Organic cotton and wool blended knitted fabric and making method thereof

A technology of knitted fabrics and organic cotton, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of poor anti-wrinkle performance, high price, and difficult washing, so as to enhance anti-pilling performance and ensure yarn quality , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Specific process flow:

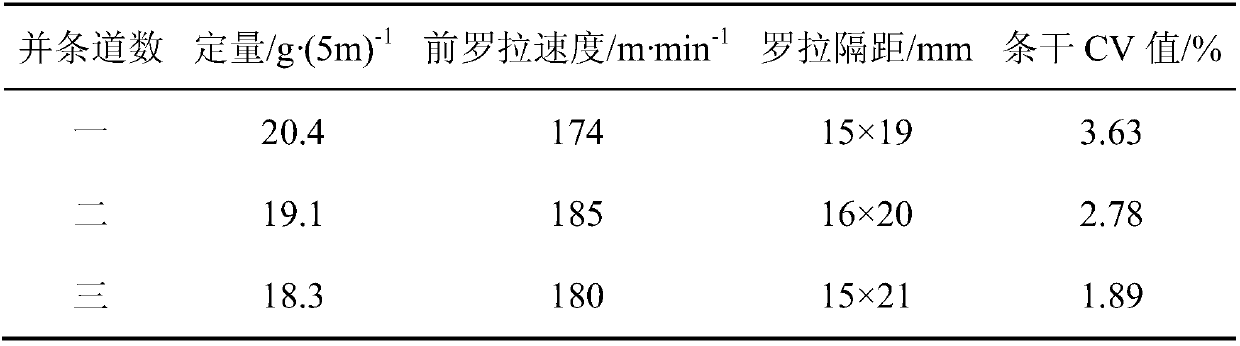

[0038] Spinning process: pretreatment → wool blending → carding → drawing frame → roving → spinning → winding;

[0039] Weaving process: organic cotton fiber / wool fiber blended yarn → doubling → rewinding → weaving piece → sleeve → flat car → hand sewing → washing → drying → ironing → packaging → storage.

[0040] (1) Selection of yarn raw materials

[0041] According to the characteristics of organic cotton and wool fiber, select organic cotton and wool fiber raw materials, such as fiber length, uniformity and other indicators. The organic cotton and wool blending ratios of different blending ratios are optimized to meet the requirements of fabric yarns and clothing.

[0042] High-quality organic cotton fibers are selected as raw materials. High-quality organic cotton fibers have good overall length and low short-lint rate. The length of the main fiber is about 31mm. When spinning, the fabric can be smooth, soft and not easy to pilling. Wool f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com