A method for preparing cobaltous oxide microspheres by solution method

A technology of cobalt oxide and microspheres, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of cumbersome process, high cost, complicated process, etc., and achieve the effects of simple process, low energy consumption and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

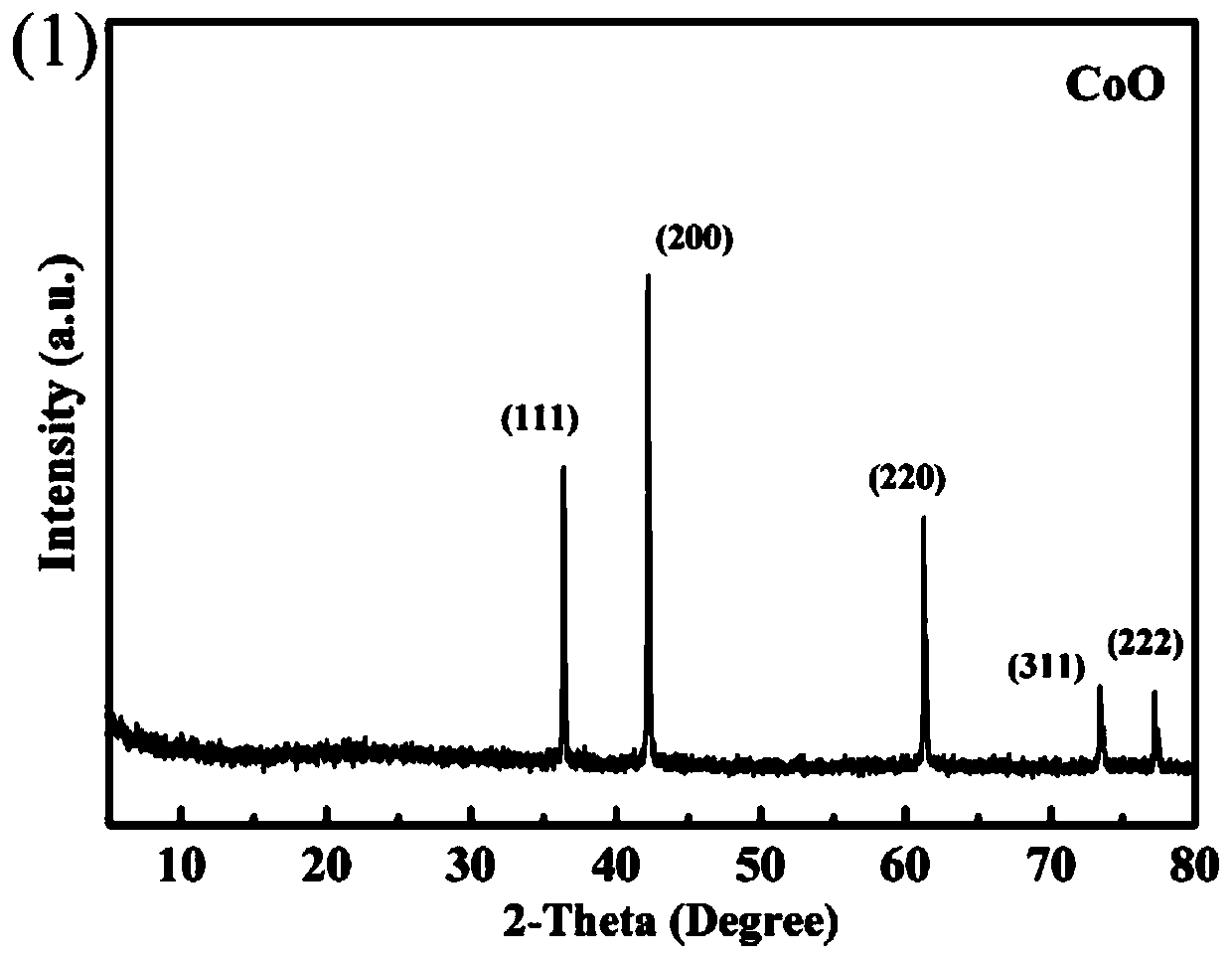

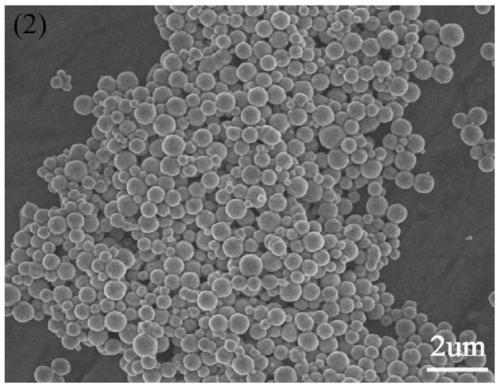

[0017] Weigh 0.6g of cobalt acetate tetrahydrate and dissolve it in a mixed solution composed of 55mL of ethylene glycol and 5mL of deionized water, stir to make it fully mixed and dissolved, transfer the above solution to a reaction kettle with a volume of 100mL, and put the closed reaction kettle in Preheat the oven to 140°C in advance, and raise the temperature of the oven to 200°C at a rate of 2°C / min, and then keep it at 200°C for 8 hours; after the reaction is completed, the reaction kettle is cooled to room temperature, and the mixture is filtered , washing, and drying to obtain CoO microspheres. The XRD pattern of gained CoO microsphere is as figure 1 As shown, it can be seen from the figure that the product is pure face-centered cubic cobaltous oxide, and there are no other impurity diffraction peaks; the SEM microscopic appearance of CoO microspheres is as follows figure 2 shown.

