Belt loop forming and cutting device

A cutting device and trouser ear technology, which is applied in the field of garment processing, can solve the problems of time-consuming and laborious manual operations, low processing efficiency, and multiple operators, and achieve the effects of improving work efficiency, low defective rate, and high degree of process standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

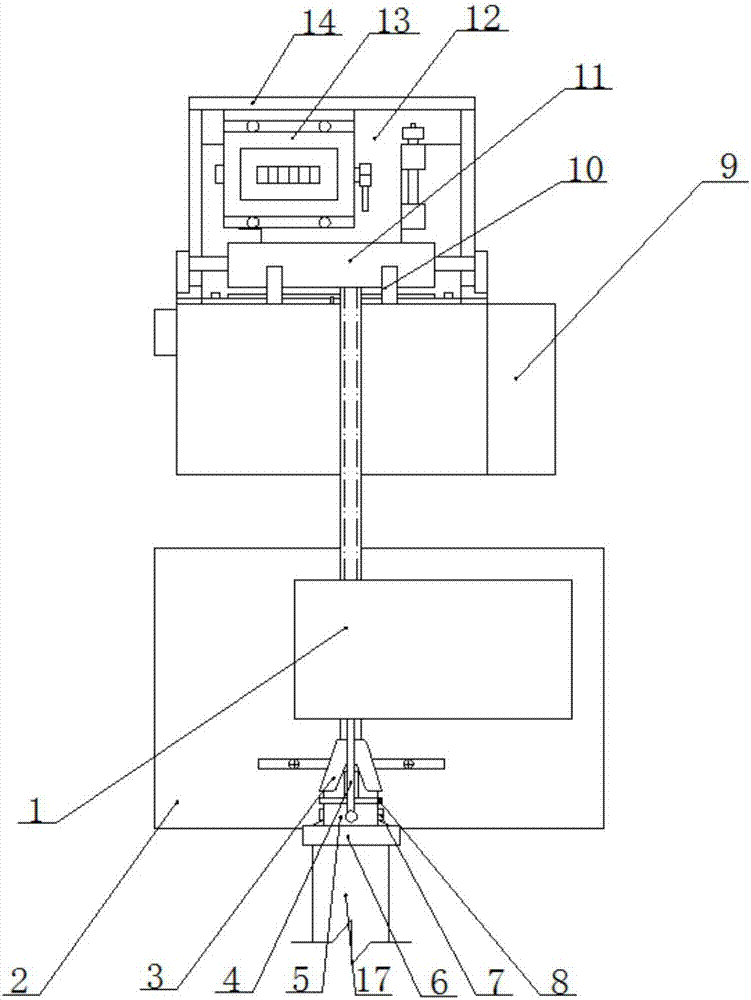

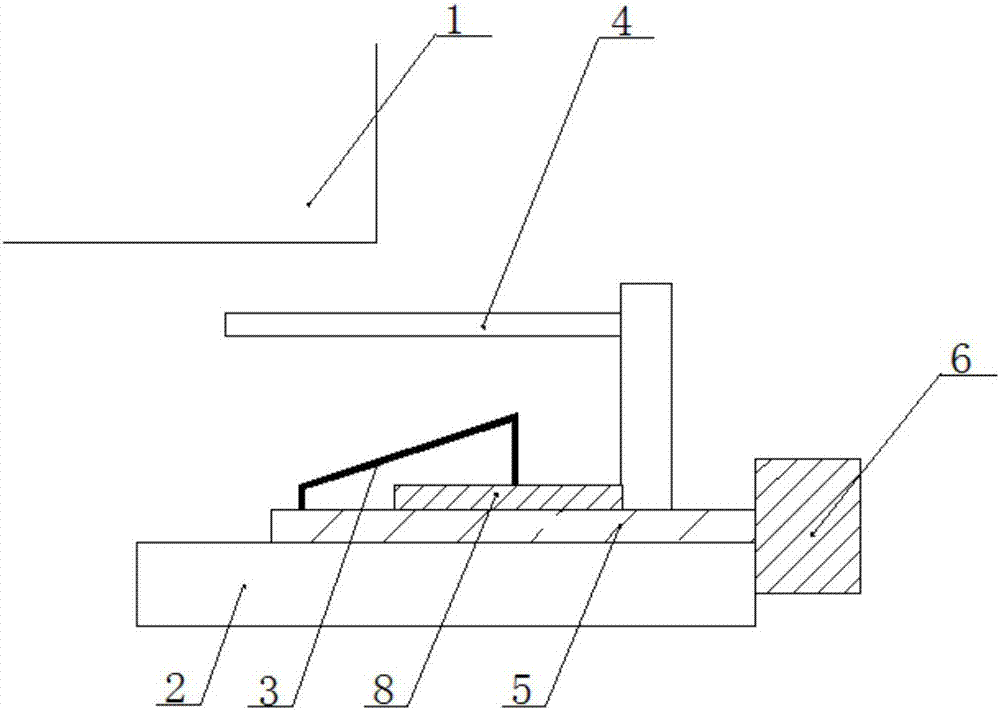

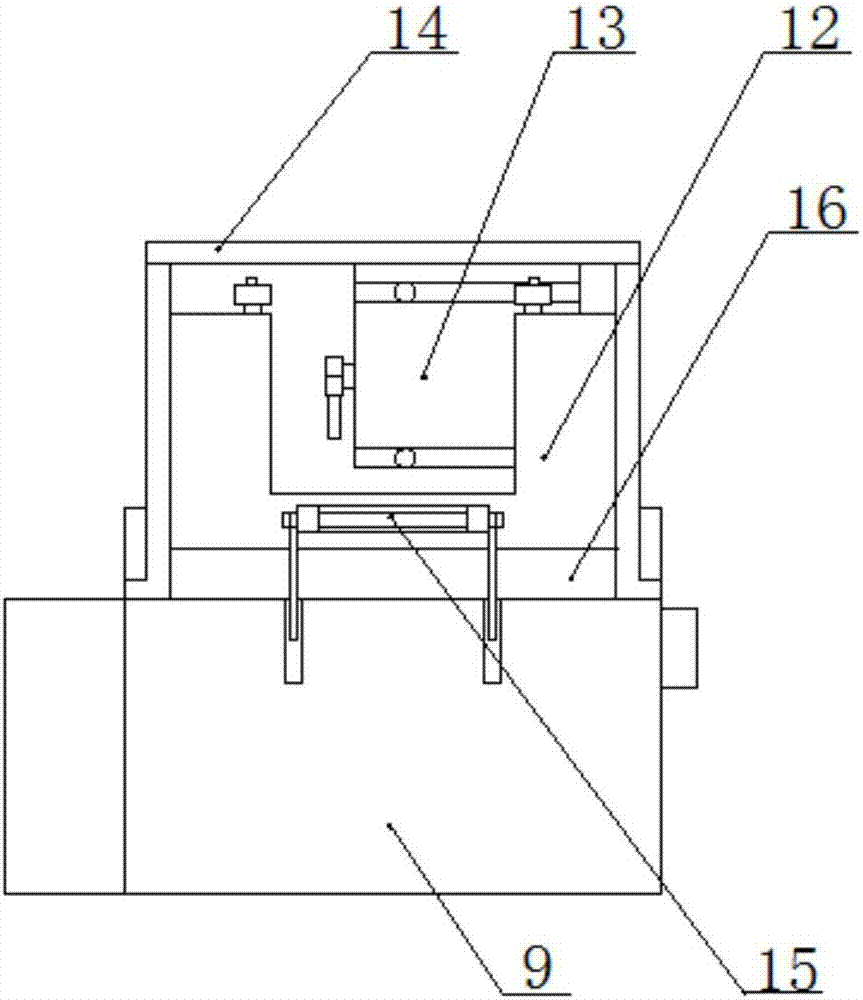

[0019] Such as figure 1 Shown, a kind of trousers ear forming cutting device is made up of trousers ear forming unit and trousers ear cutting unit, and wherein said trousers ear forming unit is hinged on sewing machine 1 (sewing machine structure belongs to known technology, repeats no more at this) machine The driving rod 4 on the head is composed of an inverted V-shaped nozzle 3 fixed on the operating table 2 below the sewing machine head and a guide mechanism fixed on the front side of the operating table. One end of the driving rod is connected under the sewing machine head. The other end is connected with the guide mechanism, and is suspended above the inverted V-shaped nozzle. The inverted V-shaped nozzle is composed of a feed sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com