Multiple-in and multiple-out type pressure exchanger

A pressure exchanger, multi-in and multi-out technology, applied in the direction of machine/engine, osmotic/dialysis water/sewage treatment, seawater treatment, etc., can solve the problems of high price, small processing capacity of a single machine, high processing difficulty, and reduce processing. Difficulty, easy to install, fix and replace, the effect of stable rotor operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

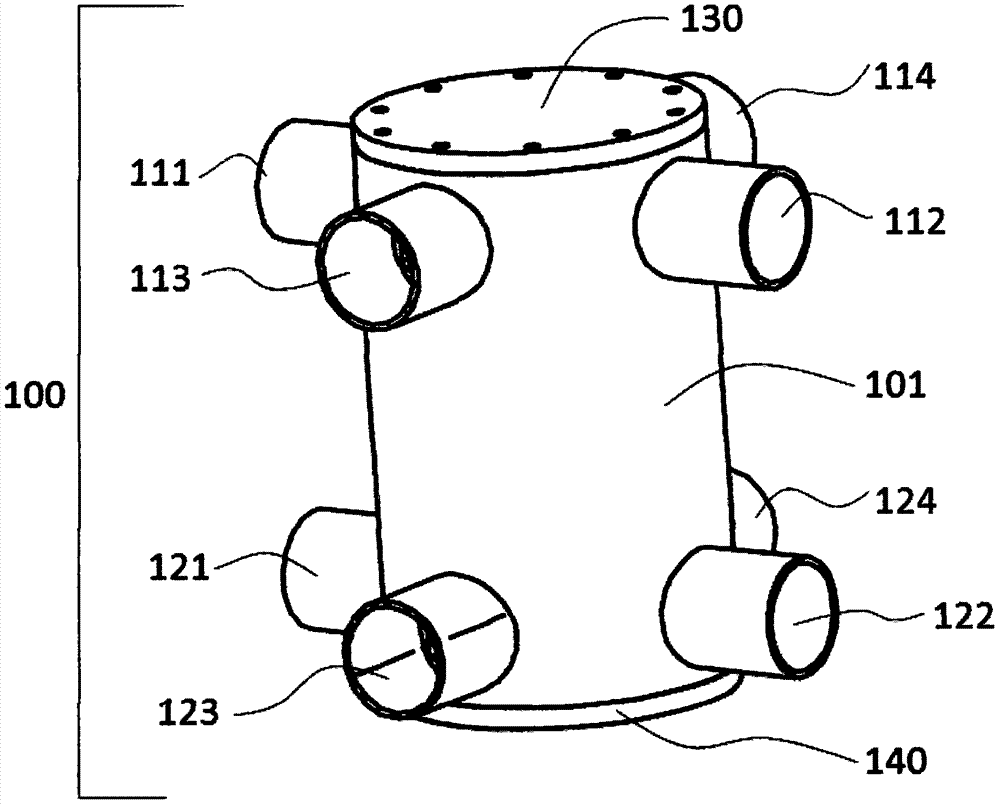

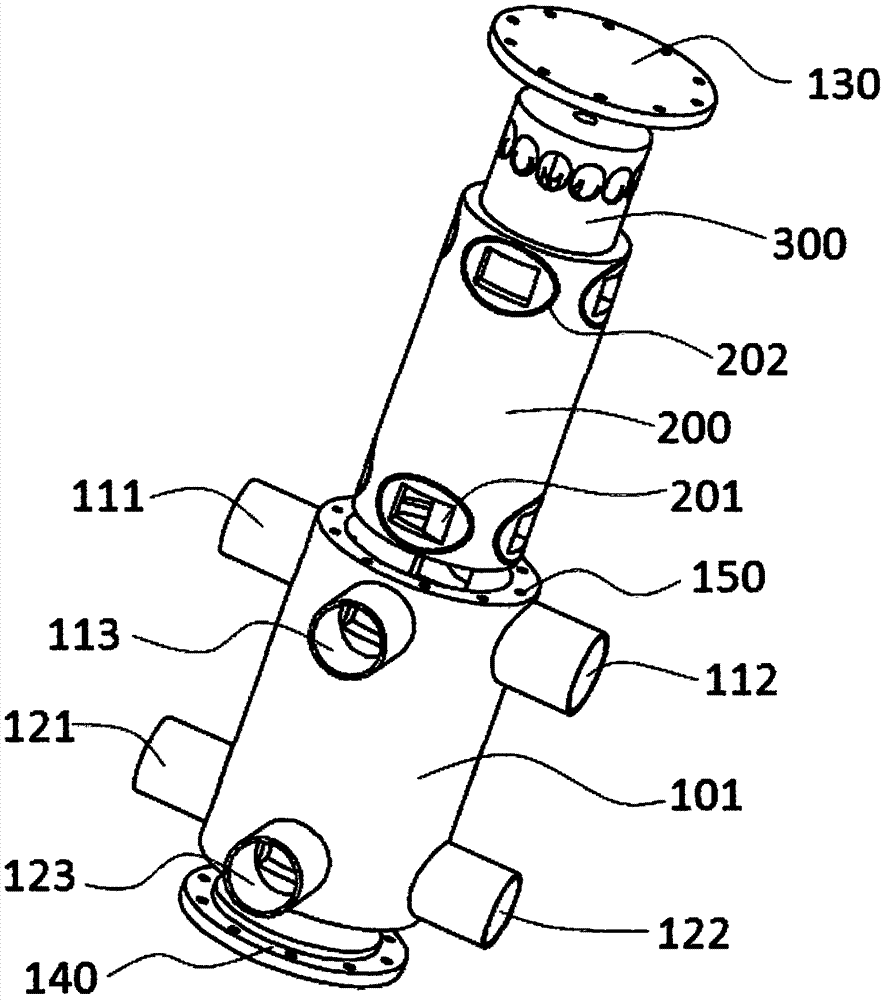

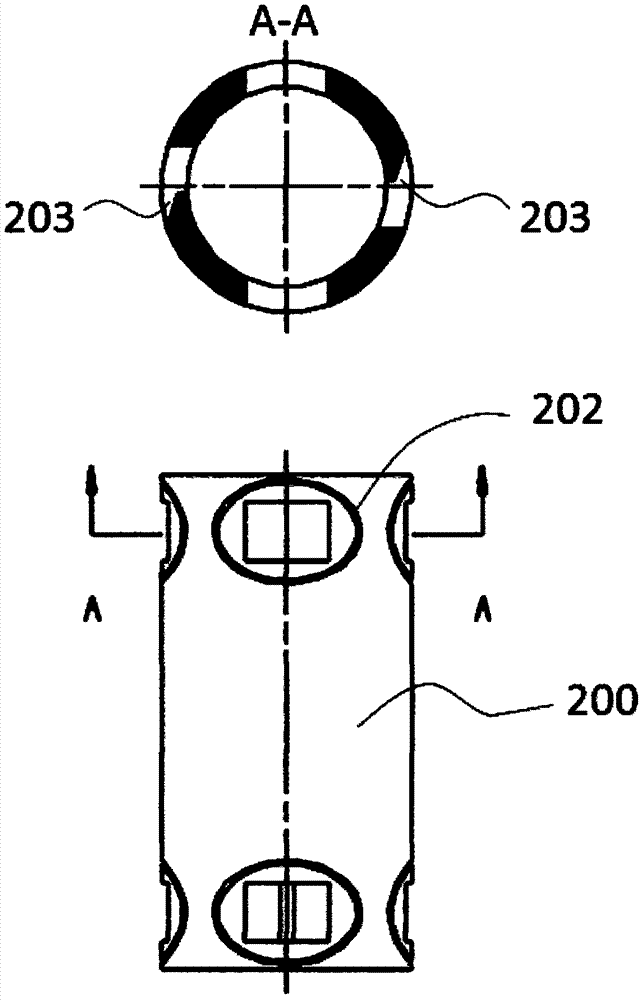

[0024] figure 1 and figure 2 A pressure exchanger is shown for transferring pressure from a high pressure fluid to a low pressure fluid. The pressure exchanger includes a body 100, a sleeve 200 arranged in the body 100, and a rotor 300 rotating in the sleeve 200. The body 100 includes two concentrated brine inlet pipes (121, 122) and two pressurized Seawater outlet pipe (111.112), and 2 seawater inlets (113.114) and 2 brine outlets (123, 124), the 8 channels 201 on the sleeve 200 are respectively connected with the water pipes (121, 122, 111, 112, 113, 114, 123, 124) aligned, through the groove 202 on the sleeve 200 to form a seal with an O-ring, when the rotor 300 rotates in the sleeve 200, the passage openings 302, 303 of the rotor 300 are respectively in contact with the sleeve The eight passages 200 on the cylinder 200 are partially or completely aligned, and the body 100 also includes two end caps (130, 140), which are screwed and fixed through the screw holes 150, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com