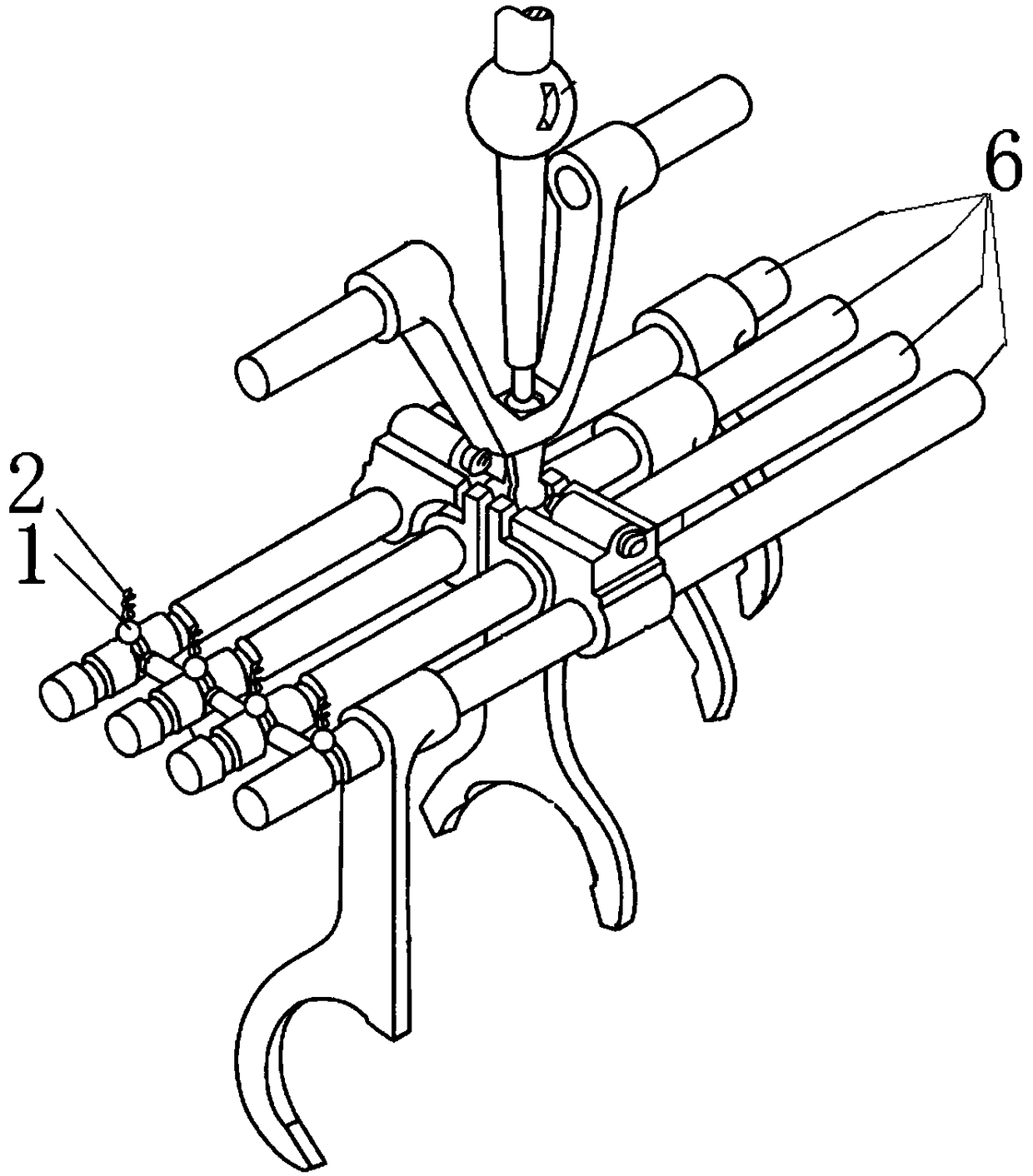

Transmission, transmission actuating mechanism and positioning locking device for shift fork shaft

A control mechanism and shifting fork shaft technology, applied in mechanical control devices, transmission control, instruments, etc., can solve problems such as damage to the transmission, a large number of parts, increase the difficulty of layout and cost, and reduce the number of parts and reduce costs. The effect of layout difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0035] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

