Ramaria botrytoides refined polysaccharide as well as preparation method and application thereof

A technology of coral bacteria and polysaccharides, applied in the field of medicine, to achieve the effect of enhanced release and increased expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

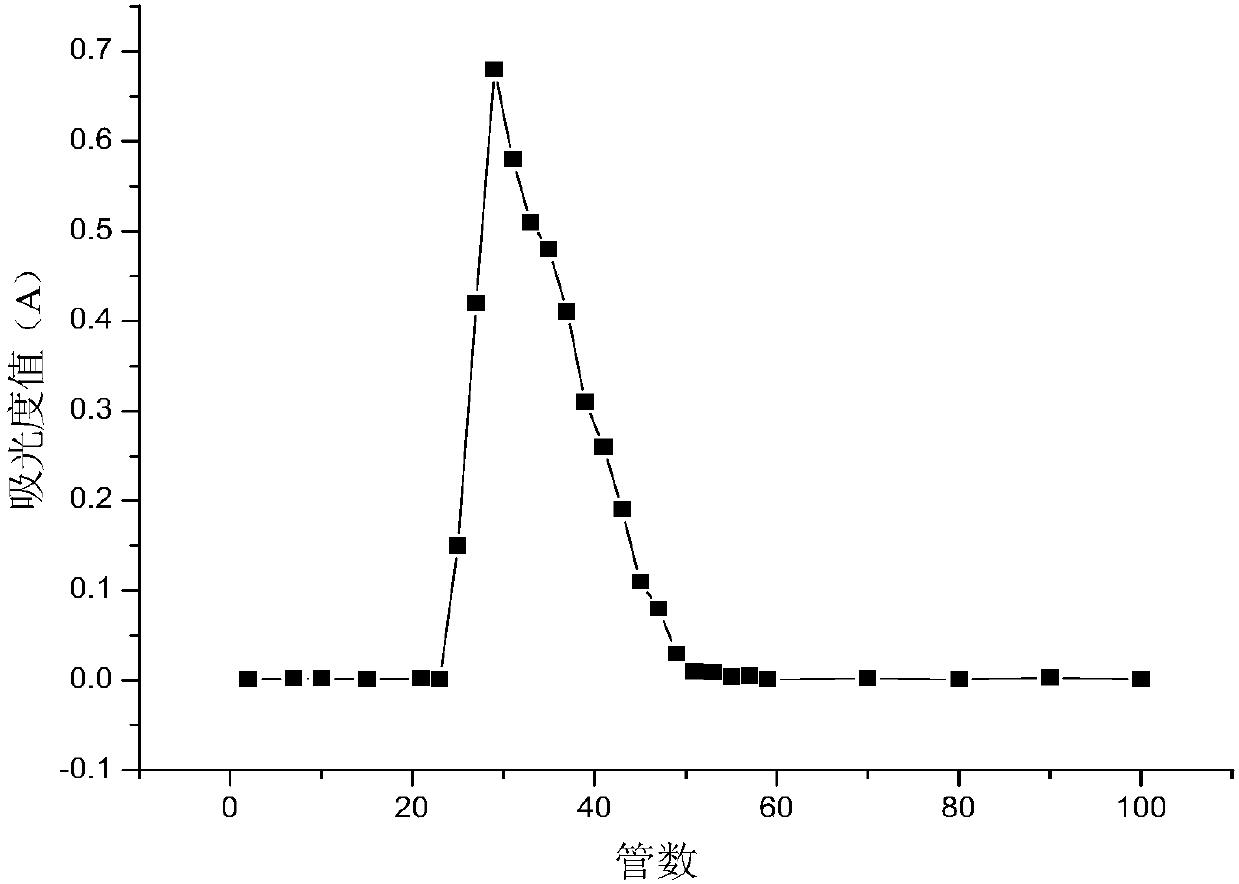

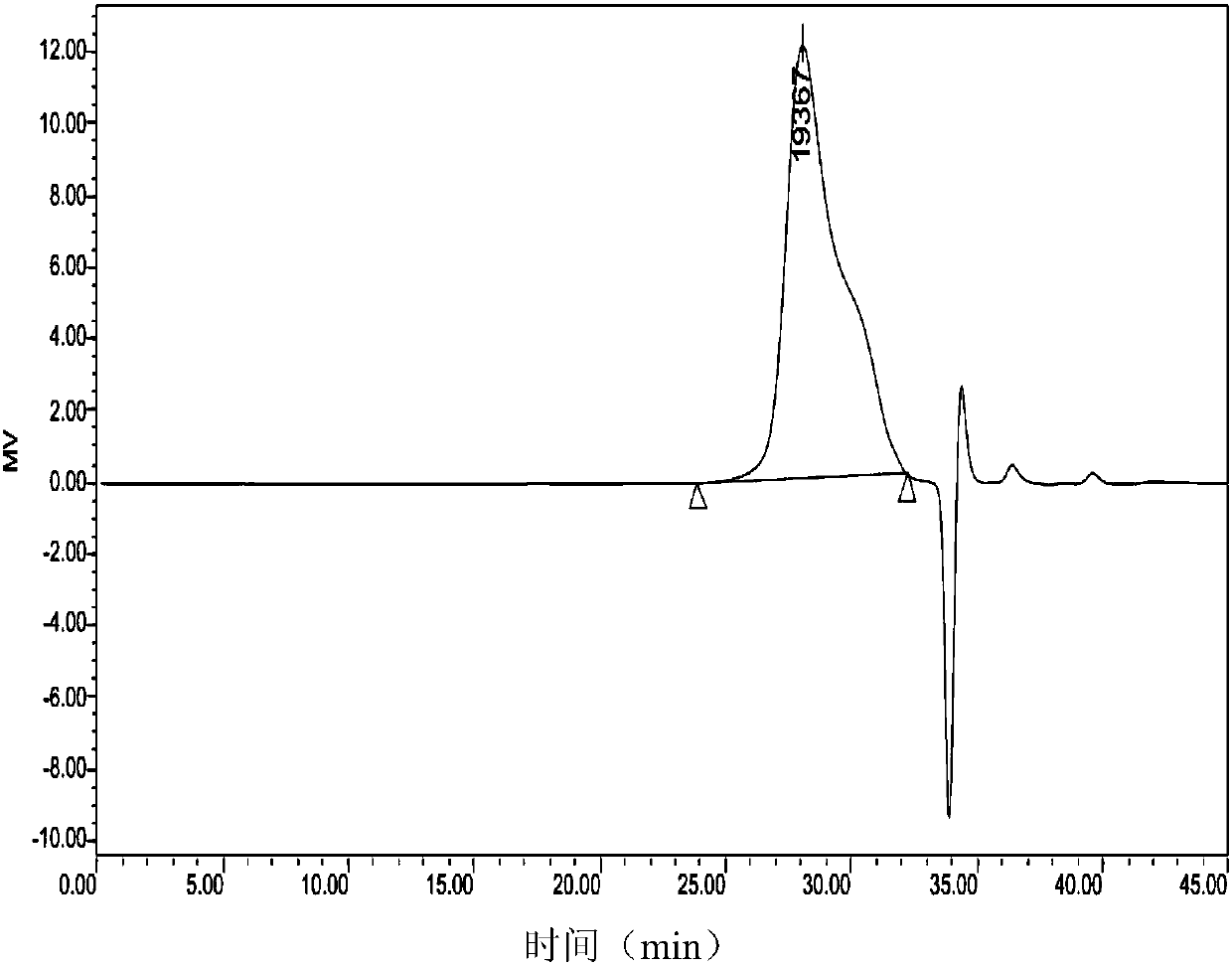

[0054] Example 1 Preparation of Coral Fungus Crude Polysaccharides (RBPs) from Coral Fungus:

[0055] (1) After crushing the coral bacteria, pass through a 20-mesh sieve, weigh 100g, heat reflux with distilled water for extraction, wherein the water to material ratio is 30:1 (mass ratio), the reflux extraction temperature is 90℃, the reflux extraction time is 1h, reflux Extraction times 3 times; then combine the extracts, centrifuge at 4000r / min for 10min, take the supernatant liquid, filter 3 times with filter paper, and concentrate the filtrate with a rotary evaporator at 40°C under reduced pressure to 200mL to obtain a polysaccharide solution;

[0056] (2) D354FD resin was soaked in distilled water for 12 hours, and then immersed in 5% by mass hydrochloric acid solution and 5% by mass sodium hydroxide solution respectively for 0.5h, filtered with 200 mesh gauze, and washed with distilled water until it became neutral. Obtain pretreated D354FD resin;

[0057] (3) Mix the polysacch...

Embodiment 2

[0059] Example 2 Preparation of Coral Fungus Crude Polysaccharides (RBPs) from Coral Fungus:

[0060] (1) The coral bacteria are crushed and passed through a 20-mesh sieve, weighed 100g, and then heated and refluxed for extraction with distilled water. The ratio of water to material is 30:1 (mass ratio), the reflux extraction temperature is 90℃, reflux extraction time is 1h, reflux extraction The number of times is 2; then the extracts are combined, centrifuged at 3000r / min for 8min, the supernatant liquid is taken, and the filter paper is filtered twice. The filtrate is concentrated to 200mL under reduced pressure with a rotary evaporator at 50°C to obtain a polysaccharide solution;

[0061] (2) D354FD resin was soaked in distilled water for 24 hours, and then immersed in 5% by mass hydrochloric acid solution and 5% by mass sodium hydroxide solution for 2 hours respectively, filtered with 200 mesh gauze, and washed with distilled water until it became neutral. D354FD resin after p...

