Process method for producing ethylene glycol mono-tert-butyl ether

A technology of mono-tert-butyl ether and process method, applied in the field of chemical product production technology, can solve problems such as low content of ethylene glycol mono-tert-butyl ether, and achieve the effect of improving market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of processing method of producing ethylene glycol mono-tert-butyl ether, this processing method is realized by following device:

[0028] The used device for producing ethylene glycol mono-tert-butyl ether, the 1-ethylene glycol mono-tert-butyl ether refining tower feed pump is connected to the lower part of the 2-ethylene glycol mono-tert-butyl ether refining tower through pipeline a, 2- The top of the ethylene glycol mono-tert-butyl ether refining tower is connected to the circulation tank of the 7-ethylene glycol mono-tert-butyl ether refining tower through pipeline b, and the top of the 7-ethylene glycol mono-tert-butyl ether refining tower circulation tank is passed through the pipeline c is connected with 2-ethylene glycol mono-tert-butyl ether refining tower; the bottom of 2-ethylene glycol mono-tert-butyl ether refining tower is connected with the lower part by pipeline d; described 2-ethylene glycol mono-tert-butyl ether The bottom of the refining tower ...

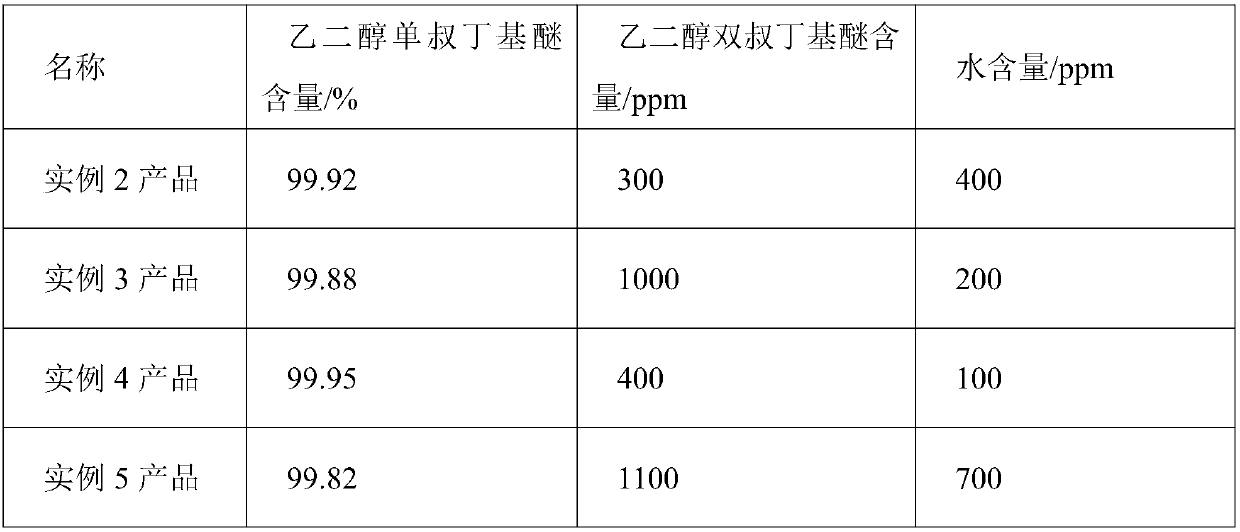

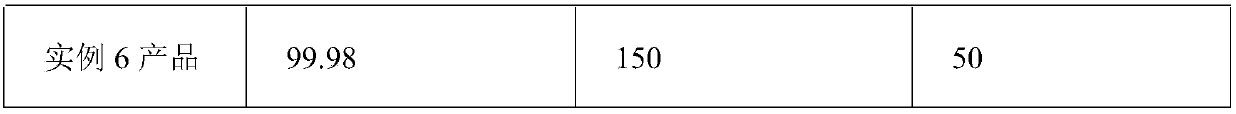

Embodiment 2

[0031]The ordinary ethylene glycol mono-tert-butyl ether product with ethylene glycol mono-tert-butyl ether content of 98.5%, ethylene glycol bis-tert-butyl ether content of 0.6%, and water content of 0.9% is used as rectification raw material, and isoamyl acetate As an entrainer, it is sent to the ethylene glycol refining tower for azeotropic distillation; the amount of isoamyl acetate added is twice the total mass of ethylene glycol bis-tert-butyl ether and water, and the rectifying pressure is normal pressure , the extraction temperature at the top of the tower is 85-87°C, and the temperature of the tower bottom is 120-122°C, the heavy components are extracted from the bottom of the ethylene glycol mono-tert-butyl ether refining tower, and after being condensed by the condenser to 40°C, the Airspeed 2.0h -1 Remove the remaining trace water through the ethylene glycol mono-tert-butyl ether purifier equipped with 5A molecular sieves to obtain high-quality ethylene glycol mono...

Embodiment 3

[0033] The ordinary ethylene glycol mono-tert-butyl ether product with ethylene glycol mono-tert-butyl ether content of 98.5%, ethylene glycol bis-tert-butyl ether content of 0.6%, and water content of 0.9% is used as the rectification raw material, and isoamyl alcohol is used as the The entrainer is sent to the ethylene glycol refining tower for azeotropic distillation; the addition of isoamyl alcohol is twice the total mass of ethylene glycol di-tert-butyl ether and water, and the rectifying pressure is normal pressure. Under the condition that the top extraction temperature is 92-95°C and the tower tank temperature is 123-125°C, the heavy components are extracted from the bottom of the ethylene glycol mono-tert-butyl ether refining tower, and after being condensed by the condenser to 40°C, the 2.0h -1 Remove the remaining trace water through the ethylene glycol mono-tert-butyl ether purifier equipped with 5A molecular sieves to obtain high-quality ethylene glycol mono-tert-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com