A stamping die for automatic material pushing of auto parts

A technology for stamping dies and auto parts, applied in the field of stamping dies, can solve the problems of reduced stamping accuracy, cumbersomeness, and high cost, and achieve the effects of improving stamping efficiency and processing quality, improving stamping accuracy, and improving stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

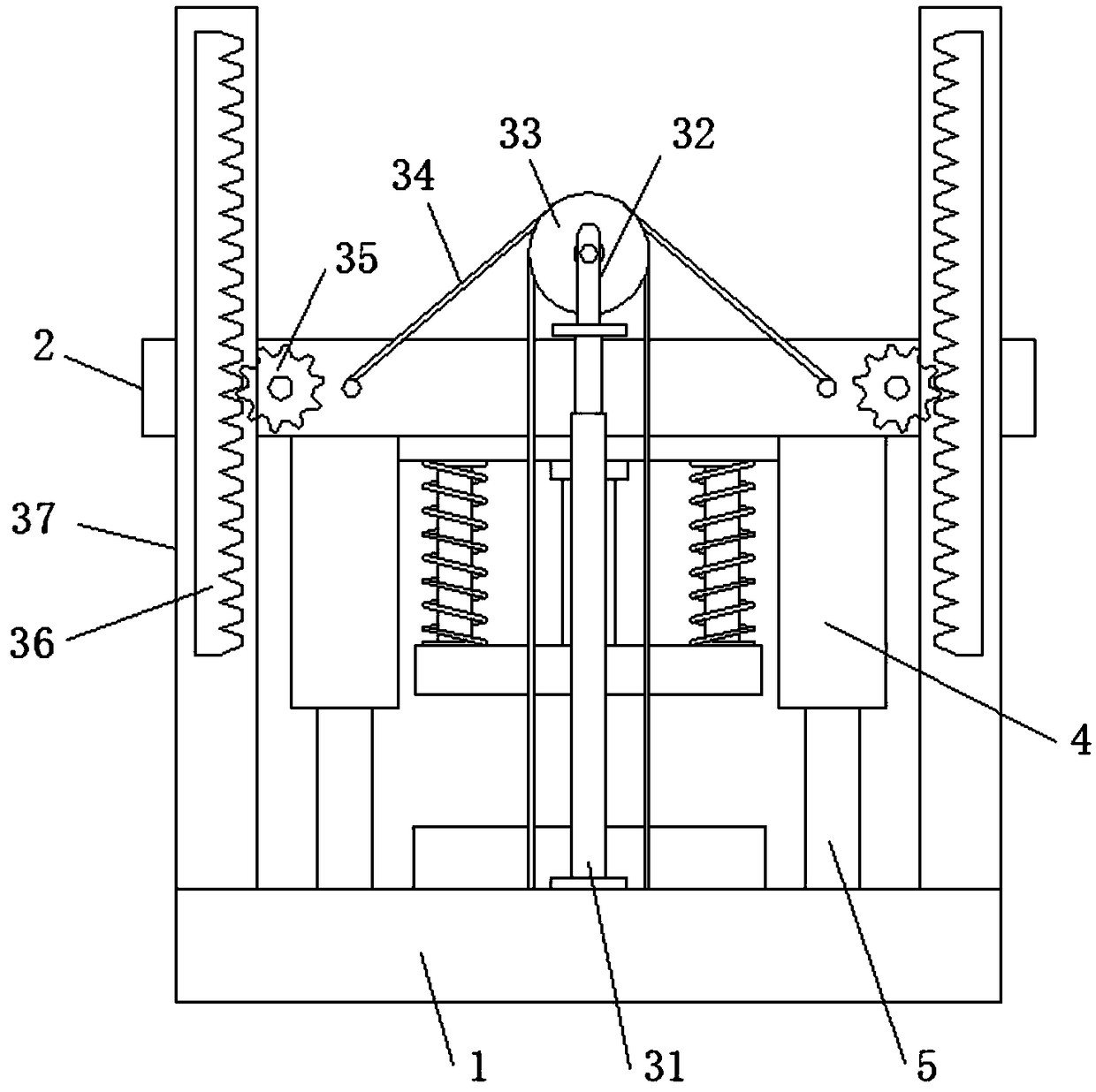

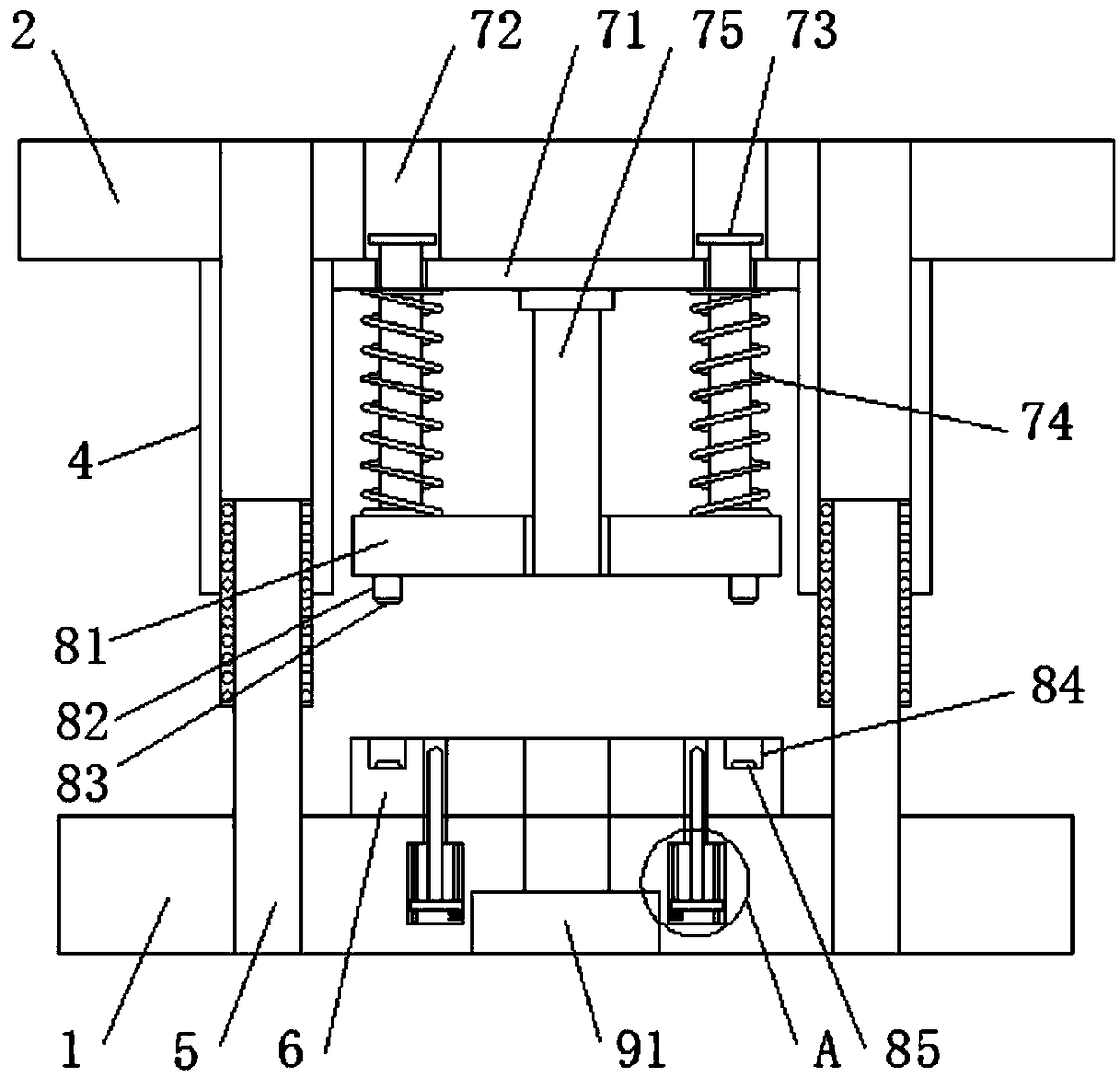

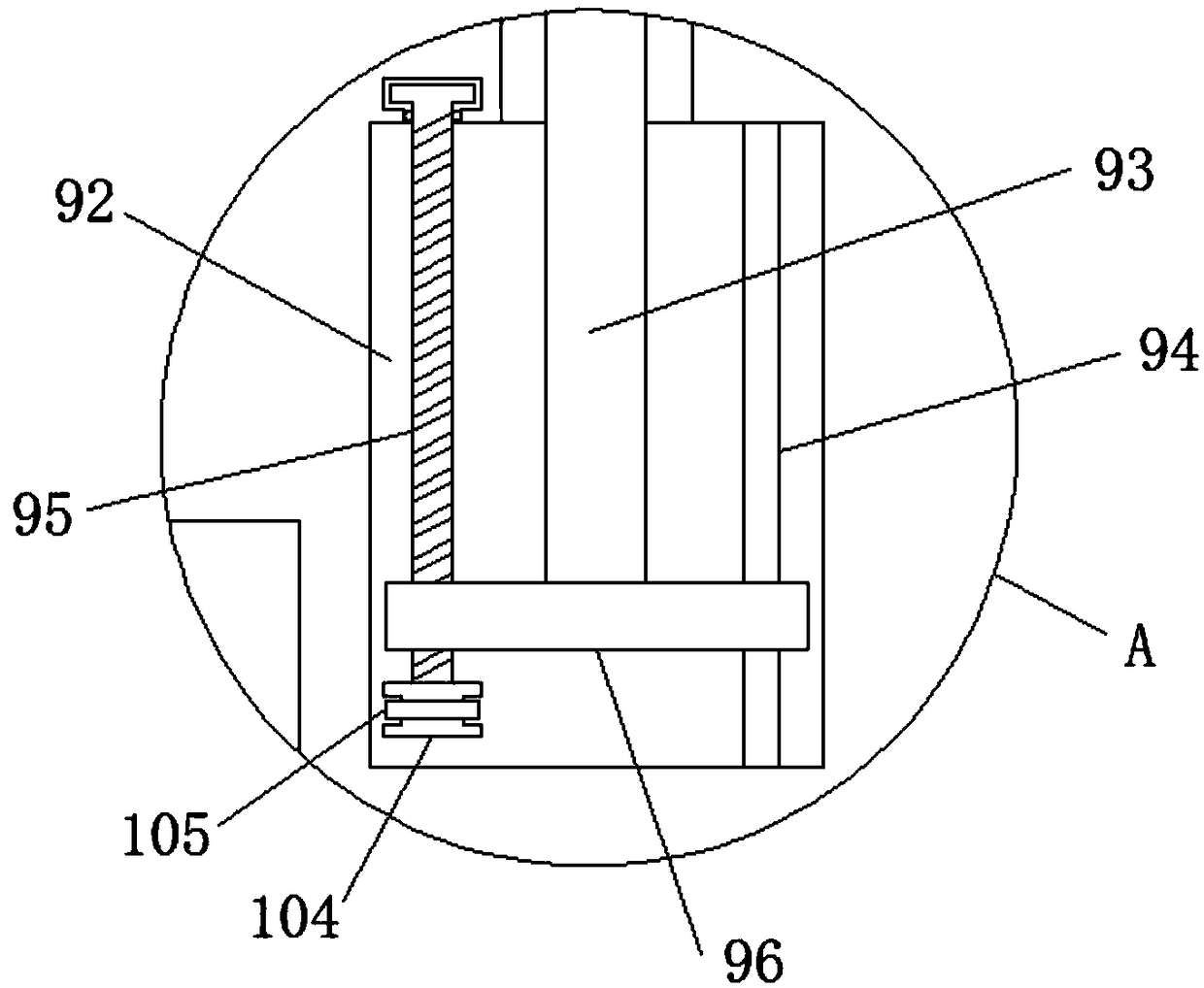

[0029] refer to Figure 1-4 , a stamping die for automatic material pushing of auto parts, comprising a bottom plate 1 and a top plate 2 arranged in parallel, the bottom plate 1 is located directly below the top plate 2, and also includes a stable lifting mechanism arranged between the bottom plate 1 and the top plate 2. The buffer mechanism at the bottom of the top plate 2 and the automatic pushing mechanism inside the bottom plate 1;

[0030] The smooth lifting mechanism includes two groups of hydraulic cylinders 31 and positioning plates 37 vertically installed on the top of the base plate 1, wherein the two groups of hydraulic cylinders 31 and positioning plates 37 are located on both sides of the top plate 2, and the top piston rod of the hydraulic cylinders 31 is equipped with U Shaped frame 32, the inner rotation of U-shaped frame 32 is equipped with pulley 33, is wound with two groups of steel ropes 34 on the pulley 33, and one end of steel rope 34 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com