Embodiment 2

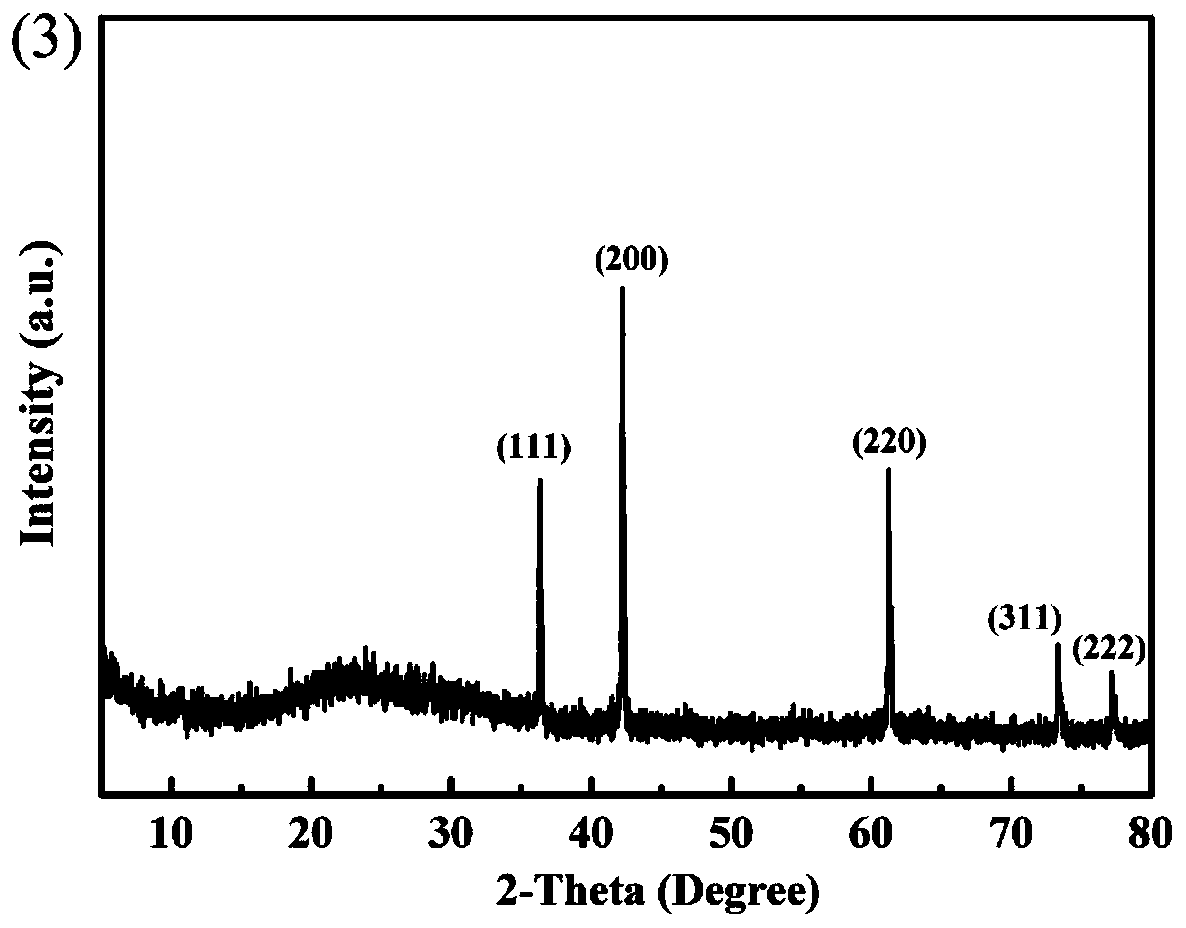

[0019] Weigh 1.3g of cobalt acetate tetrahydrate and dissolve it in a mixed solution composed of 60mL of ethylene glycol and 6.6mL of deionized water, stir to make it fully mixed and dissolved, transfer the above solution to a reaction kettle with a volume of 90mL, and put the closed reaction kettle into In the oven preheated to 150°C in advance, and the oven was heated to 210°C at a rate of 5°C / min, and then kept at 210°C for 9 hours; after the reaction was completed, the reaction kettle was cooled to room temperature, and the mixture was passed through After filtering, washing and drying, CoO microspheres are obtained. The XRD pattern of gained CoO microsphere is as image 3 As shown, it can be seen from the figure that the product is cobaltous oxide of face-centered cubic and hexagonal crystal systems, without diffraction peaks of other impurities; the SEM morphology of the resulting CoO microspheres is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com