Testing clamp for spring products

A technology of product testing and fixtures, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as difficult replacement, production waste, and impact of jaws, and achieve the effects of avoiding displacement and deformation, improving detection efficiency, and stabilizing the grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

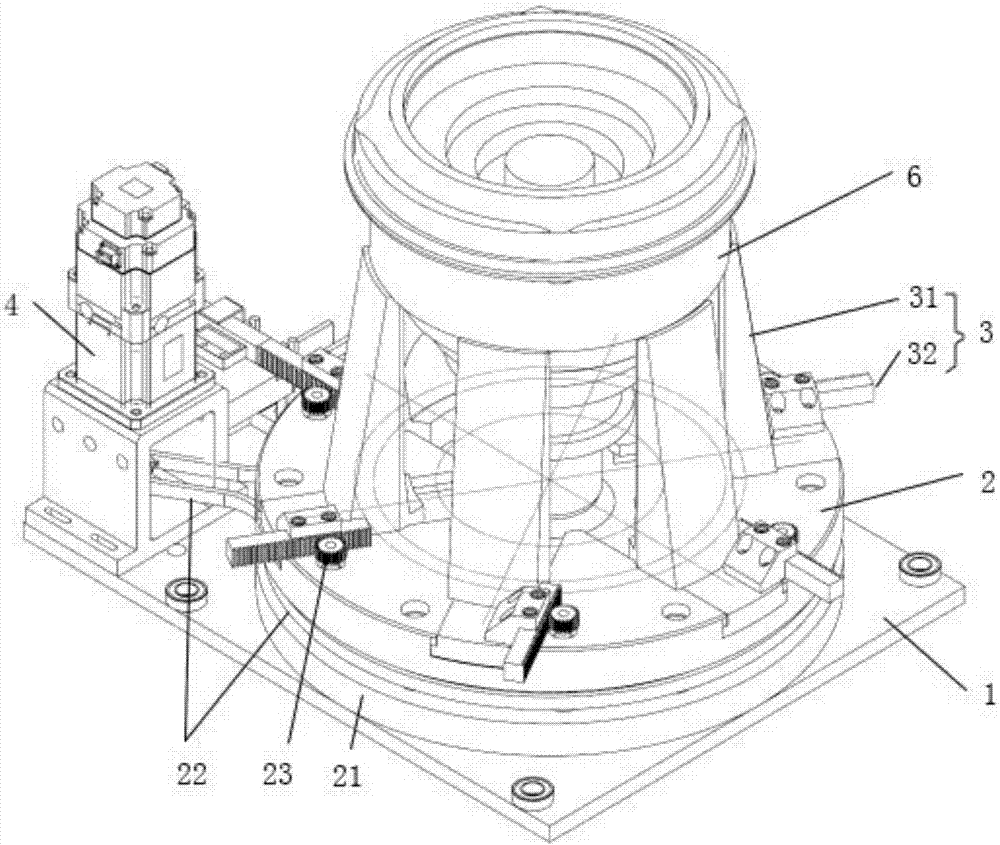

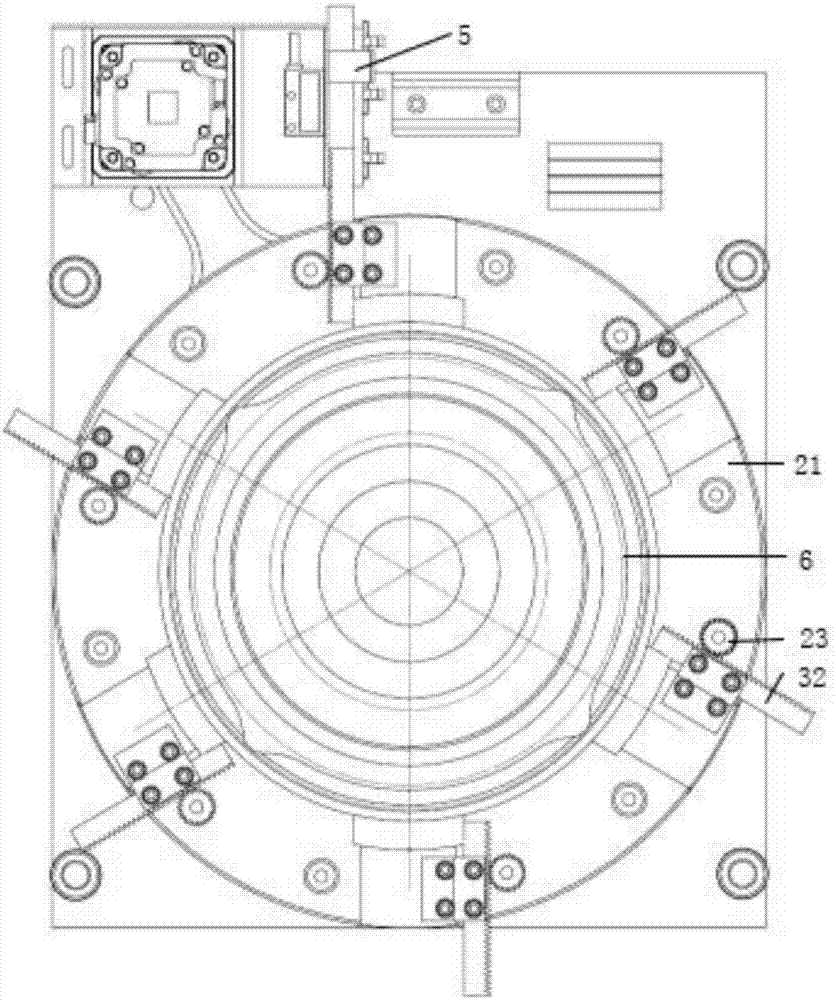

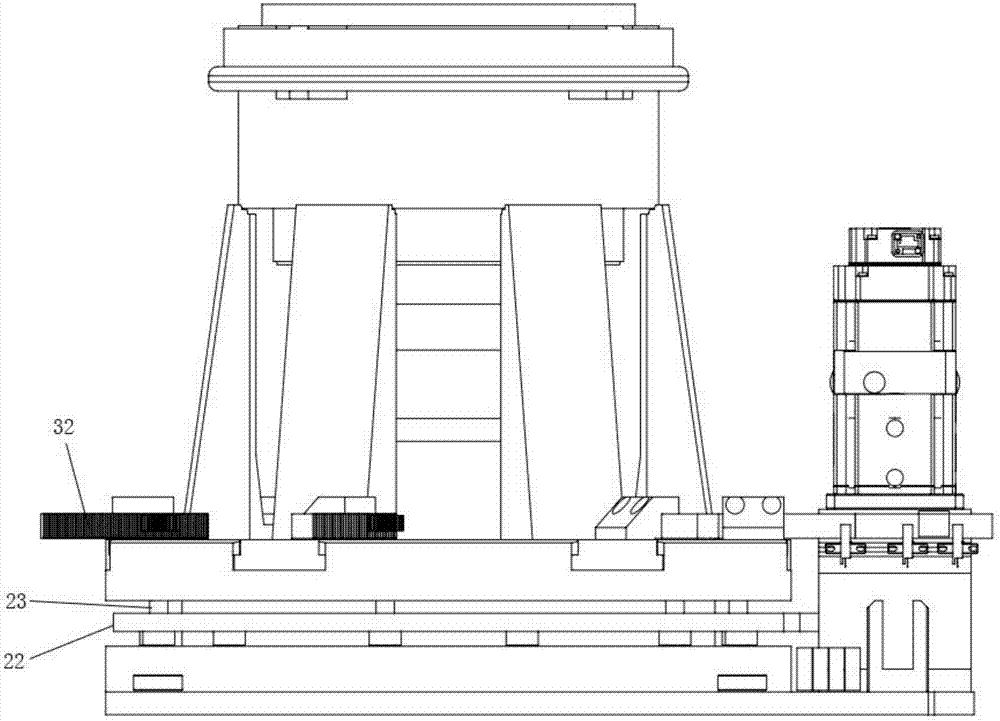

[0026] refer to figure 1 and image 3 As shown, the present invention provides a test fixture for spring products, including: a base surface 1, a transmission mechanism 2, a synchronous jaw 3 and a servo motor 4; the servo motor 4 and the transmission mechanism 2 are respectively arranged on the base surface 1; The synchronous jaw 3 is arranged on the transmission mechanism 2 and includes several claw petals 31. The claw petals 31 are distributed around the upper surface of the transmission mechanism 2 and can slide on the upper surface of the transmission mechanism 2; the servo motor 4 and The transmission mechanism 2 is connected, and the servo motor 4 drives the transmission mechanism 2 to move, thereby driving the claw valve 31 to move synchronously from the periphery of the transmission mechanism 2 to the axis of the transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com