Preparation method for dual-emitting fluorescence carbon spot

A technology of dual emission fluorescence and carbon dots, which is applied in the direction of luminescent materials, fluorescence/phosphorescence, chemical instruments and methods, etc., can solve the problems of rare reports of dual emission wavelength fluorescent carbon dots, etc. The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

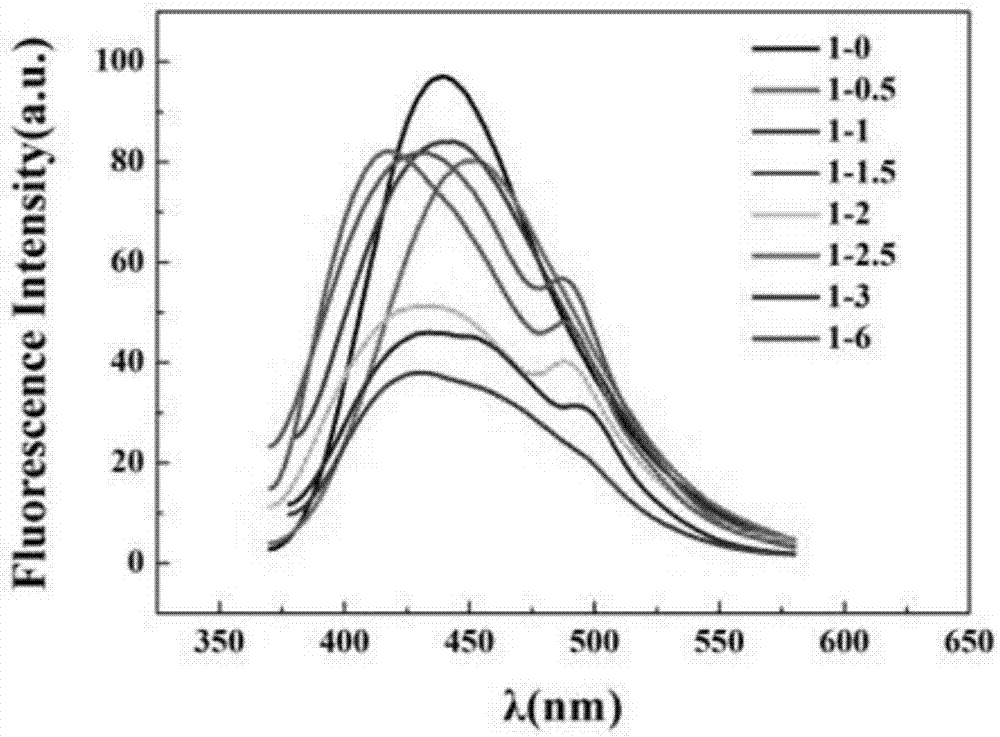

[0032] The influence of embodiment 1 raw material ratio on carbon point

[0033] 0.2mmol of 1-(2-pyridylazo)-2-naphthol and corresponding 0, 0.1mmol, 0.2mmol, 0.3mmol, 0.4mmol, 0.5mmol, 0.6mmol, 1.2mmol of copper chloride dihydrate Dissolve in eight centrifuge tubes filled with 10mL of absolute ethanol and sonicate for 20min; then, transfer the mixture to eight 25mL polytetrafluoroethylene reactors, and heat at 180°C for 4h; Cool naturally to room temperature and purify the product through a silica gel column. The eluent is a mixed solution of dichloromethane and methanol at a volume ratio of 40:1. The solvent is evaporated and dried in vacuo to obtain a carbon dot solid.

[0034] The obtained carbon dots were diluted with absolute ethanol to form a carbon dot mother solution with a concentration of 1 mg / mL, 200 μL was taken, and the volume was adjusted to 2 mL with water, and the fluorescence spectrum was measured with an F-7000 fluorescence spectrophotometer. When the excita...

Embodiment 2

[0035] The influence of embodiment 2 solvent on carbon point

[0036] Accurately weigh 0.2mmol of 1-(2-pyridylazo)-2-naphthol and 0.4mmol of copper chloride dihydrate in seven parts respectively, and fill them with 10mL of absolute ethanol, 8mL of absolute ethanol and 2mL of ultrapure Mixed solution of water, mixed solution of 6mL absolute ethanol and 4mL ultrapure water, mixed solution of 5mL absolute ethanol and 5mL ultrapure water, mixed solution of 4mL absolute ethanol and 6mL ultrapure water, 2mL absolute ethanol and 8mL Dissolve the mixed solution of ultrapure water and a centrifuge tube of 10mL ultrapure water and sonicate for 20min; then, transfer the mixed solution to seven 25mL polytetrafluoroethylene reactors respectively, and heat at 180°C for 4h; after the reaction is completed, wait for the reaction The kettle was naturally cooled to room temperature, and the product was purified through a silica gel column. The eluent was a mixed solution of dichloromethane and ...

Embodiment 3

[0038] The influence of embodiment 3 temperature of reaction on carbon point

[0039] In three centrifuge tubes, accurately weigh 0.2mmol of 1-(2-pyridylazo)-2-naphthol and 0.4mmol of copper chloride dihydrate dissolved in 10mL of absolute ethanol and sonicate for 20min; then, the mixed The solution was transferred to three 25mL polytetrafluoroethylene reaction kettles, and heated and reacted at 170°C, 180°C, and 190°C for 4 hours respectively; after the reaction was completed, the reaction kettles were naturally cooled to room temperature, and the product was purified through a silica gel column. It is a mixed solution of dichloromethane and methanol with a volume ratio of 40:1. The solvent is evaporated and vacuum-dried to obtain a carbon dot solid.

[0040] Adopt the method identical with embodiment 1 to obtain its fluorescence spectrogram ( image 3 ), the carbon dots produced at 180°C had the strongest fluorescence peak at 488nm wavelength, and a small amount of product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com