Positioning device and method for hydrophobicity detection of composite insulator based on unmanned aerial vehicle

A technology of composite insulators and positioning devices, which is applied in the directions of measuring devices, launching devices, three-dimensional position/channel control, etc., and can solve problems such as difficult to accurately control water spray heads and composite insulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

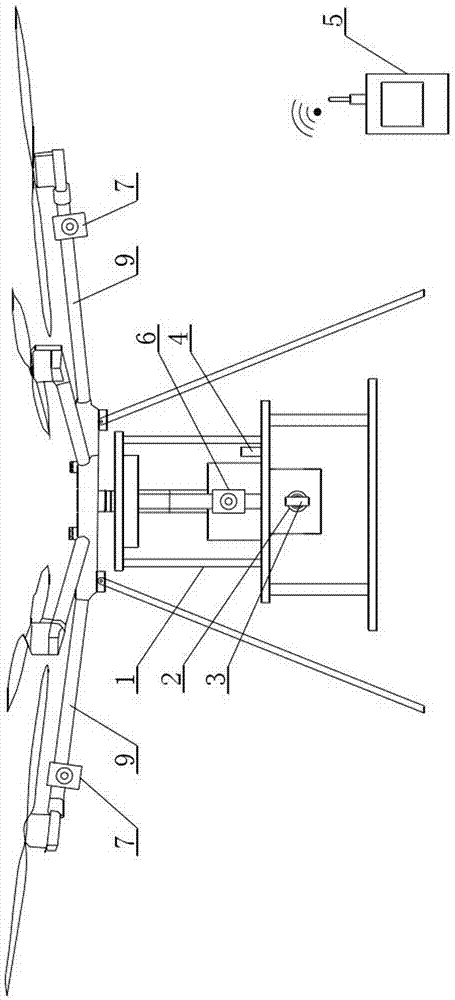

[0052] like figure 1 , figure 2 and image 3 As shown, the positioning device based on the UAV-based composite insulator hydrophobicity detection includes a multi-rotor UAV body 1, and a water spray insulation rod 2 arranged at the bottom of the multi-rotor UAV body 1 is arranged on the nozzle. The water spray head 3 at the front end of the water insulating rod 2, the positioning module arranged on the multi-rotor UAV body 1, the image acquisition module 4 arranged on the multi-rotor UAV body 1, and the An image monitoring module 5 controlled by an operator;

[0053] The positioning module includes a first positioning laser transmitter 6 and two second positioning laser transmitters 7, the first positioning laser transmitter 6 is installed on the front side of the multi-rotor UAV body 1 and is located in the Directly above the water spray insulation rod 2, the first positioning laser transmitter 6 is used for rough positioning, and the laser beam emitted by the first posit...

Embodiment 2

[0067] The difference from Embodiment 1 is that the image acquisition module 4 includes an image acquisition camera and an image return transmitter.

[0068] The image monitoring module 5 includes an image return receiver and an image monitor, the image return receiver is used to receive the image signal sent by the image return transmitter, and the image monitor is used to display the image return The image signal received by the receiver.

[0069] The water spray head is made of aluminum alloy, and the aluminum alloy is made of the following components in mass percentage:

[0070] Mg: 2.8%;

[0071] Si: 4.2%;

[0072] Mn: 0.28%;

[0073] Cr: 0.16%;

[0074] Zr: 0.23%;

[0075] Ti: 0.38%;

[0076] Yb: 0.25%;

[0077] The balance is Al and impurities with a content of ≤0.05%.

[0078] In this embodiment, the image monitor is an LCD monitor, and it is obvious that an LED monitor can have the same effect.

[0079] In this embodiment, the image acquisition module include...

Embodiment 3

[0081] It differs from Embodiment 2 in that: the image monitor is an LCD monitor.

[0082] The water spray head is made of aluminum alloy, and the aluminum alloy is made of the following components in mass percentage:

[0083] Mg: 2.2%;

[0084] Si: 3.6%;

[0085] Mn: 0.23%;

[0086] Cr: 0.12%;

[0087] Zr: 0.20%;

[0088] Ti: 0.36%;

[0089] Yb: 0.18%;

[0090] The balance is Al and impurities with a content of ≤0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com