A long-acting anti-rust and anti-rust agent for metal surfaces

A technology of metal surface and rust transfer agent, applied in the field of anti-corrosion materials, can solve the problems of general microbial corrosion protection effect, high toxicity of rust and rust transfer agent, poor construction economy, etc. The effect of strong rust ability and low level requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

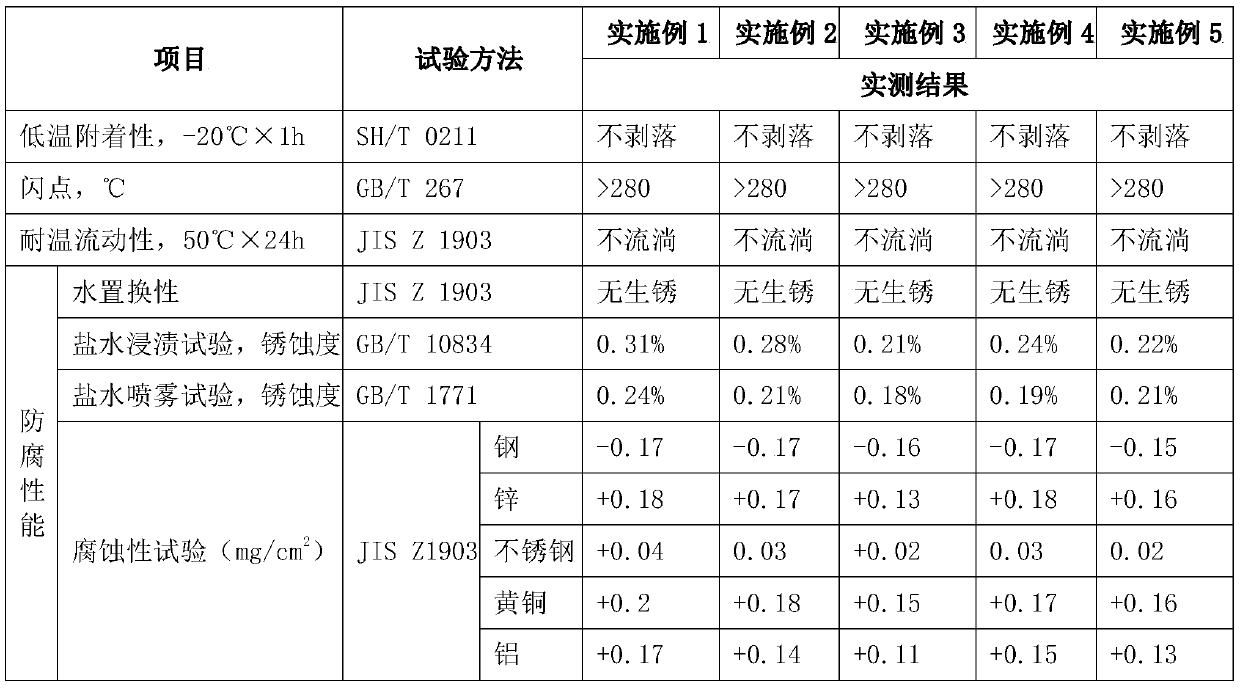

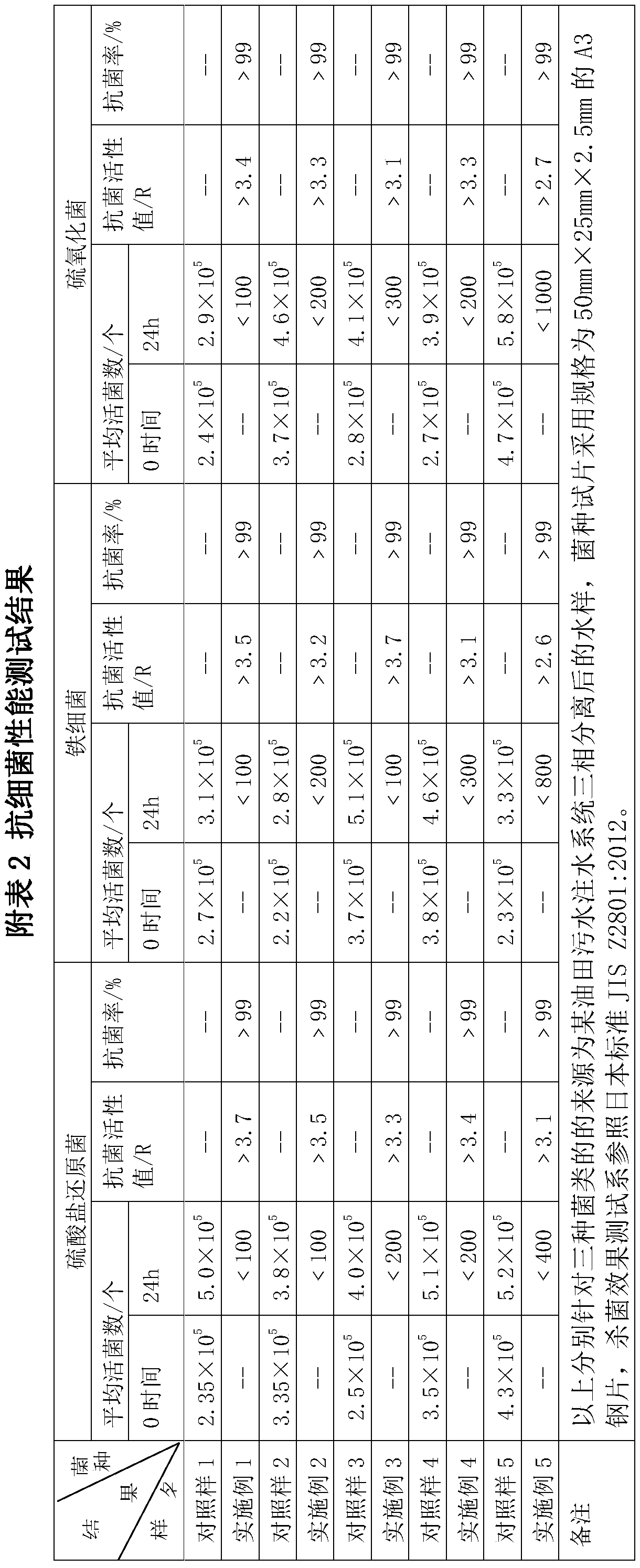

Embodiment 1

[0023] A long-acting anti-rust and anti-rust agent for metal surfaces, the composition of which is 30% by weight of carrier oil, 4% of penetration stabilizer, 10% of slow-release carrier, 2% of antioxidant, and sterilizer 3%, thixotropic agent 2%, phytic acid 20%, gallic acid 9%, polyaniline 20%.

Embodiment 2

[0025] A long-acting anti-rust and anti-rust agent for metal surfaces, its composition weight by percentage is 34.5% of carrier oil, 3.2% of penetration stabilizer, 9% of slow-release carrier, 1.8% of antioxidant, and sterilizer 3.5%, thixotropic agent 3%, phytic acid 17.5%, gallic acid 10.5%, polyaniline 17%.

Embodiment 3

[0027] A long-acting anti-rust and anti-rust agent for metal surfaces, the composition of which is 40% by weight of carrier oil, 8% of slow-release carrier, 1.5% of antioxidant, 4% of sterilizer, and thixotropic agent 4%, osmotic stabilizer 2.5%, phytic acid 15%, gallic acid 12%, polyaniline 13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com