Method and system for treating wastewater generated during production of high-purity ultrafine modified calcium carbonate

A technology for the production of wastewater and treatment methods, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve unfavorable wastewater treatment and reuse, production and quality impact, waste of water resources and other issues, to achieve the effect of increasing production added value, high volume load, and good oxygenation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

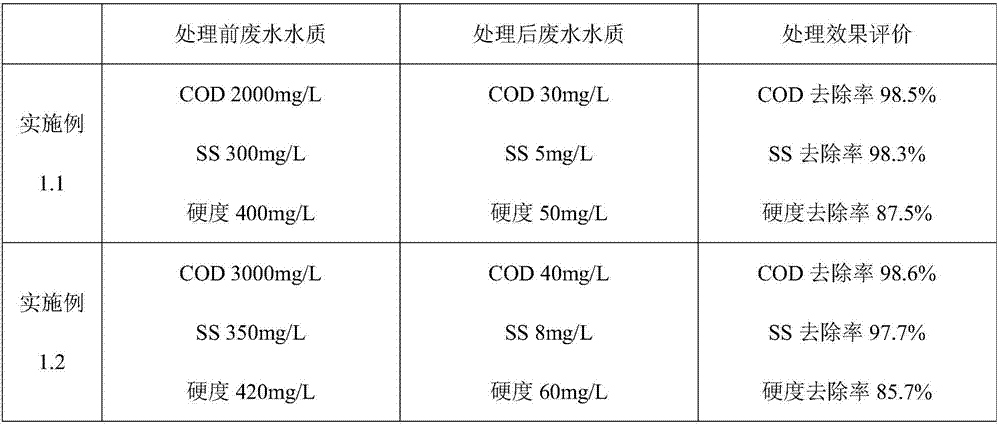

[0036] This embodiment relates to the treatment of high-purity ultrafine modified calcium carbonate production wastewater.

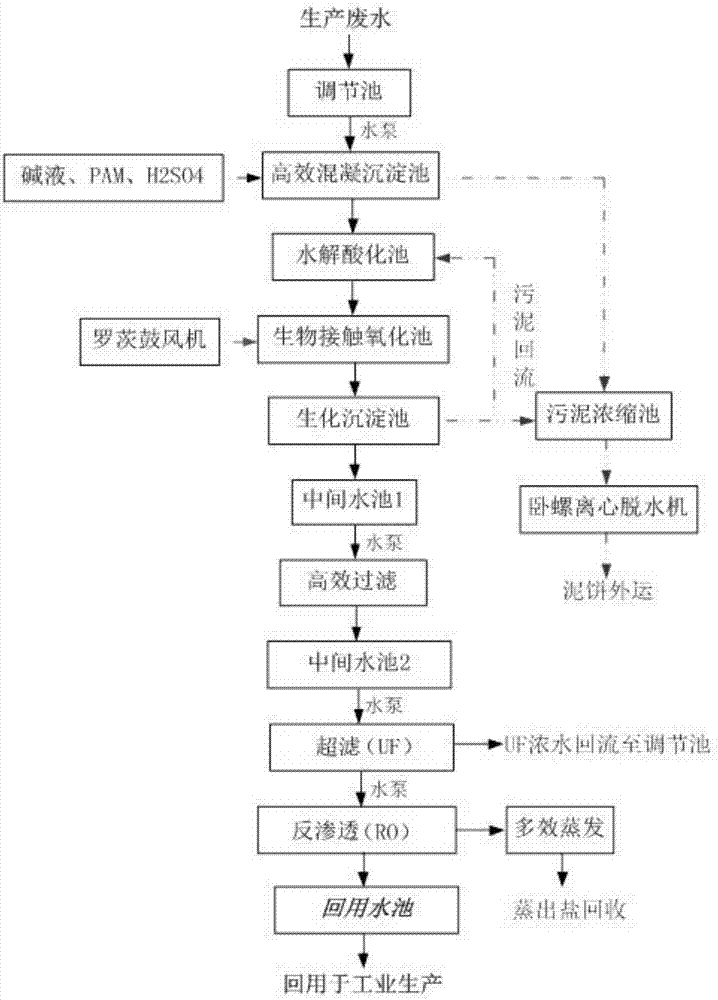

[0037] High-purity ultra-fine modified calcium carbonate production wastewater in such as figure 1 Processing is performed in the processing system shown:

[0038] Along the waste water flow direction, the treatment system includes a regulating tank, a high-efficiency coagulation sedimentation tank, a hydrolysis acidification tank, a biological contact oxidation tank and a biochemical sedimentation tank connected in sequence. It is downstream of the biochemical sedimentation tank and passes through the first intermediate tank (namely the intermediate tank 1) Connect to the high-efficiency filtration device, then connect to the ultrafiltration device through the second intermediate pool (i.e. the intermediate pool 2), and finally pass through the reverse osmosis device to connect to the reuse water pool; the reverse osmosis device is also connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com