Tire

A tire and shoulder technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problem of low cornering performance, and achieve the effect of improving cornering performance and snow performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

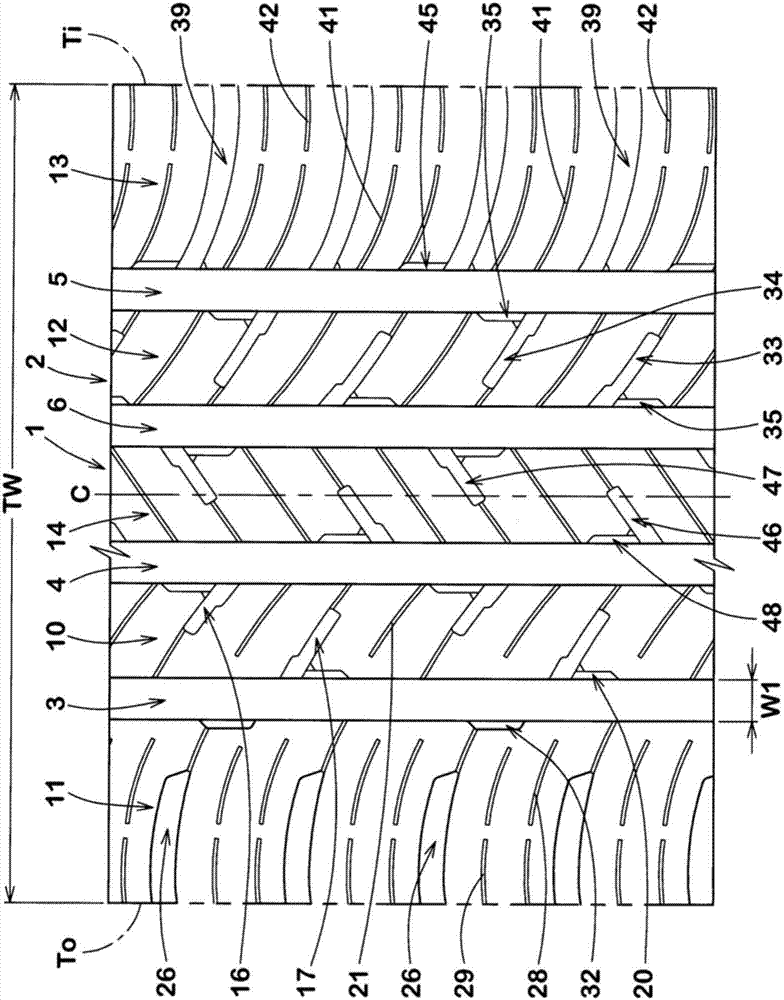

[0027] One embodiment of the present invention will be described below based on the drawings.

[0028] figure 1 It is a development view of the tread part 2 of the tire which concerns on one Embodiment of this invention. The tire 1 of the present embodiment can be used in various tires, such as pneumatic tires for passenger cars or heavy loads, and non-pneumatic tires in which pressurized air is not filled inside the tires. The tire 1 of the present embodiment is preferably applied to a pneumatic tire for passenger vehicles.

[0029] Such as figure 1 As shown, the tread portion 2 includes an asymmetrical tread pattern specifying a direction of installation to a vehicle. The tread portion 2 includes an outer tread end To located outside the vehicle when the tire 1 is installed on a vehicle, and an inner tread end Ti located inside the vehicle when the tire 1 is installed on the vehicle. The direction of installation to the vehicle is indicated by letters or symbols, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com