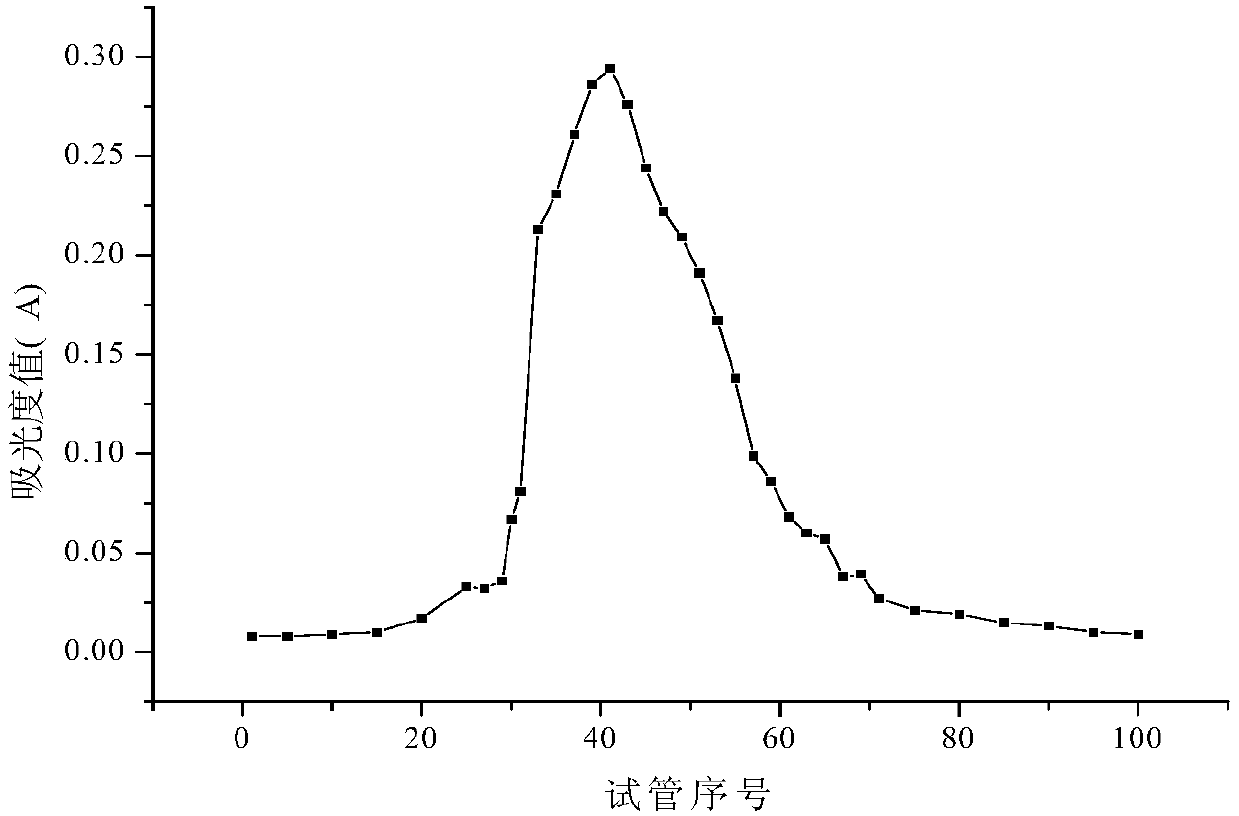

Embodiment 3

[0064] Example 3 Preparation of Coral Fungus Crude Polysaccharides (RBPs) from Coral Fungus:

[0065] (1) After crushing the coral bacteria, pass through a 20-mesh sieve, weigh 100g, and heat and reflux with distilled water for extraction. The ratio of water to material is 30:1 (mass ratio), the reflux extraction temperature is 95°C, the reflux extraction time is 2h, reflux Extract 4 times, then combine the extracts, centrifuge at 5000 / min for 12 min, take the supernatant liquid, filter 4 times with filter paper, and concentrate the filtrate to 200 mL under reduced pressure with a rotary evaporator at 60°C to obtain a polysaccharide solution;

[0066] (2) D354FD resin was soaked in distilled water for 18 hours, and then immersed in 5% by mass hydrochloric acid solution and 5% by mass sodium hydroxide solution respectively for 3 hours, filtered with 200 mesh gauze, and washed with distilled water to neutrality. D354FD resin after pretreatment;

[0067] (3) Mix the polysaccharide solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com