Two-stage compressor with built-in economizer

A two-stage compressor and economizer technology, applied in the field of compressors, can solve problems such as high cost, large space occupation, and complex structure, and achieve the effects of low cost, improved heat exchange efficiency, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

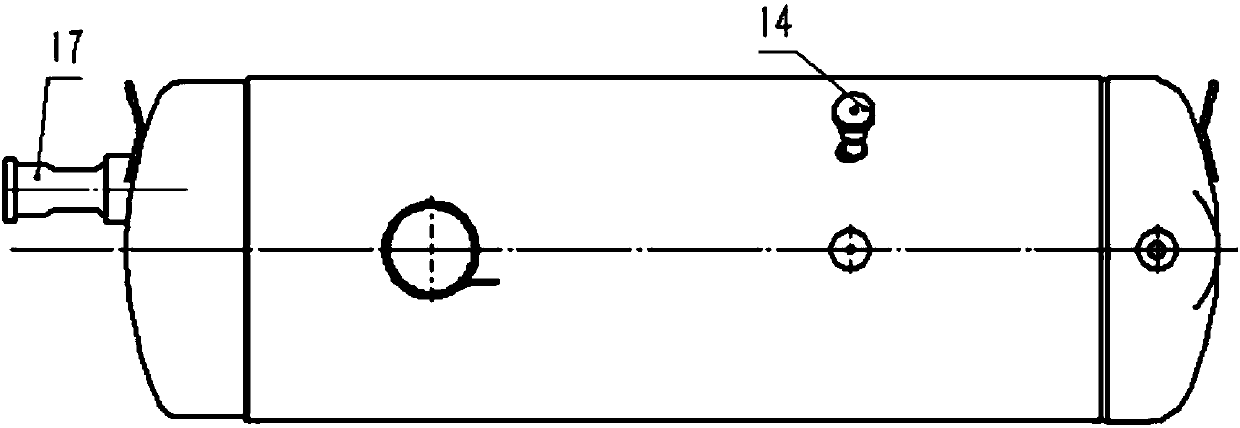

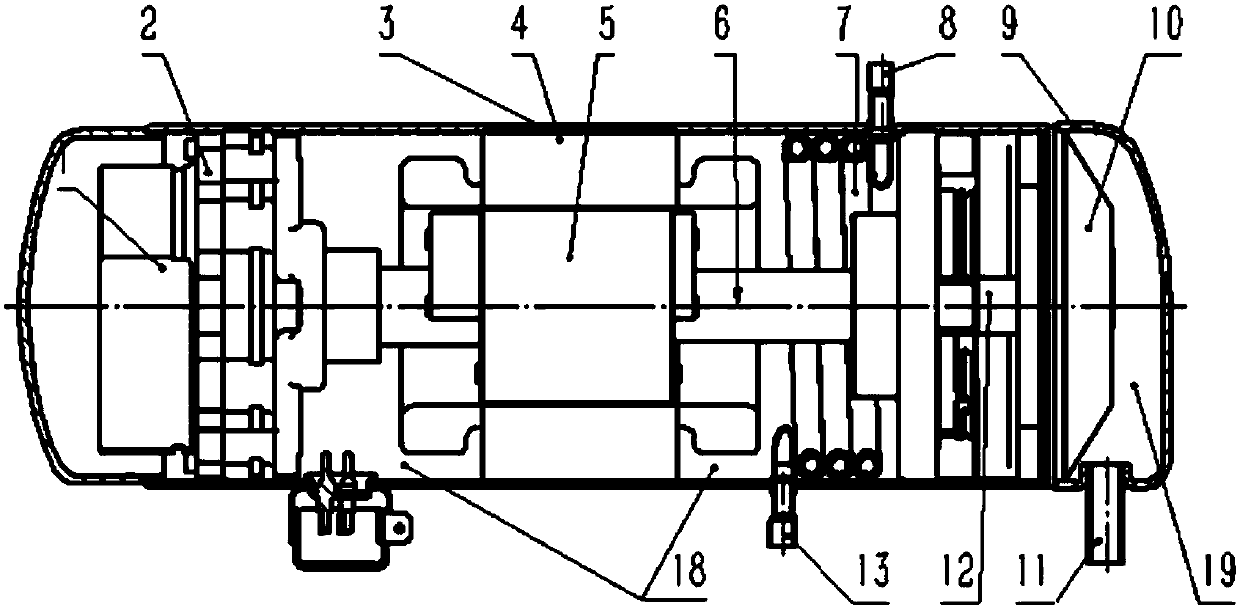

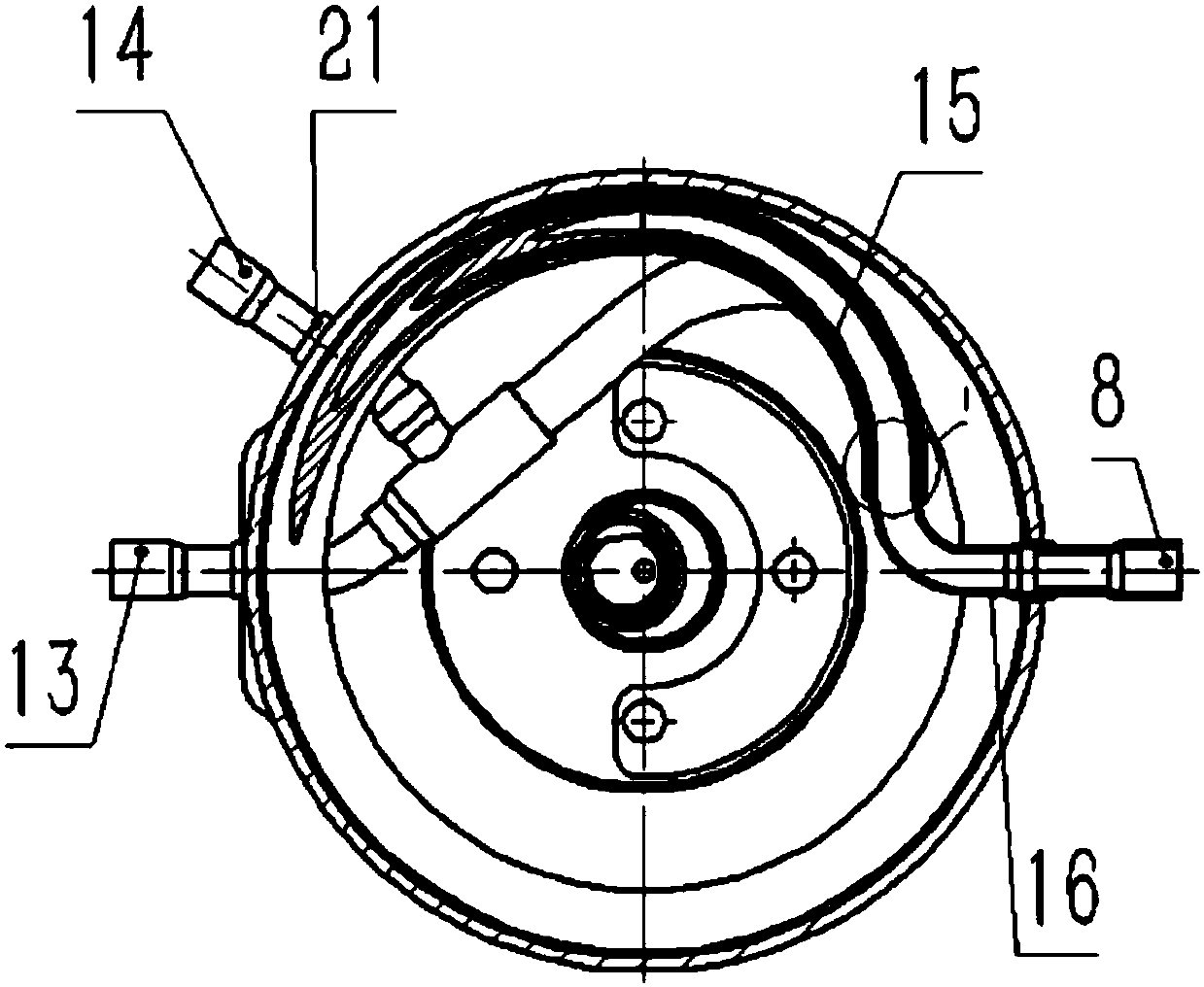

[0022] See attached picture.

[0023] A built-in economizer type two-stage compressor, including a casing 3, a horizontal and straight drive crankshaft 6 is arranged inside the casing 3, and the characteristic is that a pump assembly I2 is installed on one end of the drive crankshaft 6, and a pump assembly I2 is installed on the other end A pump assembly II12 is installed, and a high and low pressure isolation plate 10 is installed on the outside of the pump assembly II12. The two ends of the housing 3 are sealed by end caps I1 and II9 to form a closed chamber. The plate 10 will divide the chamber into a chamber I18 and a chamber II19, and the two chambers are communicated with a suction pipe 19 and an exhaust pipe 17 respectively, and the pump assembly II12 inside the chamber I18 drives the crankshaft 6 An economizer 7 is provided on the upper cover.

[0024] A motor stator 4 and a motor rotor 5 are installed on the drive crankshaft 6 in the housing 3 .

[0025] The pump as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com