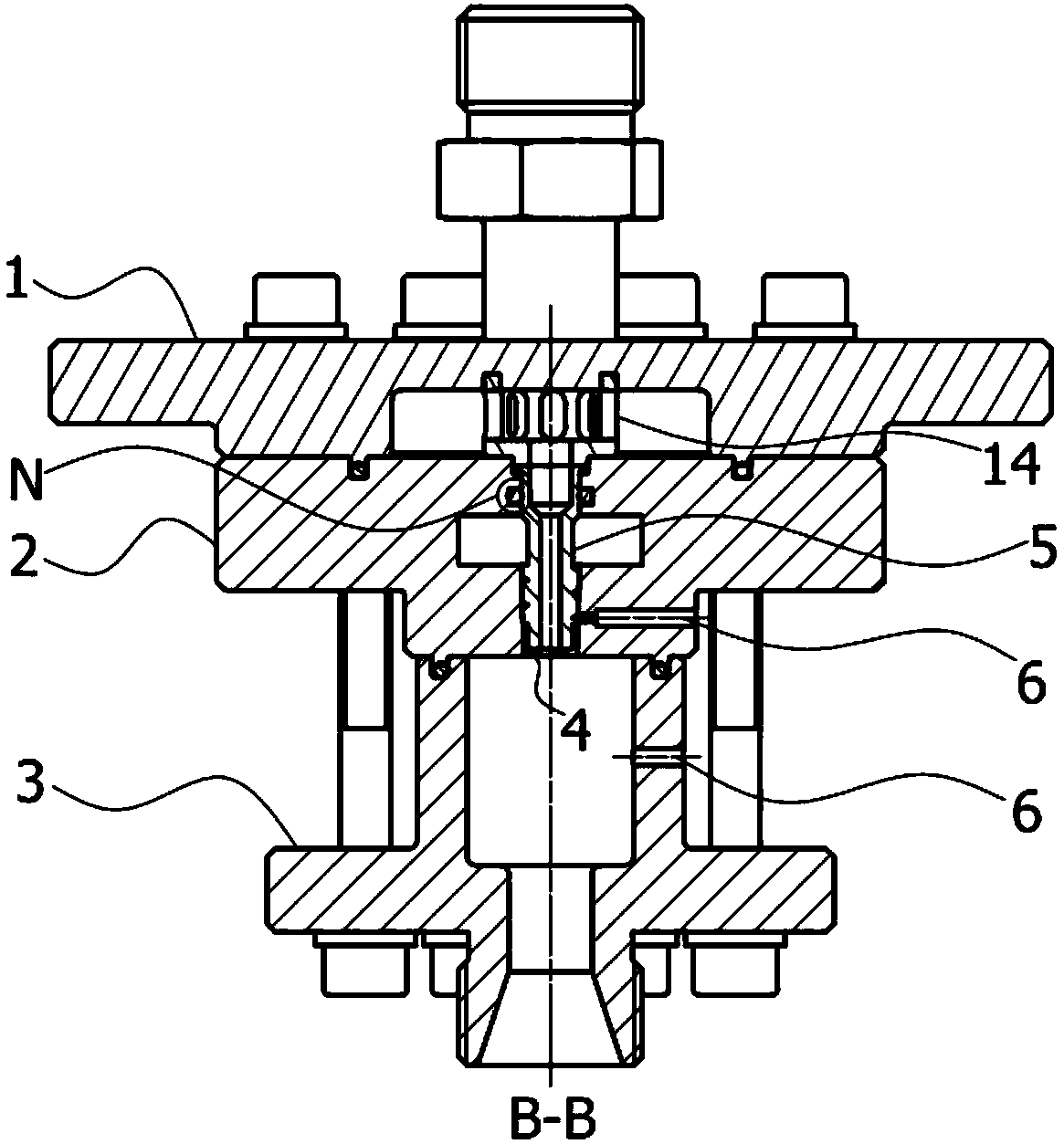

[0048] This embodiment provides a test tooling for a direct-flow-centrifugal two-component nozzle 5, wherein: figure 1 The front view of the test fixture of the direct current-centrifugal bicomponent nozzle 5 provided for the embodiment of the present invention; figure 2 for figure 1 Middle A-A direction view; image 3 for figure 1 Middle B-B direction view. Such as Figure 1~3 As shown, the test tooling of the direct-flow-centrifugal bicomponent nozzle 5 includes a gas oxidant chamber 1 , a liquid fuel collection chamber 2 and a back pressure chamber 3 from left to right. Specifically, the gas oxidant chamber 1, the liquid fuel liquid collection chamber 2 and the back pressure chamber 3 are detachably connected in sequence. Wherein, the liquid fuel liquid collection chamber 2 is provided with a conical through hole 4 extending left and right, the conical through hole 4 communicates with the liquid fuel liquid collection chamber 2 and the back pressure chamber 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com