Extruding machine

A technology of extruder and extrusion screw, which is applied in the field of food processing mechanisms, can solve the problems of troublesome replacement or disassembly of transmission gears, and achieve the effects of improving efficiency, reducing eccentric force, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

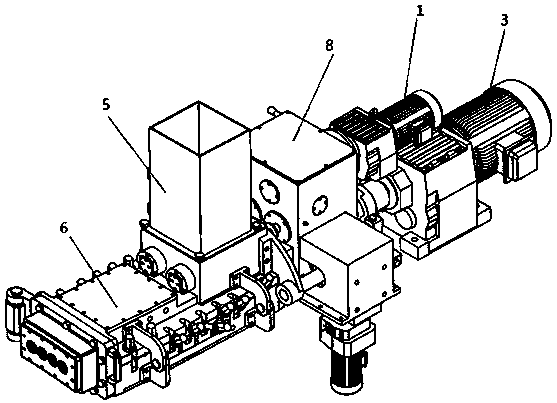

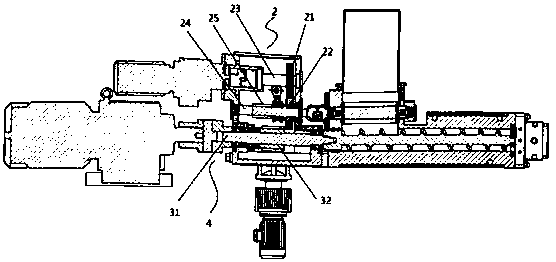

[0017] Such as Figure 1 to Figure 3 A kind of extruder shown, comprises feeding driving motor 1, feeding transmission system 2, extruding screw driving motor 3, extruding transmission system 4, feeding cabin 5 and extrusion cabin 6; Said feeding driving motor 1 and feeding The transmission system 2 is connected through a reducer, and the output end of the feeding transmission system 2 is connected to the feeding cabin 5; the extrusion screw driving motor 3 is connected with the extrusion transmission system 4 through a reduction box, and the output end of the extrusion transmission system 4 is connected to the Extrusion boxes 6 are connected.

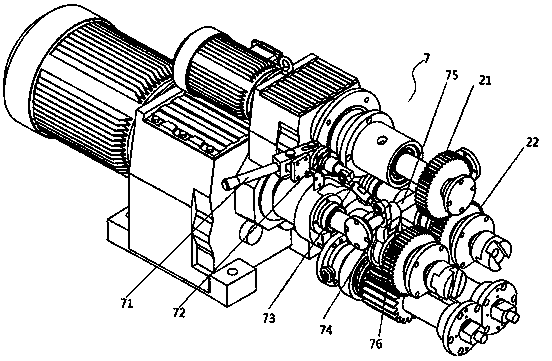

[0018] The feeding transmission system 2 includes a main transmission gear 21, a driven gear 22, a driving shaft 23 and a driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com