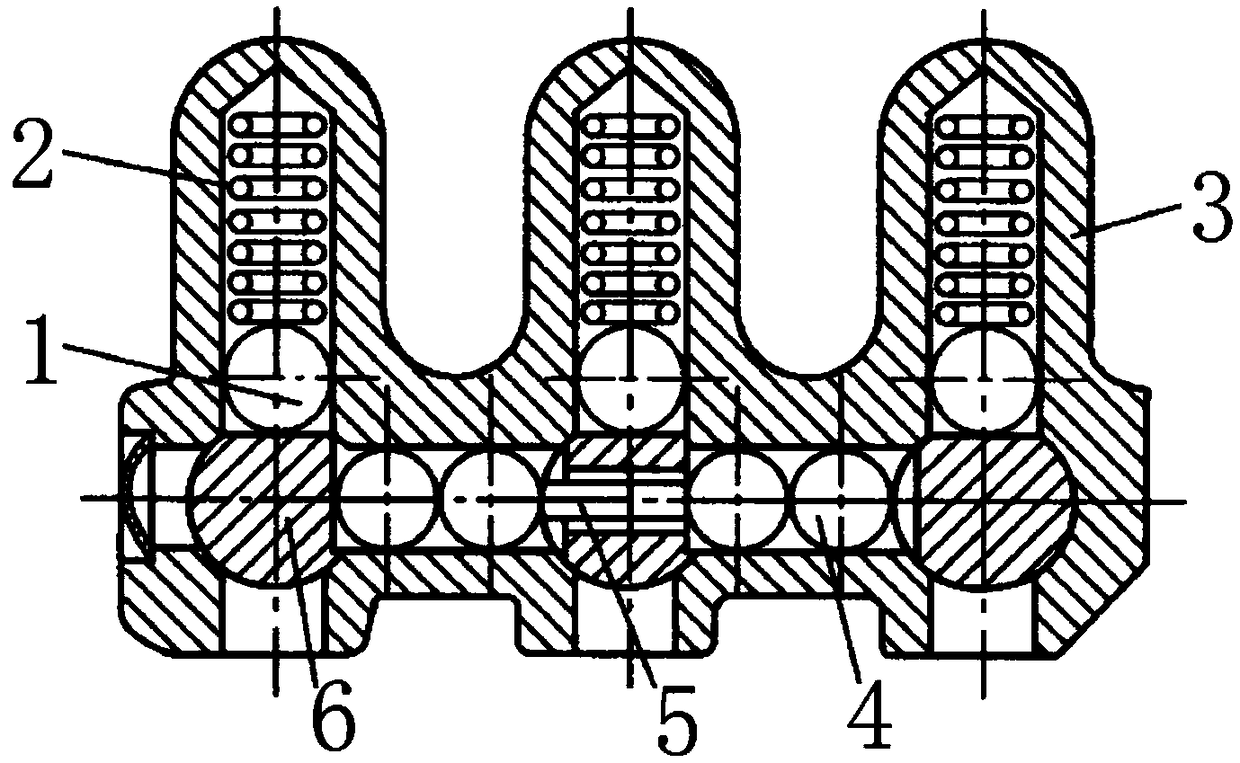

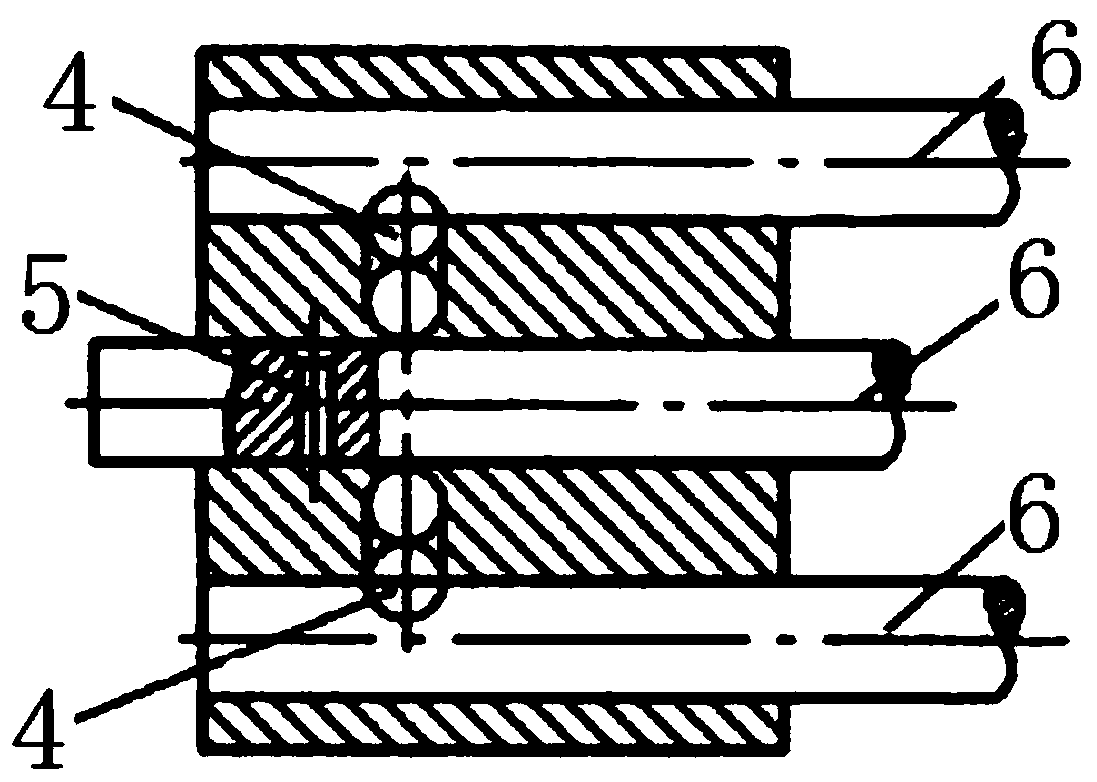

[0036] refer to Figure 4 and Figure 5 As shown, according to a preferred embodiment of the positioning and locking device for the fork shaft of the present invention, the self-locking and / or interlocking of the fork shaft 6 can be realized. The positioning locking device includes a torsion spring 7 and a pair of interlocking discs 8 . Wherein, the pair of interlocking discs 8 are matched with each other, and have a tendency to rotate relative to each other under the action of the torsion spring 7 . For example, combining 6A to 6D As shown, between the first interlocking disc 8a and the second interlocking disc 8b 6A to 6D During the relative rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com