Oil returning device and oil returning method of refrigerating system

A refrigeration system and electrical control technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., to achieve the effect of safe use, simple structure, and elimination of lubricating oil blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the described embodiments should not be interpreted in a limiting manner.

[0028] In order to facilitate the understanding of the oil return problem in the vapor compression refrigeration system operating at extremely low temperature, this embodiment takes the refrigeration system of a vacuum freeze dryer as an example to specifically illustrate the technical solution of the present invention.

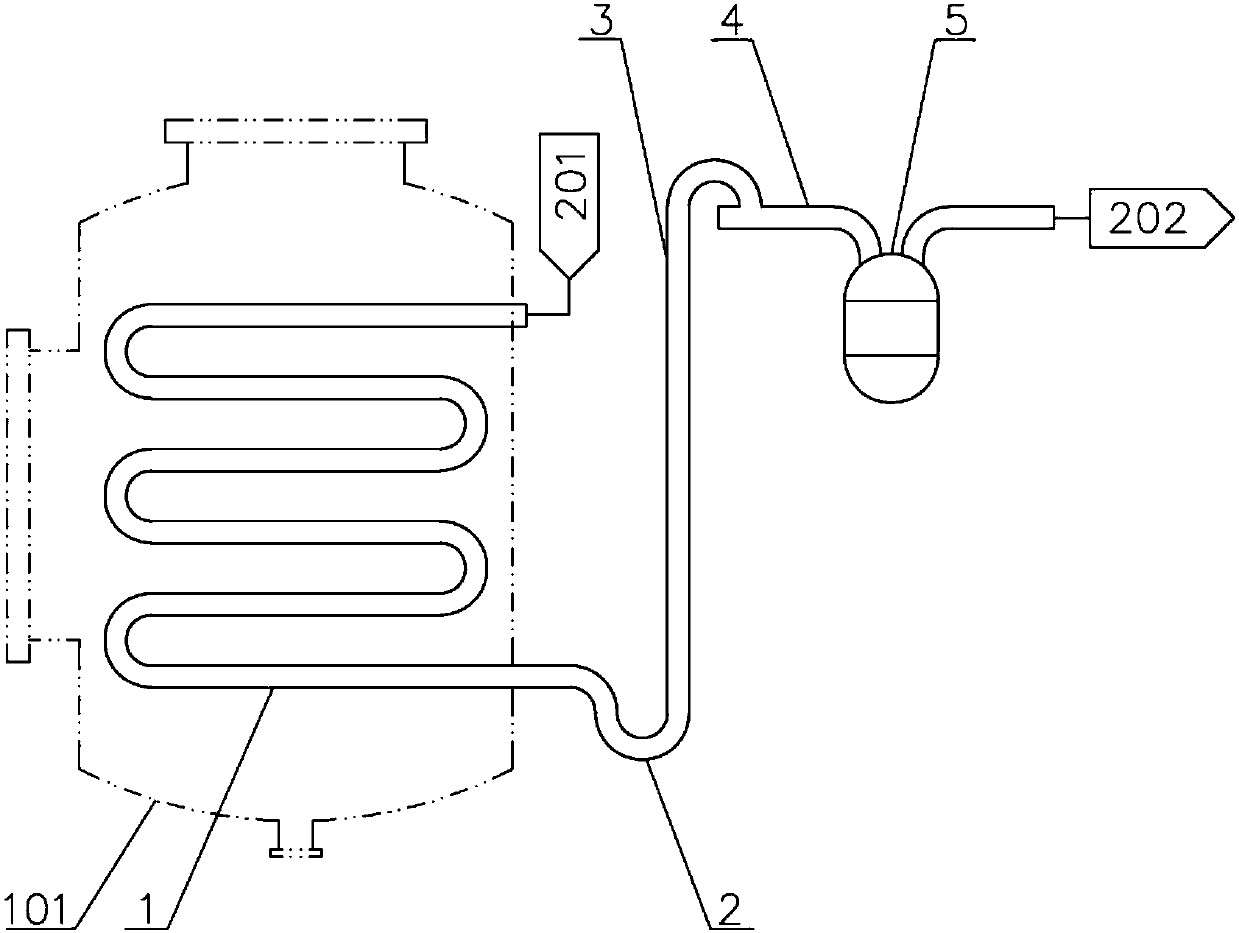

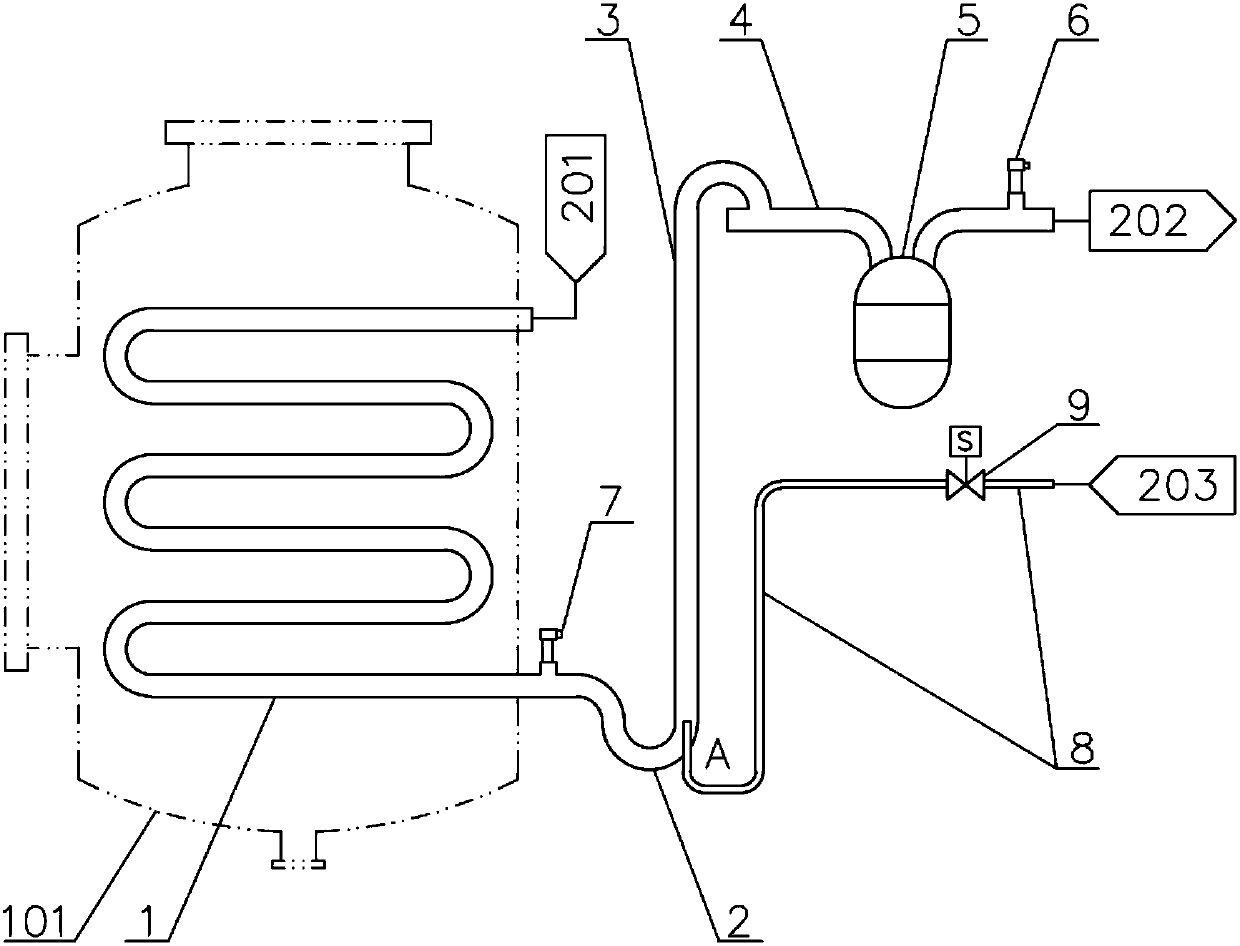

[0029] Refer to attached figure 2 As shown, the oil return device of the refrigeration system in this embodiment includes an evaporator 1, an oil trap 2, an ascending riser 3, a horizontal horizontal pipe 4 and a gas-liquid separator 5 connected in sequence, and the inlet of the evaporator 1 is used to communicate with the The discharge port 201 of the throttling device of the refrigeration system is connected, and the discharge port of the gas-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com