Aqueous paint remover, and preparation method and application thereof

A paint stripper, water-based technology, used in chemical paint/ink removers, coatings, etc., can solve problems such as incomplete removal of workpieces and paint film residues, and achieve convenient maintenance, low corrosiveness, and corrosion of the bath. small effect

Inactive Publication Date: 2018-01-16

合肥普庆新材料科技有限公司

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the water-based paint remover on the market cannot remove the workpiece with special curved structure, and it is easy to have paint film residue, so there is a big defect in the paint removal effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0030] Example Preparation method: Dissolve the alkali metal salt in 70% water, stir and mix, then successively at least two organic solvents, solubilizers and sodium dichloroisocyanurate, fully stir and mix evenly, and finally add the remaining 30% of water, A homogeneous and stable water-based paint remover is obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

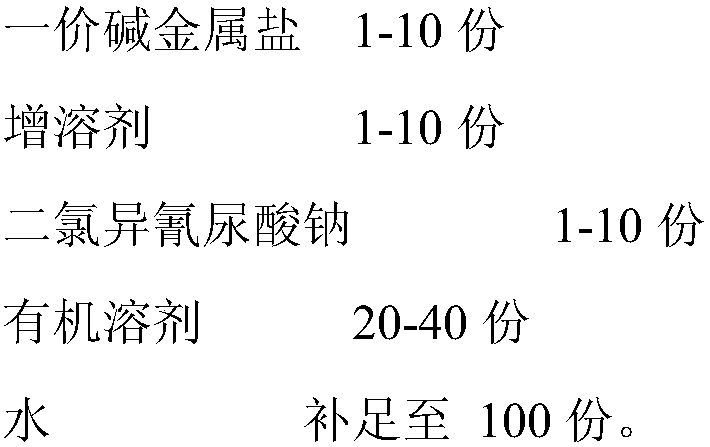

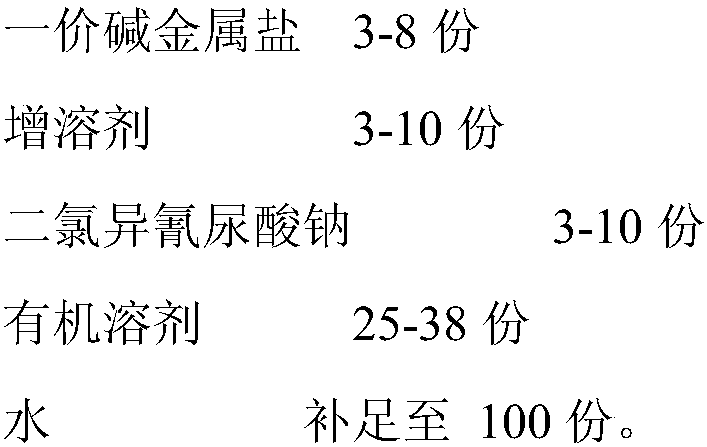

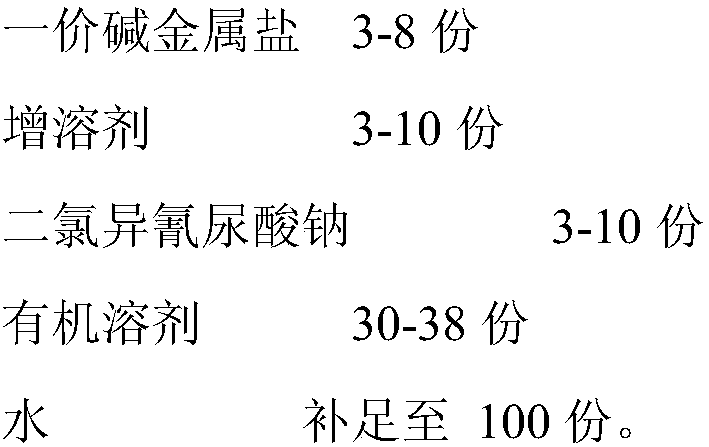

The invention relates to the technical field of metal coating, and concretely relates to an aqueous paint remover, and a preparation method and an application thereof. 100 parts of the aqueous paint remover comprise 1-10 parts of a monovalent alkali metal salt, 1-10 parts of a solubilizer, 1-10 parts of sodium dichloroisocyanurate, 20-40 parts of at least two organic solvents, and the balance of water. The preparation method comprises the following steps: dissolving the alkali metal salt in parts of the water, stirring and mixing the alkali metal salt and the water, sequentially adding at least three organic solvents, the solubilizer and the sodium dichloroisocyanurate, fully stirring and uniformly mixing all above materials, and finally adding the remaining water to obtain the homogenousand stable aqueous paint remover. The homogenous and stable aqueous paint remover is prepared under the action of an alkaline solution and the organic solvents through the synergism of the solubilizerand the sodium dichloroisocyanurate, can effectively dissolve all powdery coating and paint films and complex paint residues, and can effectively remove paint films from sprayed members having a special bent structure.

Description

technical field [0001] The invention relates to the technical field of metal coating, in particular to a water-based paint remover and its preparation and application. Background technique [0002] Metal surface painting is generally divided into two parts: one is the surface treatment of the metal before painting; the other is the construction of the painting. Coating construction is the process of attaching paint and coating to the metal surface by spraying, brushing, roller coating, etc., so as to protect and decorate the metal. Sometimes the painted products will produce defective products during the production process, and the coating will be damaged to varying degrees due to some external conditions, such as mechanical damage or erosion of the corrosive medium during the long-term use of the product, so it is necessary to remove the old The paint film is removed to facilitate secondary coating and utilization. [0003] The paint remover is widely used because it remo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D9/00

Inventor 何宗文侯伟何宗俊

Owner 合肥普庆新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com