Energy-saving environment-friendly chitin deacetylation processing method

A deacetylation, energy saving and environmental protection technology, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of environmental damage, inability to control the degree of deacetylation, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

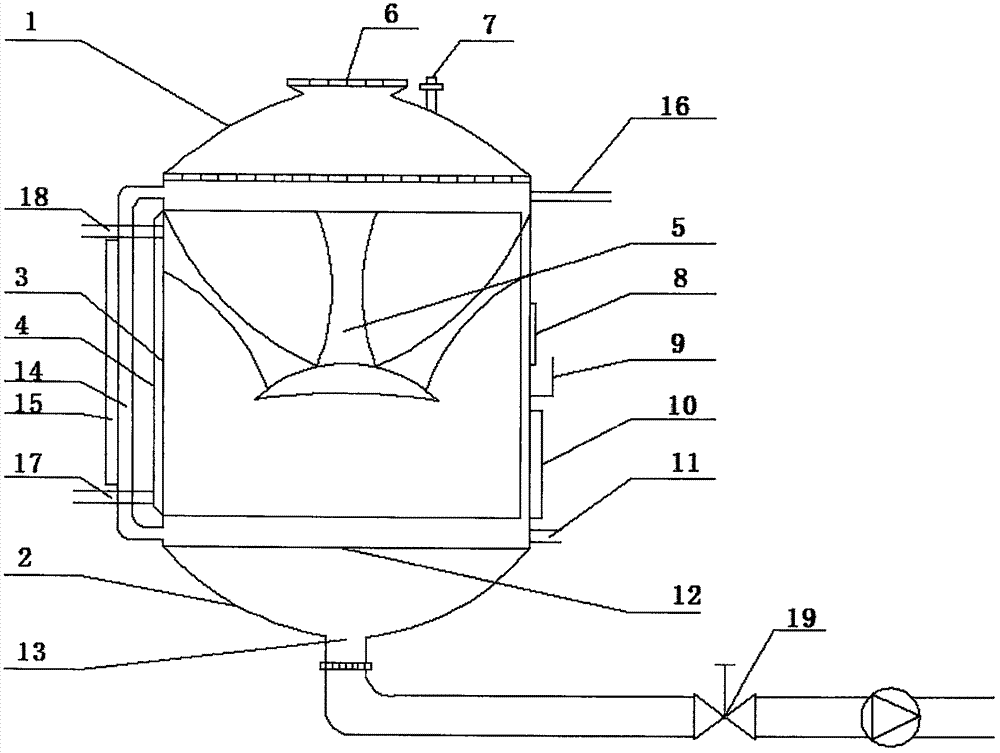

Image

Examples

Embodiment

[0026] An energy-saving and environment-friendly chitin deacetylation processing method provided by the embodiment of the present invention, the method comprises directly adding 6%-8% concentration of hydrochloric acid solution in the acid hydrolysis tank to the crab shell solid after the acid hydrolysis reaction with acetic acid compound enzyme for secondary deacetylation. Decalcification, after 4-6 hours, detect the residual calcium in the crab shell, stop the reaction when there is no residue, and remove the hydrochloric acid solution in the acid hydrolysis pool; in practical applications, the hydrochloric acid solution in the acid hydrolysis pool can be transferred to the acid storage In the tank, and pumped through the filter to the circulating acid storage tank for use. Further, the crab shell solid after the acid hydrolysis reaction with acetic acid complex enzyme is directly added into the acid hydrolysis tank with 7% hydrochloric acid solution for secondary decalcifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com