A rail loading machine

A car loading machine and track-type technology, which is applied in the direction of mine roof supports, mining equipment, pillars/supports, etc., can solve the problems of large accumulation of floating coal and floating gangue, difficulty in transporting supports, broken wire ropes, etc., and reduce auxiliary operations The effect of flexible adjustment of workload, loading and unloading position, and low maintenance requirements of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

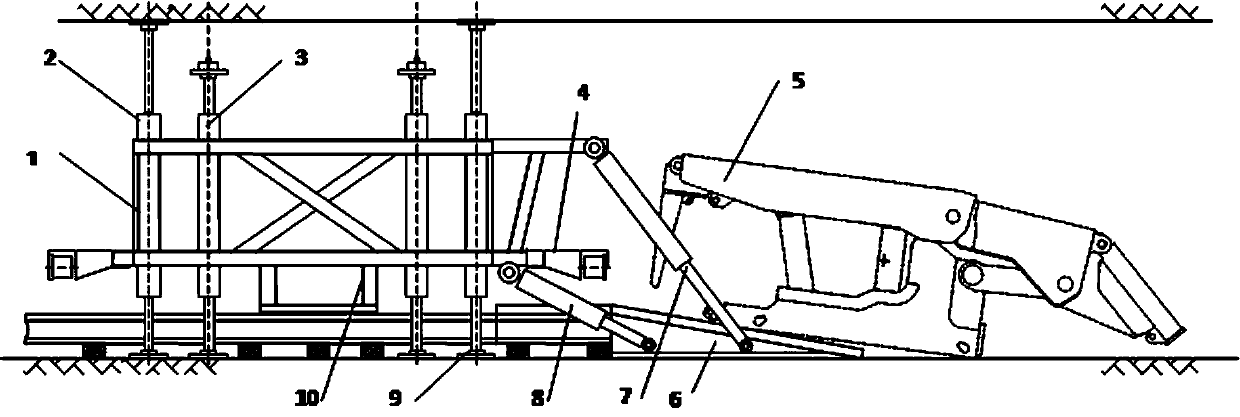

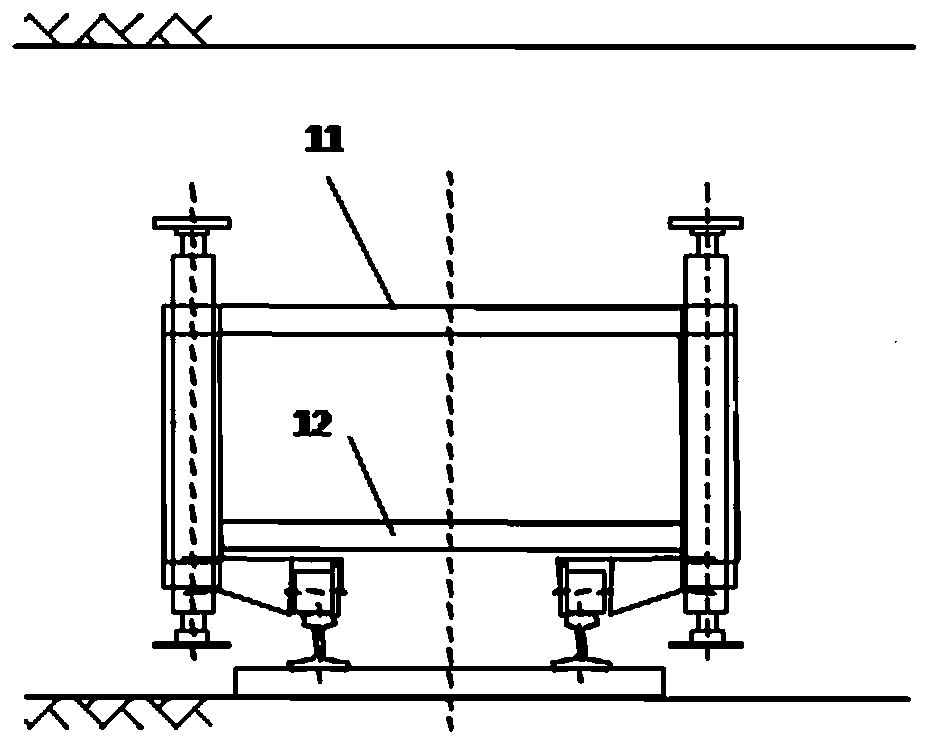

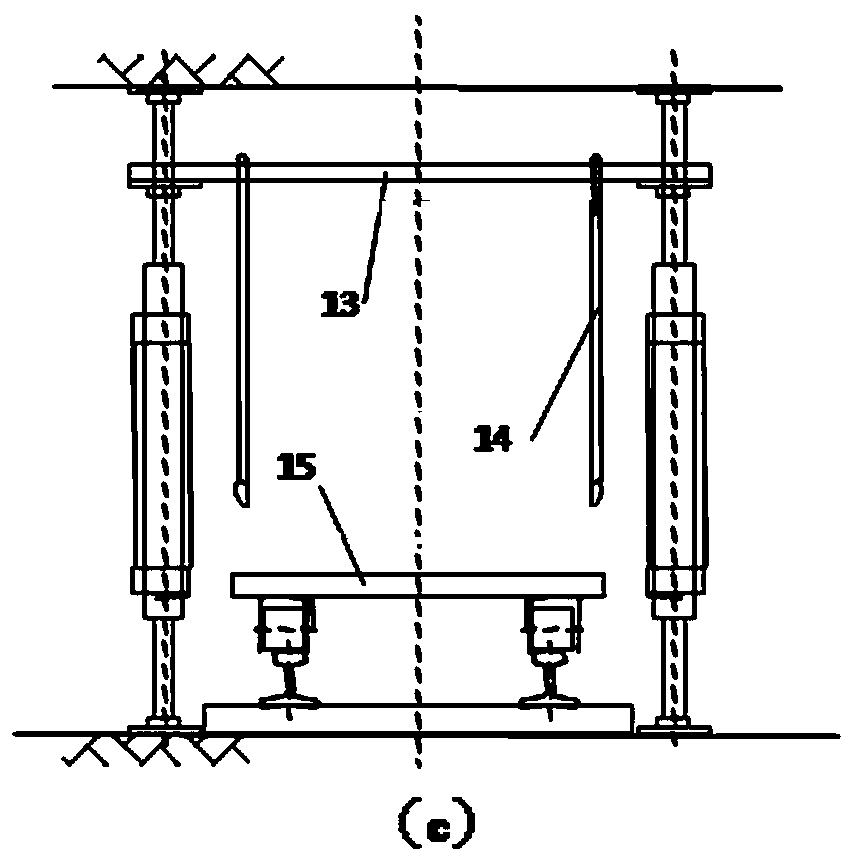

[0035] Such as figure 1 As shown, a rail-type car loading machine includes a fixed frame 1, and the fixed frame 1 is divided into two symmetrical parts, a left fixed frame and a right fixed frame, and a preset is respectively arranged at both ends of the left and right fixed frames Reserving holes, two reserved holes are arranged in the middle of the left and right fixing frames; the two ends of the left and right fixing frames are respectively fixedly connected with telescopic supporting columns 2 through the reserved holes at both ends, and the left and right fixing frames pass through the middle The two reserved holes are connected with two telescopic lifting columns 3, the supporting columns 2 connected by the left and right fixed frames are arranged symmetrically, and the lifting columns 3 connected by the left and right fixed frames are arranged symmetrically; The upper and lower ends of the right fixed frame are connected by two upper connecting beams 11 and two lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com