Silicon-based micro gas chromatography column with high separation efficiency and preparation method thereof

A technology for micro gas chromatography and separation efficiency, which is applied in the field of silicon-based micro-gas chromatography columns and their preparation, can solve the problem that the separation efficiency of silicon-based micro-gas chromatography columns is difficult to be further improved, achieves good thermal stability and mechanical strength, improves the The effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

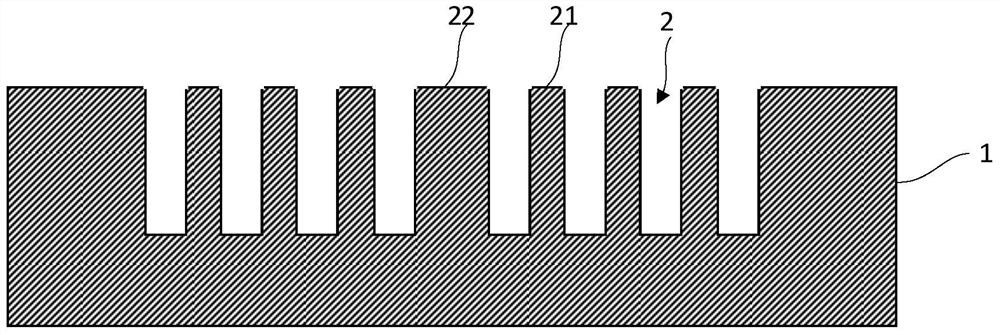

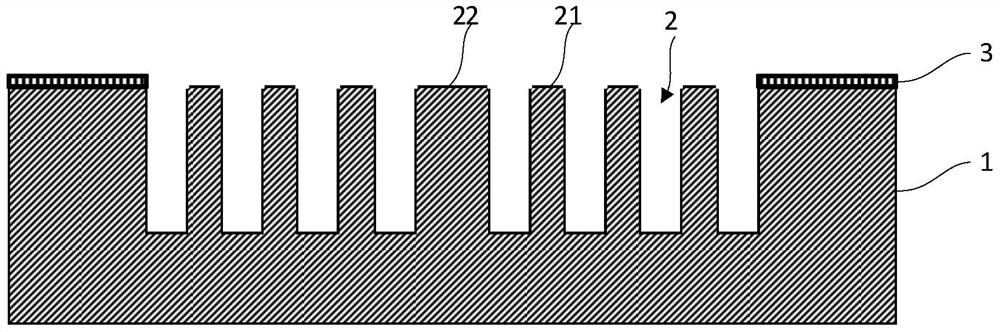

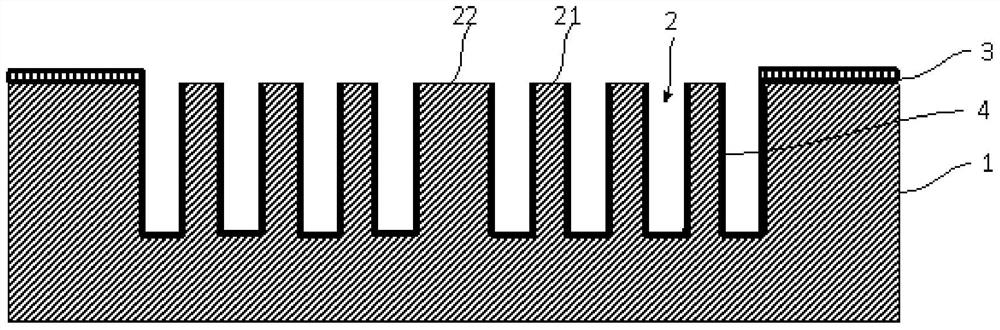

[0048] Such as Figure 1 to Figure 8 and Figure 12 As shown, the present embodiment provides a preparation method of a silicon-based micro gas chromatography column with high separation efficiency, and the preparation method comprises steps:

[0049] Step 1), making a microchannel 2 and a microfluidic port 23 on the silicon substrate 1, wherein the microchannel 2 also has a plurality of channel units or and / or microcolumn 21 arrays;

[0050] Step 2), making a mask film layer 3 to protect the bonding surface on the silicon substrate 1;

[0051] Step 3), constructing nano-mesoporous silicon oxide 4 in the microchannel 2, and removing the mask layer 3 before firing, wherein, the nano-mesoporous silicon oxide 4 is simultaneously constructed on the plurality of channel unit or and / or surface of the array of micropillars 21;

[0052] As an example, the non-aqueous synthesis method of self-assembly induced by solvent volatilization is used to construct nano-mesoporous silicon oxi...

Embodiment 2

[0079] This embodiment provides a method for preparing a silicon-based micro-gas chromatographic column with high separation efficiency. The basic steps are as in Example 1, wherein, the difference from Example 1 is that after step 5) is completed, a step of nano-intermediation is added. Porous silica 4 functionalized. Step 6), based on the components to be separated, a corresponding modification material 6 is formed on the surface of the nano-mesoporous silicon oxide 4, such as Figure 5 As shown, in this embodiment, the modification of octadecyltrichlorosilane (OTS) on the surface of nano-mesoporous silicon oxide 4 is described as an example, including steps:

[0080] Step 6-1), add 10ml of toluene and 0.1ml of OTS to a small well-sealed glass bottle, and use a syringe to inject this configured OTS toluene solution from one port into the silicon-based micro gas chromatography column chip until the solution Flow out from the other port, seal both ends of the chromatographic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com