Five-coproduction process for comprehensively utilizing biological straw

A technology of bio-stalk and pentagonal production, applied in the direction of bio-fuel, waste fuel, petroleum industry, etc., can solve the problems of poor economic benefits, low technical level, and small number of large-scale cattle and sheep farms, and achieve the improvement of straw utilization scale, Conducive to economic development and environmental improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: A brief description of the pentagonal production process of comprehensive utilization of biological straw:

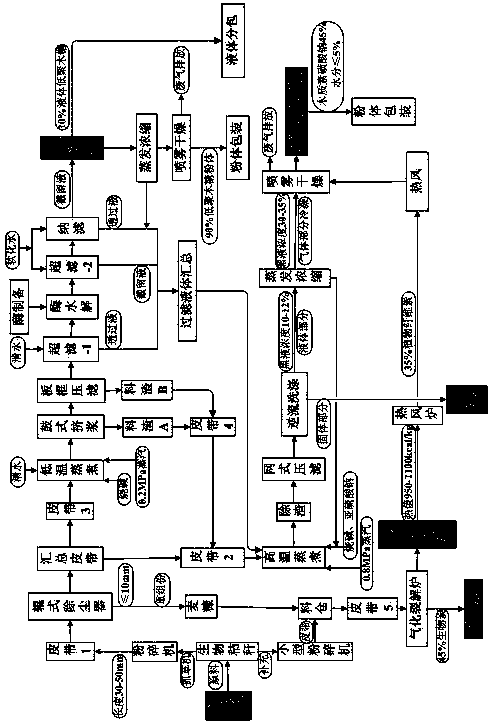

[0042] The raw materials for the realization of the penta-generation process technology are all biological straws, such as figure 1 As shown, it consists of three main process routes, and the materials of the three main process routes are mutually utilized to finally achieve the purpose of comprehensive utilization.

[0043] Process route 1:

[0044] The first route is the production of xylooligosaccharides. The biological straw is crushed and screened, and the fiber length is 30-50mm. The crushed straw enters the belt 1 and is aggregated after passing through the roller dust collector. Adding alkali and water, controlling the concentration of alkali solution, liquid ratio and time, and passing steam at 90-95°C During cooking, the percentage of caustic soda is controlled at 7%, the liquid ratio is controlled at 6.5-7:1, the time is controlled at 6...

Embodiment 2

[0055] Example 2: Environmental Benefit Analysis of Penta-generation Process of Comprehensive Utilization of Biological Straw

[0056] Wastewater from the production of xylooligosaccharides in the first main process line (the permeate of ultrafiltration-1, the retentate of ultrafiltration-2, and the permeate of nanofiltration) returns to the second route to prepare lye. It is the core indicator for the comprehensive utilization of waste water in the whole five cogeneration process without discharge.

[0057] The solid waste is returned to the second route as a raw material to continue cooking, and the utilization of the solid waste does not affect the implementation of this route.

[0058] The exhaust gas produced in the spray drying section of xylooligosaccharides meets the emission standards through the combination of cyclone dust removal and bag dust removal.

[0059] According to the process calculation, taking wheat straw as an example, the second process route uses 100,...

Embodiment 3

[0066] Example 3: Economic benefit analysis of the penta-generation process of comprehensive utilization of biological straw

[0067] The third process route uses the chaff residue (ash, wheat bran, crude protein, etc.) produced during the crushing and screening process of the first and second process routes to crack and gasify. The chaff residue accounts for about 10% of the total biological straw, about 10,000 tons per year (Annual utilization of biological straw is 100,000 tons), and the production of cracked gas is 1.6×10 7 Standard cubic, calorific value 1.52×10 9 Kcal, equivalent to 1.9 million cubic meters of natural gas, is worth 4.75 million yuan at 2.5 yuan per cubic meter; about 2,500 tons of biochar are produced annually, at 1,200 yuan per ton, worth 3 million yuan.

[0068] Bran residues are derived from biological straw, and each ton of straw is calculated at 550 yuan, and the annual efficiency increase is 2.25 million yuan.

[0069] The first process route ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com