Quartz vacuum sensor with electrodeless tuning fork

A vacuum sensor and electrodeless technology, which is applied in the direction of vacuum gauges that measure changes in gas frictional resistance, can solve the problems of poor stability and reliability of vacuum sensors, narrow ranges, and poor sensitivity, so as to reduce mechanical fatigue and improve sensitivity , Eliminate the effect of temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

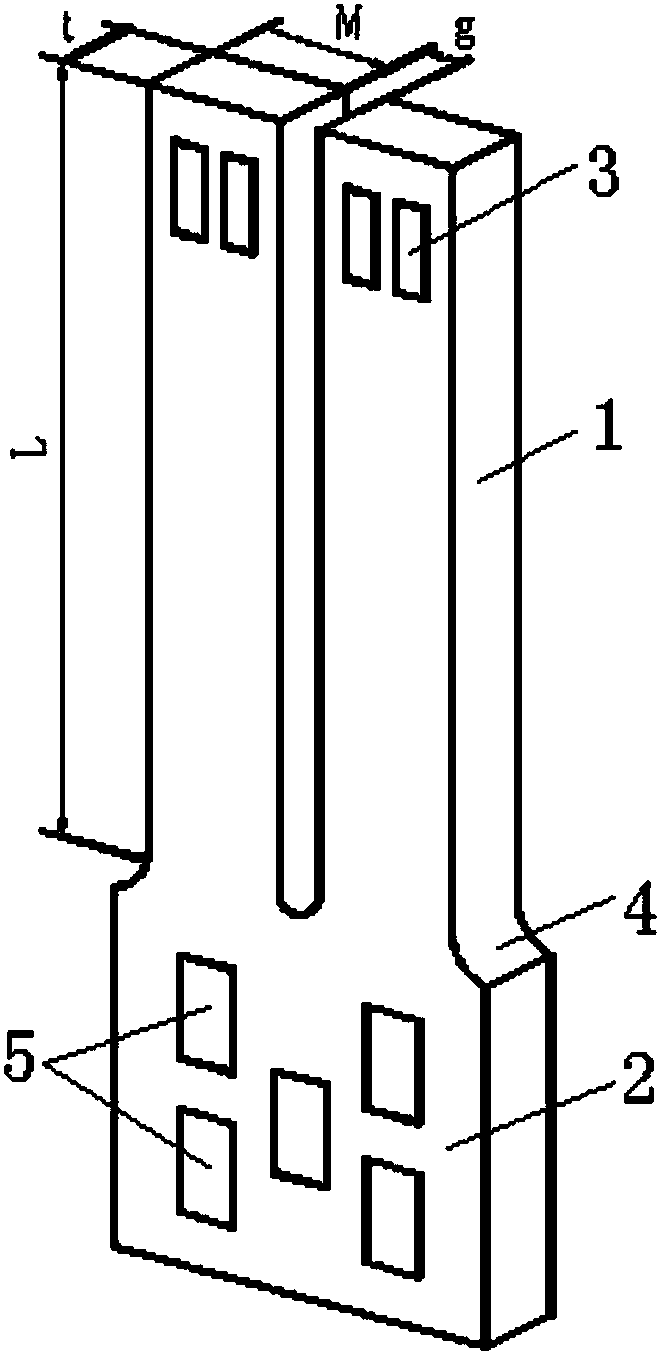

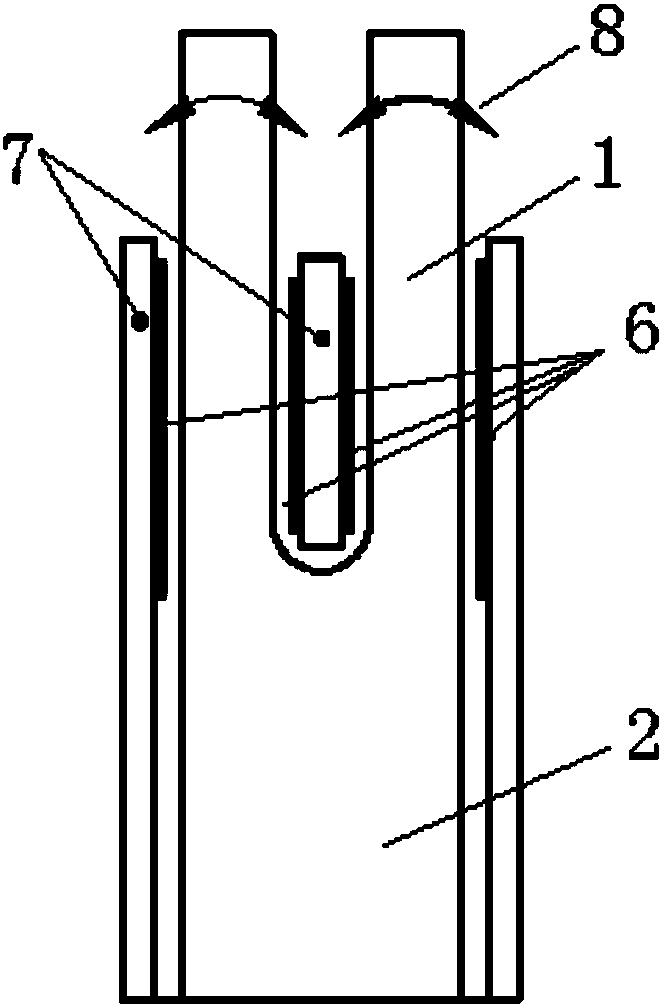

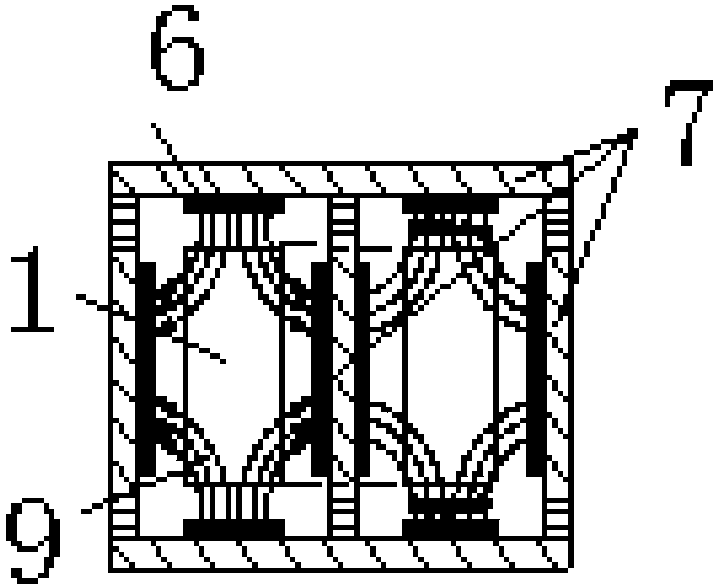

[0053] Specific implementation mode one: refer to Figure 1 to Figure 3 This embodiment is described in detail. The quartz vacuum sensor with an electrodeless resonant tuning fork described in this embodiment includes two tuning fork fork arms 1, a support isolation area 2, a metal electrode 6 and a quartz wafer 7,

[0054] The support isolation area 2 and the two tuning fork arms 1 are rectangular structures, the two tuning fork arms 1 have the same structure, the two tuning fork arms 1 are arranged at both ends of the upper surface of the support isolation area 2, and the two tuning fork arms There is a gap between 1, the support isolation area 2 and the two tuning fork arms 1 are in one piece structure,

[0055] Each tuning fork fork arm 1 is provided with an arc-shaped groove 4 at the edge connection between the fork arm 1 and the support isolation area 2,

