Method for monitoring and diagnosing equipment operation states according to vibration algorithm

A technology for equipment operation and equipment, which is applied in the field of monitoring and diagnosing the operation state of equipment using vibration algorithms, can solve the problems such as difficulty in improving the accuracy of signal feature extraction, limited accuracy of signal feature analysis methods, and influence on signal feature extraction accuracy, etc. Achieve the effect of avoiding huge economic losses, avoiding catastrophic accidents, and improving economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

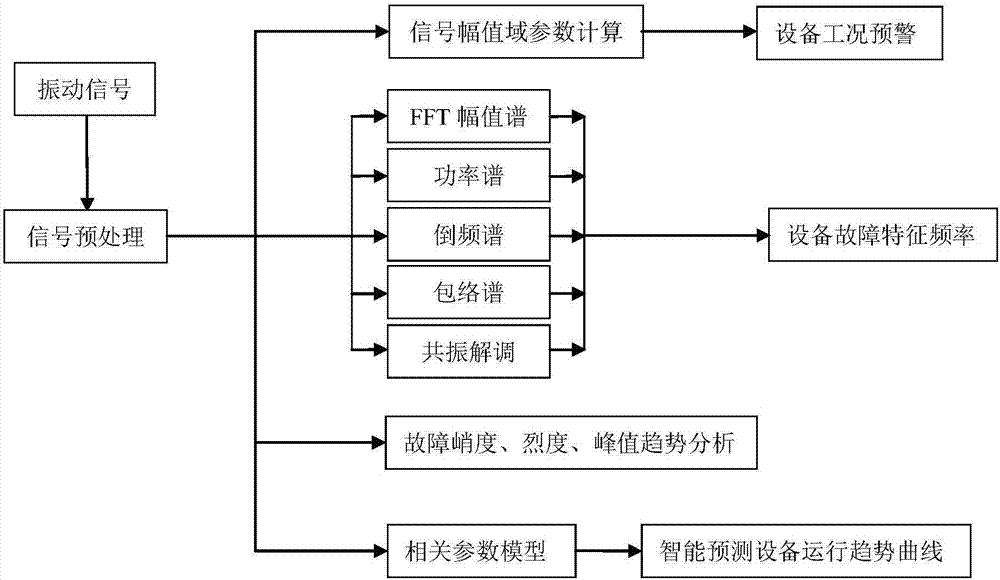

[0026] Such as figure 1 As shown, a method for monitoring and diagnosing the operating state of equipment using a vibration algorithm is characterized in that it includes the following process:

[0027] ① Perform signal preprocessing on the collected vibration signals of the equipment. Since the collected vibration signals inevitably contain noise, firstly perform noise reduction preprocessing on the collected vibration signals to reduce the interference of noise on the signal and improve the signal-to-noise According to the actual operation of the equipment, select the appropriate IIR filter for filtering; the filter forms include: Butterworth filter, Chebyshev filter, inverse Chebyshev filter, elliptic filter and Bessel filter ;

[0028] ②Calculate the amplitude field parameters of the preprocessed signal to realize the early warning of the equipment work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com