High-toughness aluminum sheet strip for new energy automobile and production method of high-toughness aluminum sheet strip

A technology for a new energy vehicle and a production method, applied in the field of high toughness aluminum sheet and strip for new energy vehicles and its production, can solve the problems of poor strength, impact resistance and toughness, easy cracking, deformation, etc., and achieve stable product performance, Strong dent resistance and uniform chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

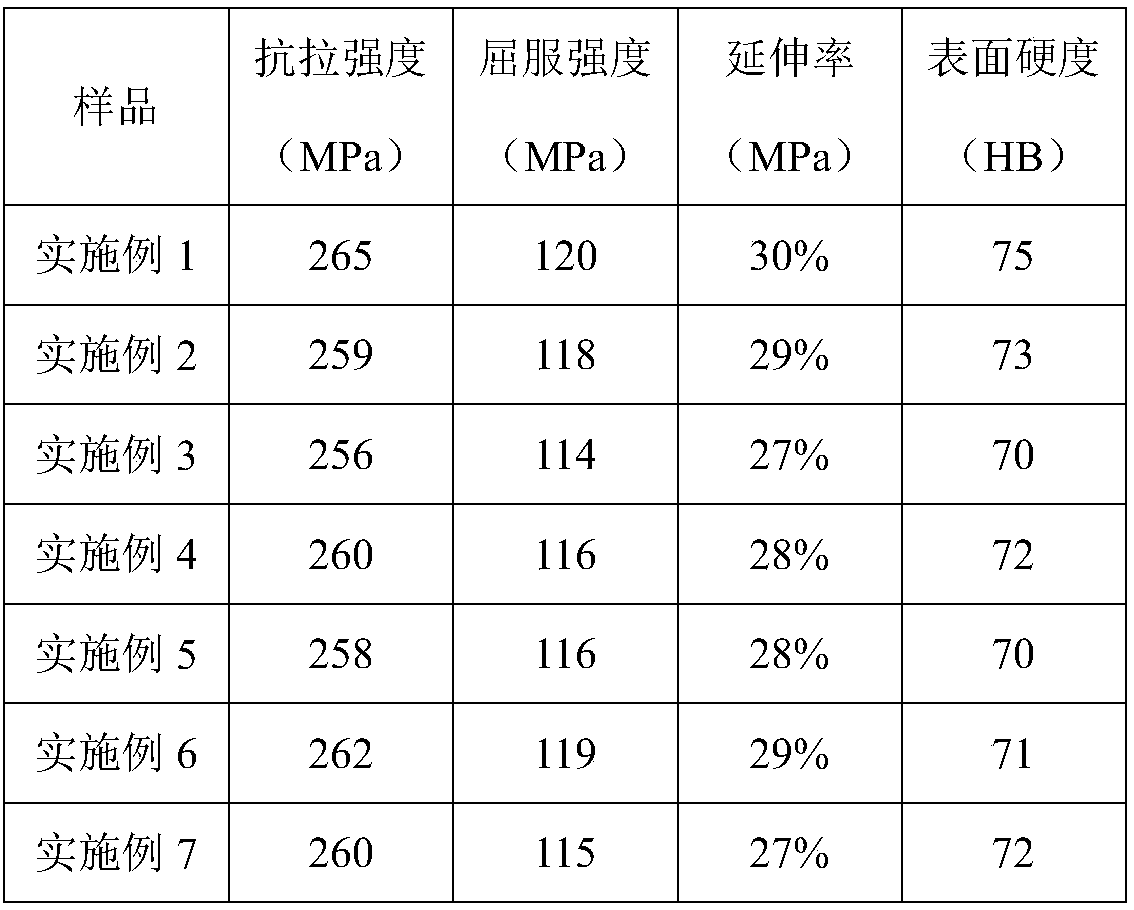

Examples

Embodiment 1

[0030] A high-toughness aluminum sheet and strip for new energy vehicles, expressed in mass percentage, its composition is: Si0.05%, Fe 0.10%, Cu 0.01%, Mn 0.48%, Mg 4.2%, Cr 0.012%, La 0.003%, Ce 0.004%, Ti 0.014%, and the balance is Al.

Embodiment 2

[0032] A high-toughness aluminum sheet and strip for new energy vehicles, expressed in mass percentage, its composition is: Si0.06%, Fe 0.08%, Cu 0.015%, Mn 0.46%, Mg 4.15%, Cr 0.01%, La 0.004%, Ce 0.005%, Ti 0.016%, and the balance is Al.

Embodiment 3

[0034] A high-toughness aluminum sheet and strip for new energy vehicles, expressed in mass percentage, its composition is: Si0.01%, Fe 0.06%, Cu 0.02%, Mn 0.5%, Mg 4.1%, Cr 0.02%, La 0.002%, Ce 0.002%, Ti 0.018%, and the balance is Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com