Method for preparing plate-shaped all-ceramic-coated fuel pellets by integrated molding

A technology for coating fuel and ceramics, which is applied in the manufacture of reactors, reducing greenhouse gases, and reactors. It can solve the problems of difficulty in co-firing the fuel-free zone and SiC matrix ceramics, uneven distribution of TRISO particles, and difficulty in preparing the fuel-free zone. Achieve the effect of low cost, convenient engineering application and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

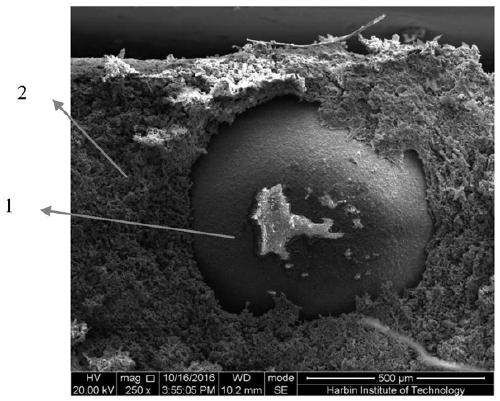

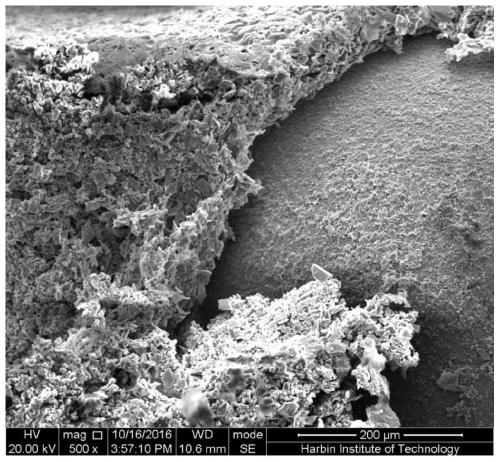

[0067] A method for preparing a plate-shaped full-ceramic-coated fuel pellet through integrated molding, comprising:

[0068] (1) SiC / TRISO composite green tape and single SiC green tape were prepared respectively;

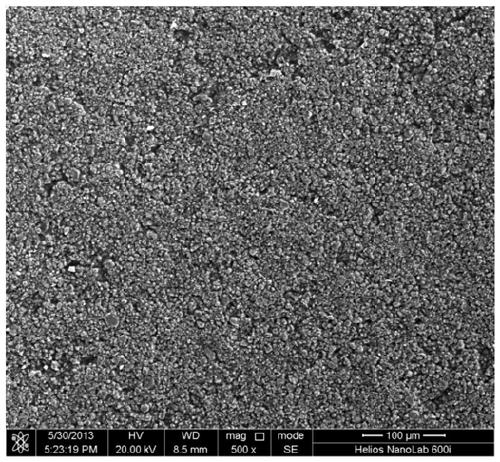

[0069] The specific preparation method is: mix SiC short fibers with a length of 2 o 3 and Y 2 o 3 . The ball milling medium is absolute ethanol, the mixing balls are dense SiC balls, the ball-to-material ratio is 10:1, the mixing time is 8 hours, and then dried at 60°C to obtain the mixed powder. Mix the obtained mixed powder with 35wt% solvent and 1% tetramethylammonium hydroxide, and ball mill for 8 hours to obtain a stable dispersed suspension; wherein the solvent is a mixed liquid composed of alcohol and toluene, and the volume ratio of alcohol to toluene in the mixed liquid is It is 2:3. Add 6wt% PVB, 3wt% dibutyl phthalate and 1wt% n-butanol to the suspension, mix for 2h, defoam under -0.1Pa vacuum condition for 30min, and obtain a stable dispersed SiC...

Embodiment 2

[0082] The difference between this embodiment and Embodiment 1 is that the process parameters of each step in this embodiment are different, and the specific settings are as follows:

[0083] (1) SiC / TRISO composite green tape and single SiC green tape were prepared respectively;

[0084] The specific preparation method is: mix SiC short fibers with a length of 2 o 3 and Y 2 o 3. The ball milling medium is absolute ethanol, the mixing balls are dense SiC balls, the ball-to-material ratio is 10:1, the mixing time is 8 hours, and then dried at 60°C to obtain the mixed powder. Mix the obtained mixed powder with 35wt% solvent and 1% tetramethylammonium hydroxide, and ball mill for 8 hours to obtain a stable dispersed suspension; wherein the solvent is a mixed liquid composed of alcohol and toluene, and the volume ratio of alcohol to toluene in the mixed liquid is It is 2:3. Add 5wt% PVB, 4wt% dibutyl phthalate and 1wt% n-butanol to the suspension, mix for 2h, defoam under -0....

Embodiment 3

[0097] The difference between this embodiment and embodiment 1 is that the sintering method in this embodiment is different, and the specific settings are as follows:

[0098] (a) When the sintering method is spark plasma sintering, the sintering process is:

[0099] The FCM green body after debinding is placed in a graphite mold and subjected to spark plasma sintering. The graphite mold size matches the FCM green body size. Sintering temperature: 1700°C, sintering pressure: 20MPa, holding time: 5min, sintering atmosphere: N 2 ; Vacuum degree: <1Pa. The process flow is: heat up to 1000°C at 50°C / min, hold for 1 minute; heat up to 1700°C at 100°C / min, hold for 5 minutes; cool down to 1000°C at 100°C / min, hold for 2 minutes, and then cool to room temperature with the furnace to obtain FCM fuel pellets.

[0100] (b) When the sintering method is pressure sintering, the sintering process is:

[0101] The debinding FCM green body is placed in a graphite mold and subjected to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com