Method for producing arene and low-carbon alkene from methanol or dimethyl ether

A low-carbon olefin and dimethyl ether technology, applied in the field of circulating fluidized bed reaction-regeneration system, can solve problems such as hydrothermal deactivation of catalysts, reduction of aromatics yield, and impact on continuous and stable operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

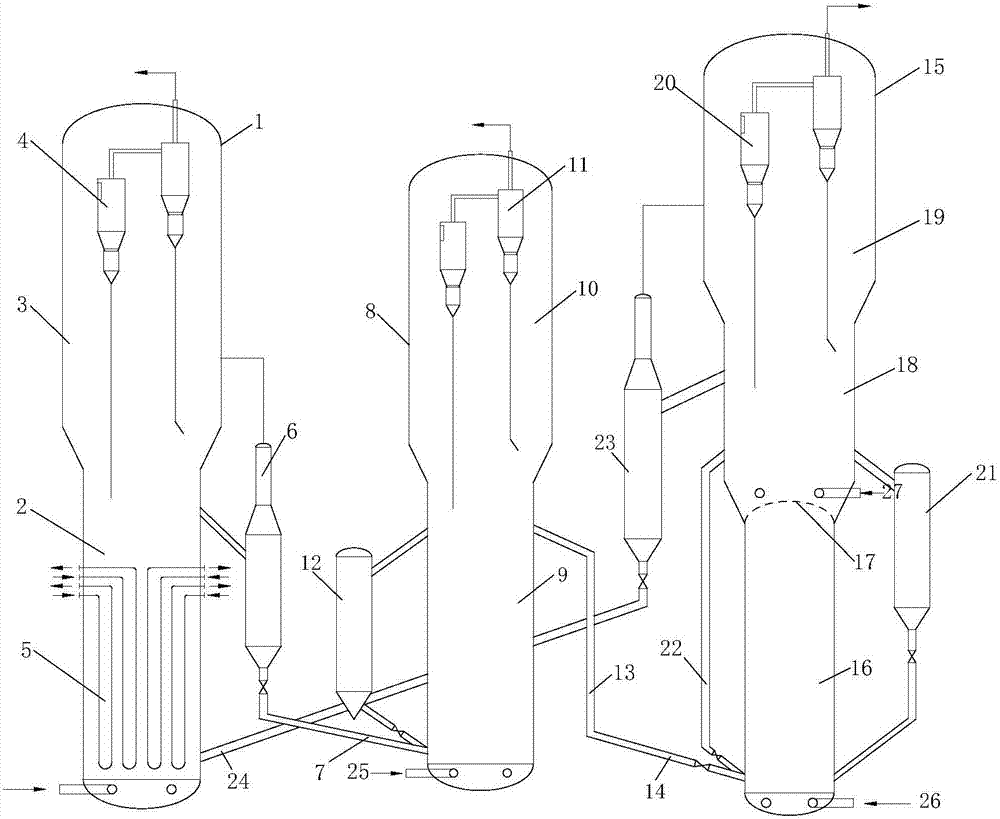

Embodiment 1

[0039] 1.8 million tons / year methanol production of aromatics and light olefins adopts such as figure 1 In the circulating fluidized bed reaction-regeneration system shown, the fluidized bed reactor is equipped with an internal heat collector, and a metal catalyst 1%Zn / 3%Ag / ZSM-5 is used. The reaction process conditions of the fluidized bed reactor are: the reaction temperature is 470°C, the reaction pressure is 0.2MPa, and the average density of the catalyst in the dense phase zone is 350 kg / m 3 , the average superficial velocity is 0.7 m / s. The regeneration process conditions of the fluidized bed regenerator are as follows: the secondary temperature is 550°C, the secondary pressure is 0.2MPa, and the average density of the catalyst in the secondary dense phase zone is 300 kg / m 3 , the average superficial linear velocity is 0.8 m / s; the fast bed temperature is 680°C, the fast bed pressure is 0.21 MPa, the average density of the fast bed catalyst is 80 kg / m, and the average s...

