Steam thermal cracking simulating experiment apparatus and technology

A simulated experimental device, thermal cracking technology, applied in the direction of non-catalytic thermal cracking, cracking, petroleum industry, etc., can solve the problems of inconvenient disassembly, maintenance operation, temperature fluctuation, increase of residence time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

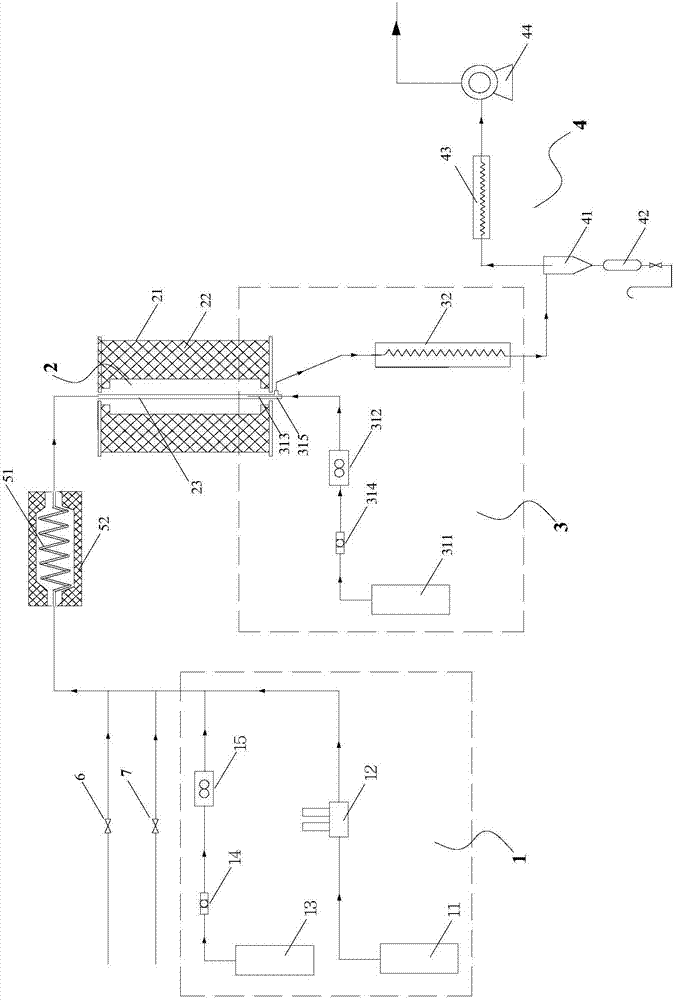

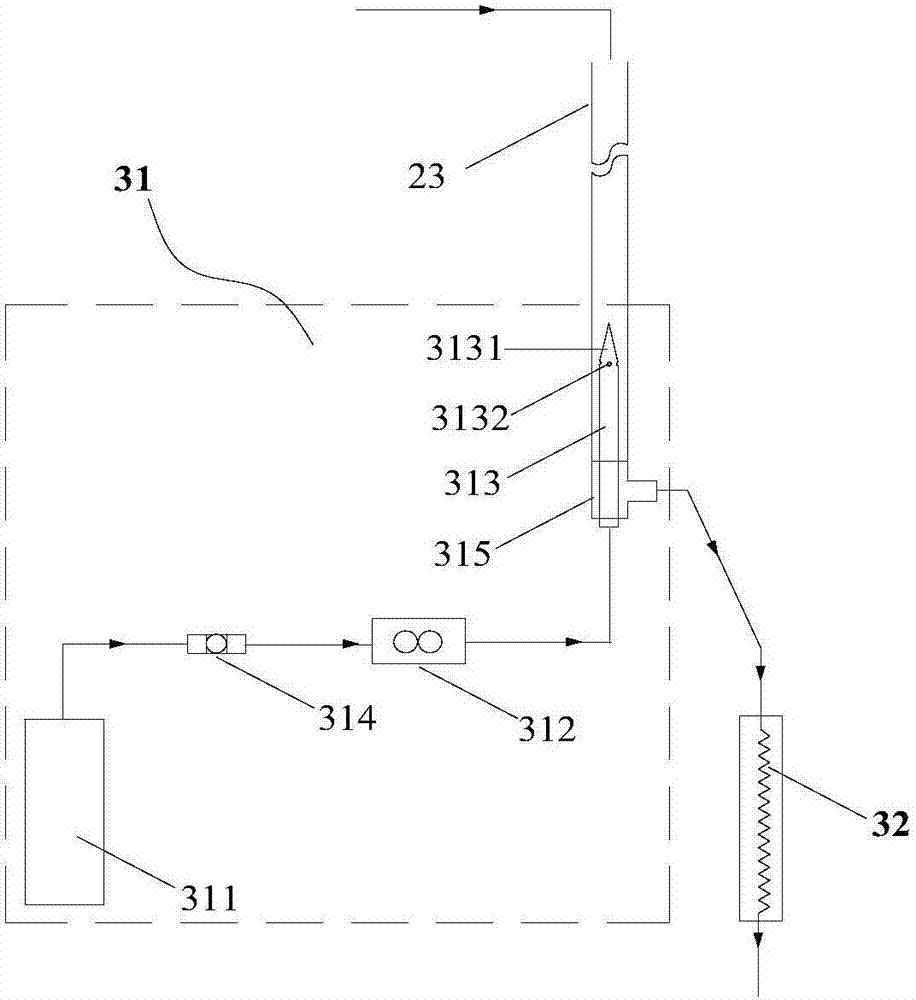

[0059] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0060] see figure 1 , figure 1 It is a schematic structural diagram of a steam pyrolysis simulation experiment device according to an embodiment of the present invention. The steam thermal cracking simulation experiment device of the present invention comprises a raw material feeding device 1 , a cracking furnace 2 , a product quenching device 3 and a product separation and recovery device 4 connected in sequence. in:

[0061] The raw material feeding device 1 comprises a raw oil storage tank 11, a raw oil feed pump 12, a water storage tank 13 and a water mass flow meter 14, wherein the raw material oil storage tank 11 and the water storage tank 13 can be pressurized to 0.1Mpa with nitrogen, and at the same time In order to reduce the viscosity of heavy raw materials, the raw oil storage tank 11 and its pipelines can be hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com