Alumina decomposition tank stirring system

A technology of a stirring system and a decomposition tank, which is applied in the field of dynamic stirring systems, can solve the problems of high maintenance and repair costs, high costs, and reduced reaction efficiency, and achieves the effects of low maintenance and maintenance costs, low manufacturing costs, and small effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained in detail below with reference to the drawings and specific embodiments of the specification. It is worth noting that the following specific embodiments are only used to illustrate the technical solutions of the present invention, rather than limiting, and are based on the spirit of the technical solutions of the present invention. Modification or equivalent replacement of the technical solution of the invention belongs to the protection scope of this patent right.

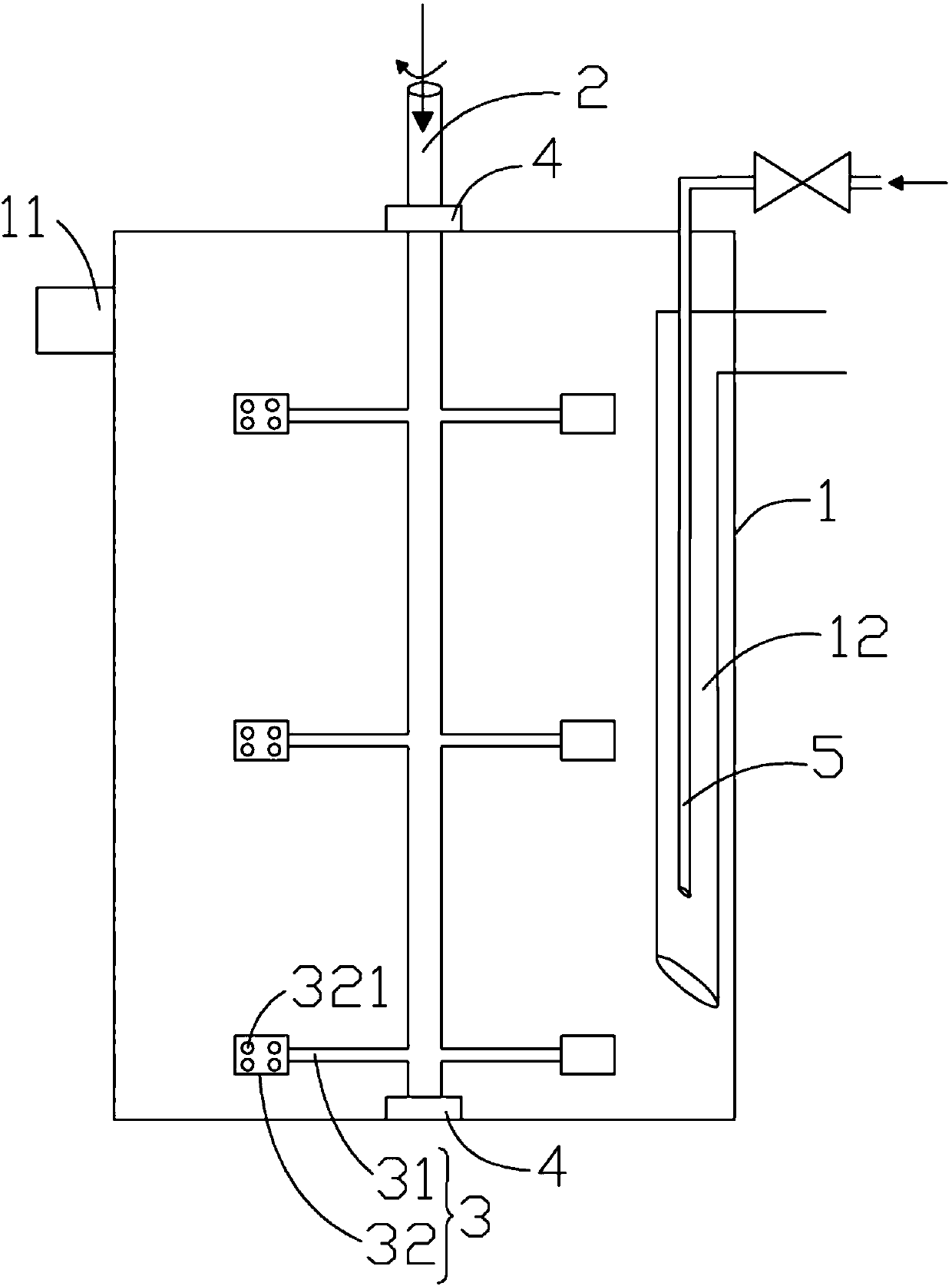

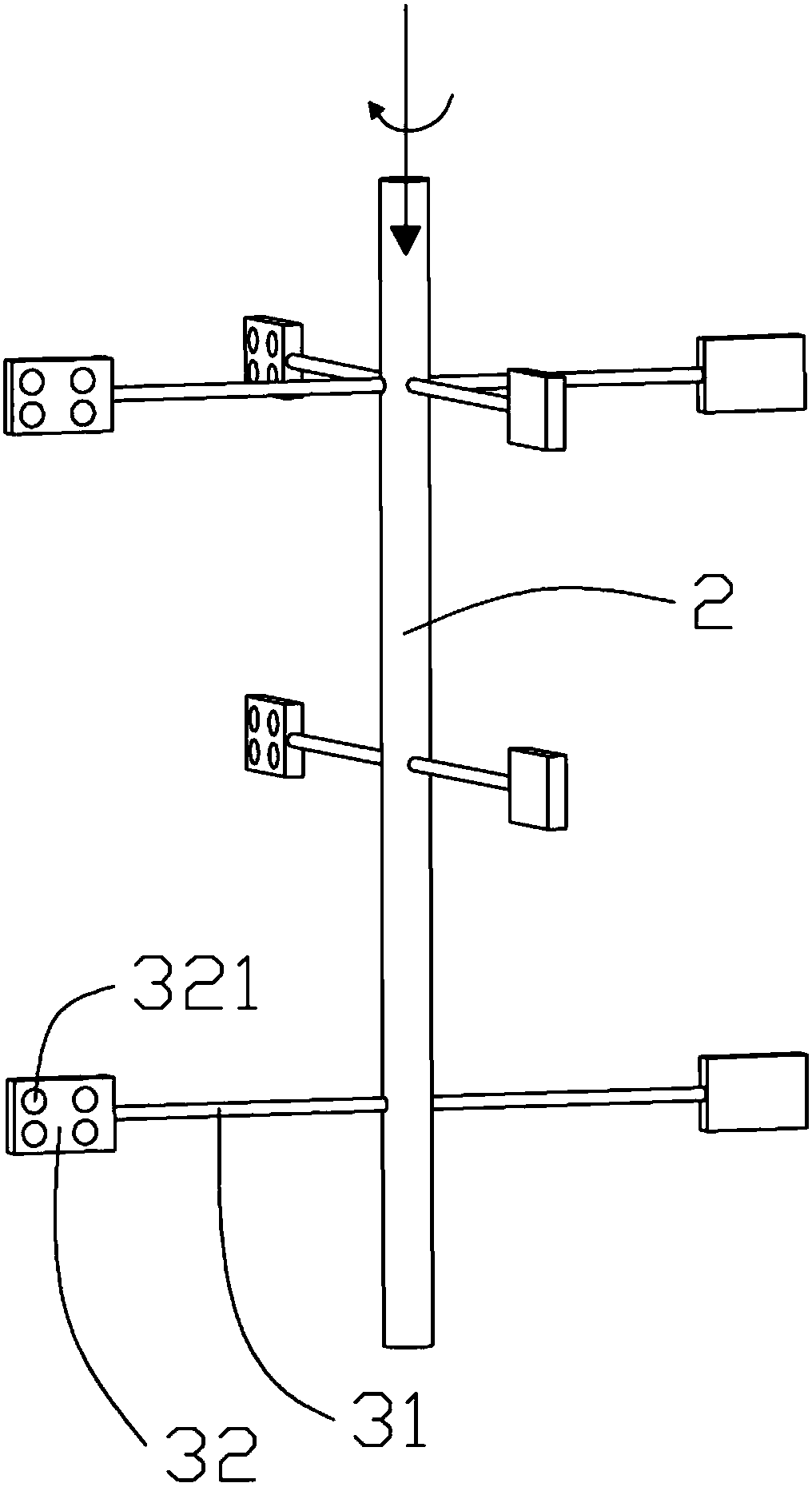

[0022] Such as figure 1 -2. An alumina decomposition tank stirring system, comprising a tank body 1 and a wind stirring device; the tank body 1 is a cylindrical structure, and the wind stirring device is used to stir the slurry inside the tank body 1; the tank body 1. A feeding pipe 11 is opened on the side of the tank 1 to feed the slurry into the cavity of the tank 1; from the upper side of the tank 1 a feeding pipe 12 extends directly to the bottom of the tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com