Embodiment 2

[0042] 1.8 million tons / year methanol production of aromatics and light olefins adopts such as figure 1 In the circulating fluidized bed reaction-regeneration system shown, the fluidized bed reactor is equipped with an internal heat collector, and a metal catalyst 1%Zn / 3%Ag / ZSM-5 is used. The reaction process conditions of the fluidized bed reactor are: the reaction temperature is 450°C, the reaction pressure is 0.3MPa, and the average density of the catalyst in the dense phase zone is 300 kg / m 3 , the average superficial velocity is 0.6 m / s. The regeneration process conditions of the fluidized bed regenerator are as follows: the secondary temperature is 540°C, the secondary pressure is 0.3MPa, and the average density of the catalyst in the secondary dense phase zone is 400 kg / m 3 , the average superficial linear velocity is 0.5 m / s; the fast bed temperature is 680°C, the fast bed pressure is 0.31 MPa, the average density of the fast bed catalyst is 50 kg / m, and the average s...

Embodiment 3

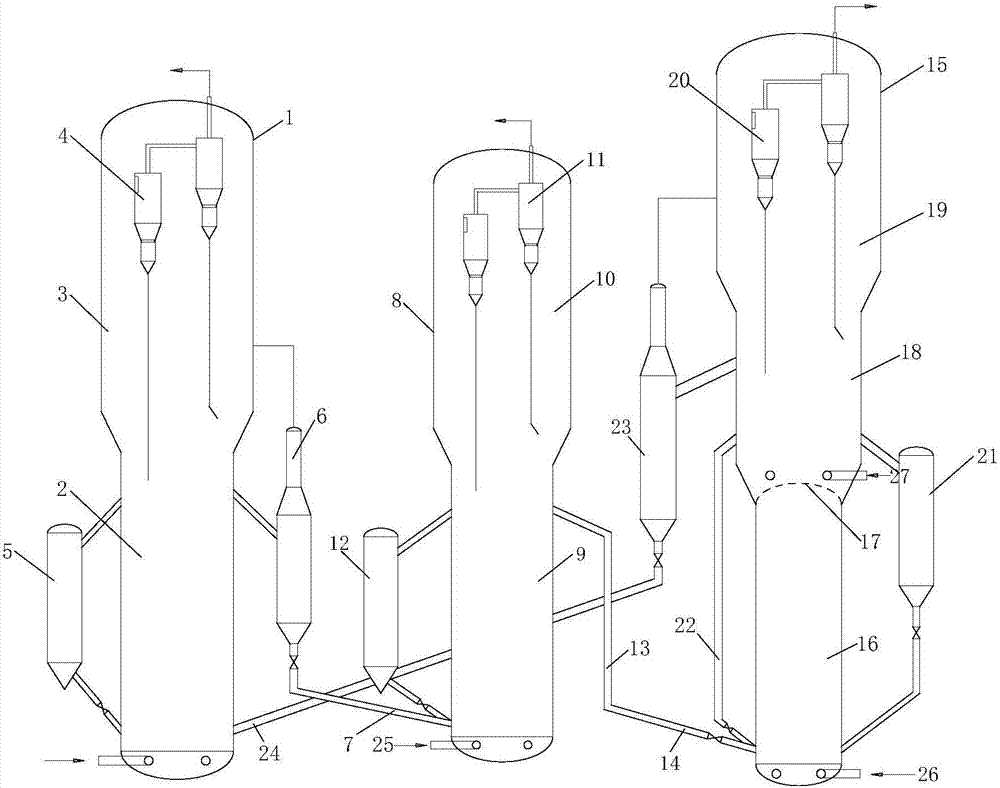

[0045] 1.2 million tons / year methanol production of aromatics and low-carbon olefins adopts such as figure 2 In the circulating fluidized bed reaction-regeneration system shown, the fluidized bed reactor is equipped with an external heat collector, and a metal catalyst 1%Zn / 3%Ag / ZSM-5 is used. The reaction process conditions of the fluidized bed reactor are: the reaction temperature is 480°C, the reaction pressure is 0.3MPa, and the average density of the catalyst in the dense phase zone is 380 kg / m 3 , the average superficial velocity is 0.8 m / s. The regeneration process conditions of the fluidized bed regenerator are as follows: the secondary temperature is 530°C, the secondary pressure is 0.3MPa, and the average density of the catalyst in the secondary dense phase zone is 350 kg / m 3 , the average superficial linear velocity is 0.6 m / s again; the fast bed temperature is 690°C, the fast bed pressure is 0.31MPa, the average density of the fast bed catalyst is 100 kg / m, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com