Preparation device and method of sodium carbonate and ammonium sulfate by anhydrous sodium sulphate

A technology of ammonium sulfate and Yuanming powder, applied in the direction of ammonium sulfate, carbonate preparations, reagents, etc., can solve the problems of low matching degree and cumbersome operation, and achieve the guarantee of purity, cumbersome operation, and easy adjustment and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

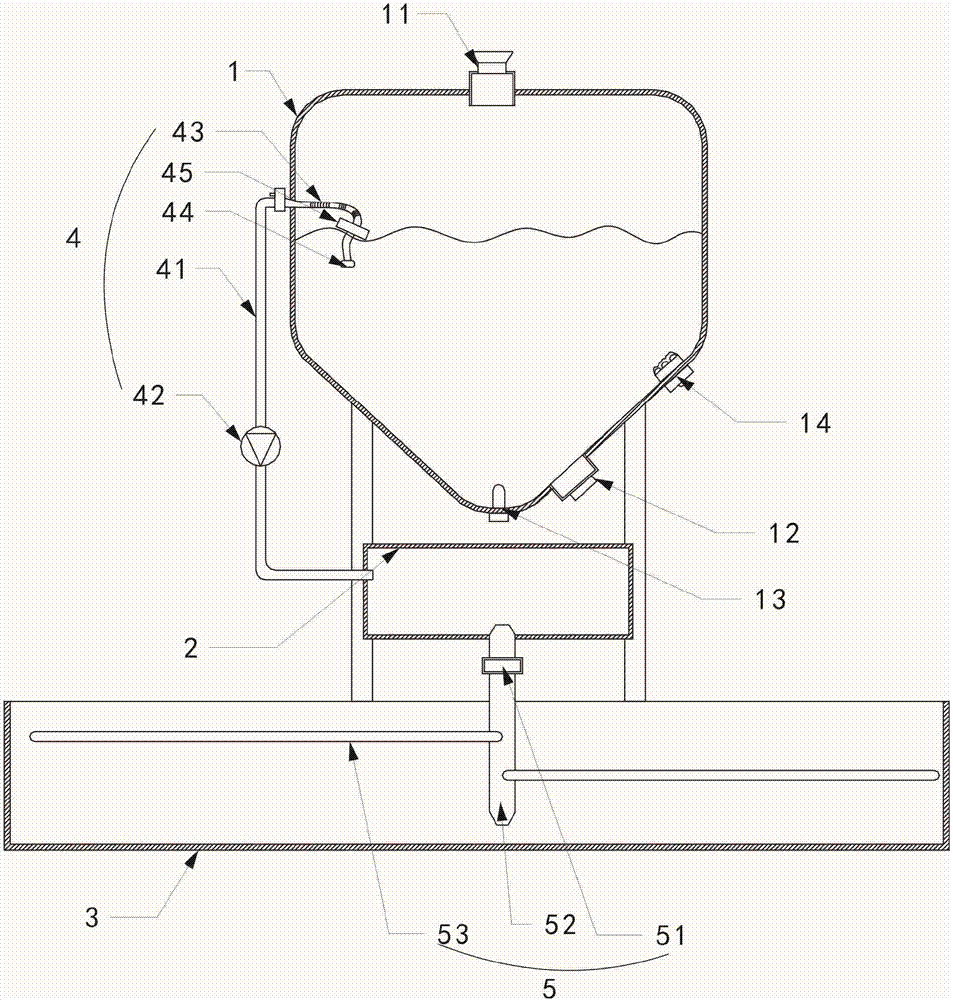

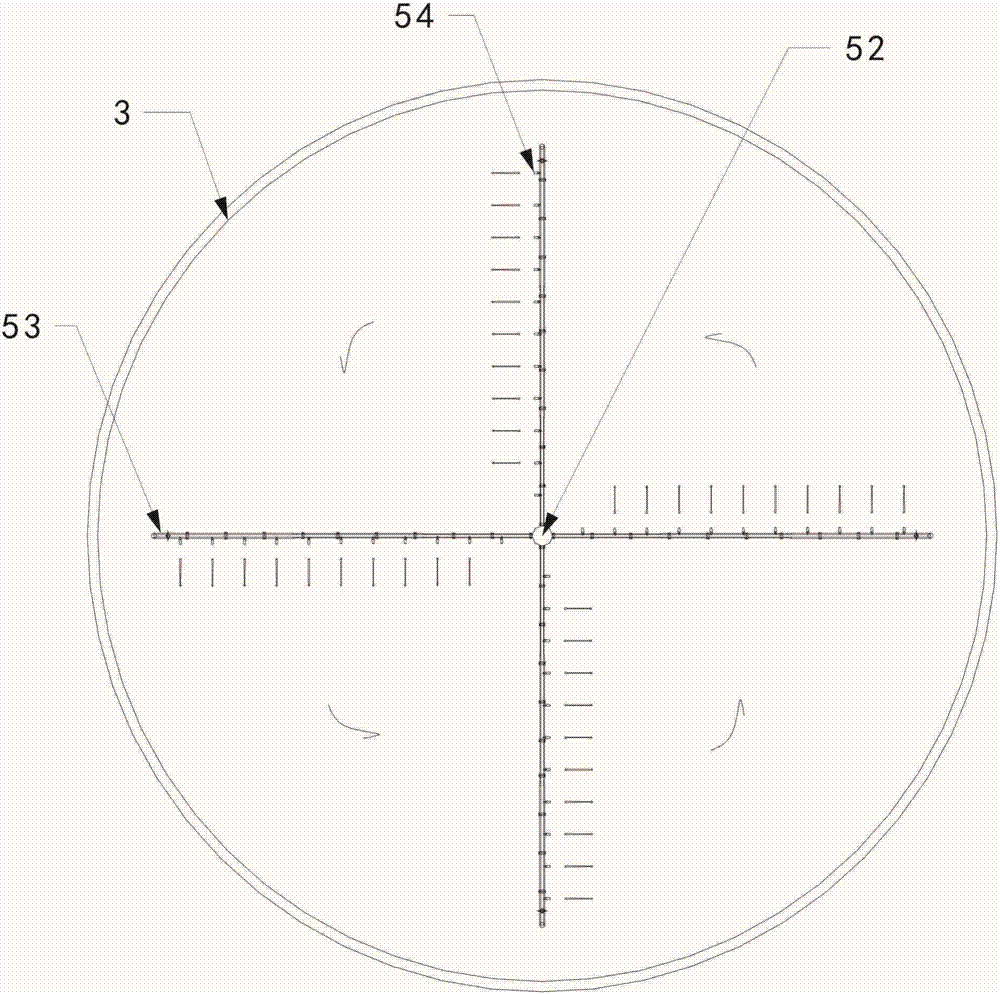

[0030] As shown in the figure, this embodiment provides a device for preparing soda ash and ammonium sulfate from sodium sulfate, including a reaction kettle 1, a temperature control box 2, a stirring tank 3, and an extraction mechanism 4 for transferring intermediate liquids. The kettle 1 is installed above the stirring tank 3 through the support legs 5, the four corners of the support legs 5 are welded on the edge of the stirring tank 3, the temperature control box 2 is fixed on the support legs 5, and the extraction mechanism 4 is connected with the reaction kettle respectively. 1 communicates with the temperature control box 2. The inside of the reaction kettle 1 is a ceramic lining.

[0031] The working principle of this embodiment is as follows: using sodium sulfate to prepare soda ash and ammonium sulfate requires constant temperature regulation and stirring, the existing equipment cannot be well adapted, the operation is cumbersome, and the matching degree is not high....

Embodiment 2

[0033] This embodiment has been optimized as follows on the basis of Embodiment 1: the extraction mechanism 4 of this embodiment includes an anti-corrosion pipeline 41, a water suction pump 42, a telescopic tube 43, a water suction cover 44, and a floating ball 45, and the anti-corrosion pipeline 41 respectively connected with the upper end of the reaction kettle 1 and the upper end of the temperature control box 2; The ball 45 communicates with the telescopic tube 43 .

[0034] The working principle of this embodiment is as follows: During the preparation process, heavy metals need to be precipitated in the reactor 1 first, and then the liquid is transferred to the temperature control box 2. When the liquid is transferred, it is easy to bring the precipitated heavy metals together, affecting The quality of the finished product, in response to this problem, this device uses a float 45, a water-absorbing cover 44 and a telescopic tube 43, the float 45 floats up and down followi...

Embodiment 3

[0036] The present embodiment has been optimized as follows on the basis of Embodiment 1: the reaction kettle 1 of the present embodiment also includes a feed port 11, a slag discharge port 12, a pH meter 13, a temperature controller 14, and the feed port 11 Located at the top of the reactor 1, the slag outlet 12 is opened on the lower side wall of the reactor 1, the pH meter 13 is installed at the bottom of the reactor 1, and the temperature controller 14 is fixed on the shell of the reactor 1 superior.

[0037]The working principle of this embodiment is as follows: Since the pH value of the mixed solution needs to be controlled at any time during the reaction process, in order to realize the rapid measurement of the pH value, the device installs the pH meter 13 at the bottom of the reaction kettle 1 to read the solution in real time. The PH value improves the working efficiency of the device. The long-term accumulation of heavy metals in the reaction kettle 1 will easily af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com