Method for preparing vanadium electrolyte

A technology of electrolyte and solution, which is applied in the field of preparation of vanadium electrolyte, can solve the problems of complicated steps, high preparation cost, and poor controllability, and achieve the effect of low cost, few steps, and strong controllability of composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

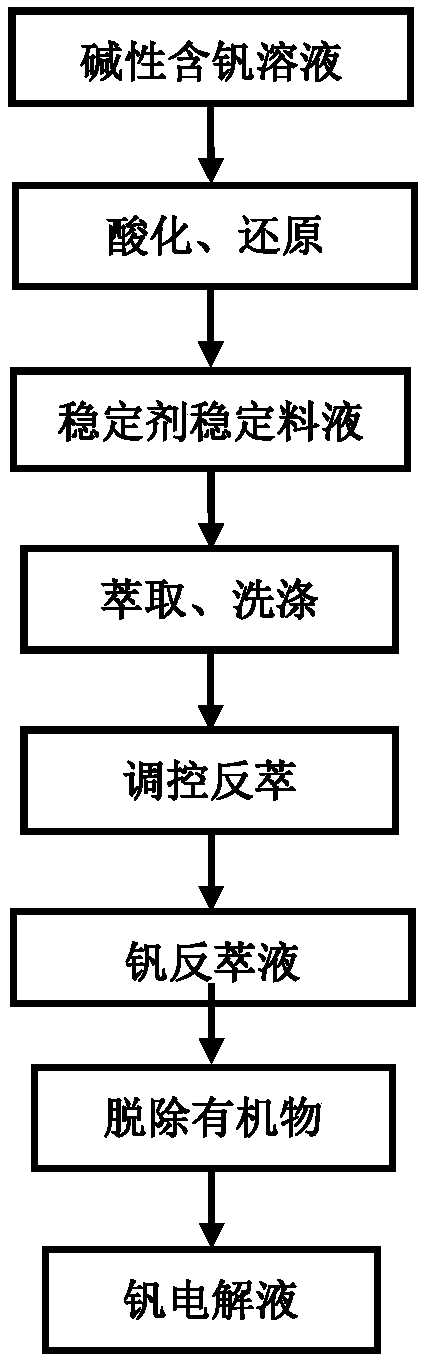

Method used

Image

Examples

Embodiment 1

[0041] Dissolve the vanadium raw material in sodium hydroxide alkali solution to obtain an alkaline solution containing vanadium ~ 20g / L. The alkaline vanadium-containing solution contains impurities (g / L): Si 0.74; Al 0.36; Ca 0.039; Mn 0.017; Cu 0.012; Na 39.7, Fe and other impurities are less than 10mg / L.

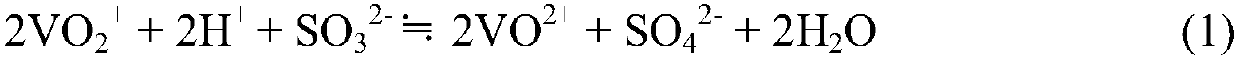

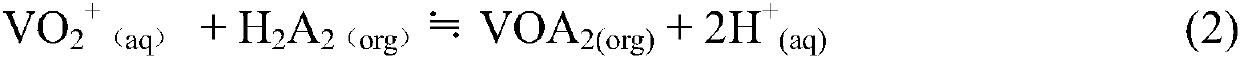

[0042] Add sulfuric acid to the basic vanadium-containing solution to adjust the pH to 3.0, and then add sodium sulfite heptahydrate as a reducing agent. The amount of sodium sulfite is 1.1 times the theoretical content, and the vanadium is completely reduced to tetravalent. The solution after reduction was added with 0.1% hexamethylphosphoramide as a stabilizer, and then extracted with 30% (v / v) P507 / kerosene, compared to (organic phase / water phase volume ratio) 1:1, the three levels of vanadium at room temperature Stage countercurrent stage extraction, control the equilibrium pH to 1.8, and the extraction rate is 99%. The organic phase after extraction was mixed with ...

Embodiment 2

[0044] The basic vanadium-containing solution in Example 1 is adjusted to a pH value of 0.2 with hydrochloric acid, and then added H 2 o 2 reduction, H 2 o 2 The consumption is 2 times of theoretical consumption, and the feed liquid after reduction, adds 1% phenylphosphoric acid, adopts 40% (v / v) P204 / heptane extraction again, adopts five-stage countercurrent extraction, compares (organic phase / water Phase volume ratio) 5: 1, the five-stage extraction of vanadium, the control equilibrium pH is 1.5, and the extraction rate is 99.8%. The extracted organic phase was washed with 0.02M H2O containing 5g / L V(IV). 2 SO 4 The solution was subjected to five-stage countercurrent washing at room temperature, and the washing ratio (volume ratio of organic phase / water phase) was 5:1. After washing with 4.5mol / L H 2 SO 4 Carry out five-stage countercurrent stripping of vanadium under the condition of 20:1 with the ratio (organic phase / water phase volume ratio) at room temperature, t...

Embodiment 3

[0046] The basic vanadium-containing solution in Example 1 was adjusted to pH 1.5 with sulfuric acid, then added oxalic acid for reduction, then added 0.5% methylphosphoric acid as a silicon stabilizer, extracted with 5% (v / v) Cyannex272 / tridecane, The extraction ratio (volume ratio of organic phase / water phase) is 1:5, at room temperature, the equilibrium pH is controlled to be 1.5, and the single-stage extraction rate of vanadium is 85%. The organic phase after extraction was mixed with 0.05mol / L H containing 2g / L V 2 SO 4 The solution was washed at room temperature with a wash ratio (volume of organic phase:volume of aqueous phase) of 10:1. After washing with 5.0mol / L H 2 SO 4 Carry out single-stage stripping vanadium under the condition of being 1: 1 at room temperature, the stripping rate of vanadium is 95.7%, and the content of stripping liquid contains 1.59mol / L V and 2.9mol / L H 2 SO 4 , the total content of impurities (including Si, Al, Fe, Mg, Ca) is less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com