[0056] Two parallel transparent grooves 3 are opened on the front surface of each tuning fork arm 1 near the top, ...

Embodiment

[0064] The quartz tuning fork is produced by the mechanical fork cutting method, the cutting shape is (zyw)-18°15', the thickness of the fork arm of the tuning fork is 5.2mm, and t / g=10. Two parallel rectangular through slots 3 are opened on the front surface of each tuning fork arm near the top, and arc-shaped grooves 4 are respectively made on the outer edges of the two tuning fork arms. , 5 rectangular slots were machined with the center line of each tuning fork arm as the axis of symmetry. Cut-shaped quartz plates parallel to the fork arms of the tuning fork are respectively inserted between the front and back, the left and the right, and between the two fork arms of the tuning fork. The distance between each of the quartz wafers and the fork arm of the tuning fork is equal to the integer multiple of the resonant wavelength of the fork arm of the tuning fork, and chromium-gold film electrodes are respectively prepared on the surface of the quartz wafer facing the fork arm ...

specific Embodiment approach 2

[0081] Specific embodiment 2: This embodiment is a further description of the quartz vacuum sensor with electrodeless resonant tuning fork described in specific embodiment 1. In this embodiment, the gap between two tuning fork fork arms 1 is equal to two tuning fork forks Integer multiples of the resonant wavelength of arm (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com