Fatigue-life detection method and system for aluminium alloy for railway vehicles

A rail vehicle, fatigue life technology, applied in the field of rail transit, can solve the problems that affect the normal production and delivery period of trains, long cycle, low efficiency, etc., achieve the effect of reducing technical preparation cycle, reducing test cost, and solving low efficiency

Active Publication Date: 2017-12-29

CRRC QINGDAO SIFANG CO LTD

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

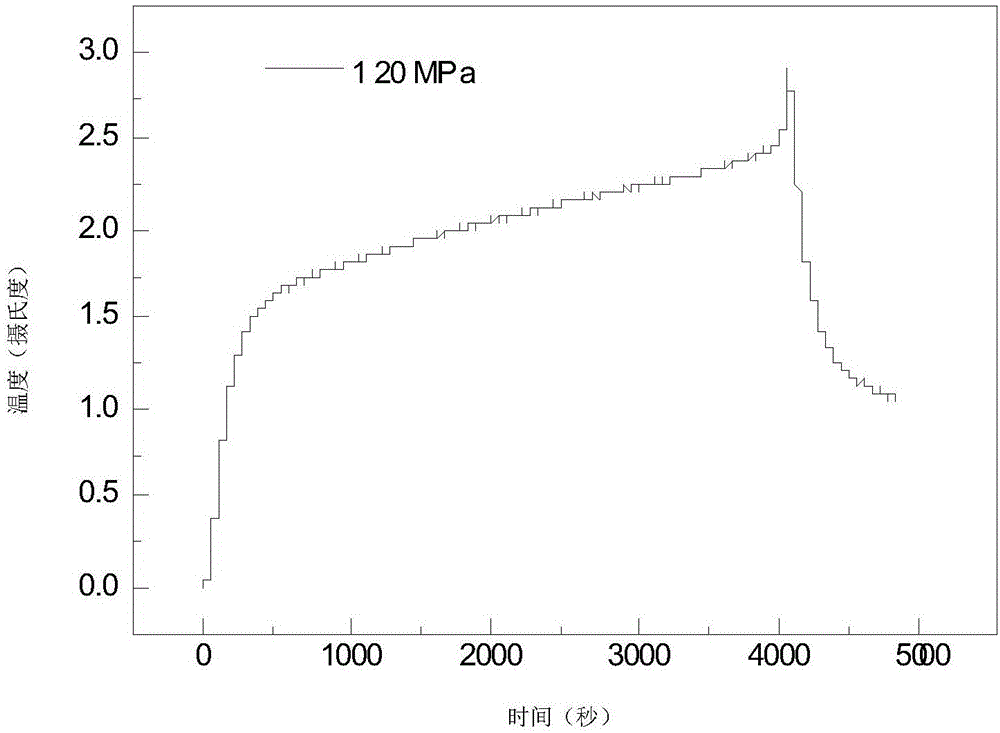

The standard fatigue test of aluminum alloys (7 series and 6 series) and its welded joints for rail vehicles is a procedure that must be passed through to inspect the quality of materials and welded joints before train production. The current fatigue test is carried out at a frequency of 10-20 Hz. There are obvious deficiencies in the low-frequency detection test, mainly manifested in low efficiency and long cycle, which often affect the normal production and delivery period of trains

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

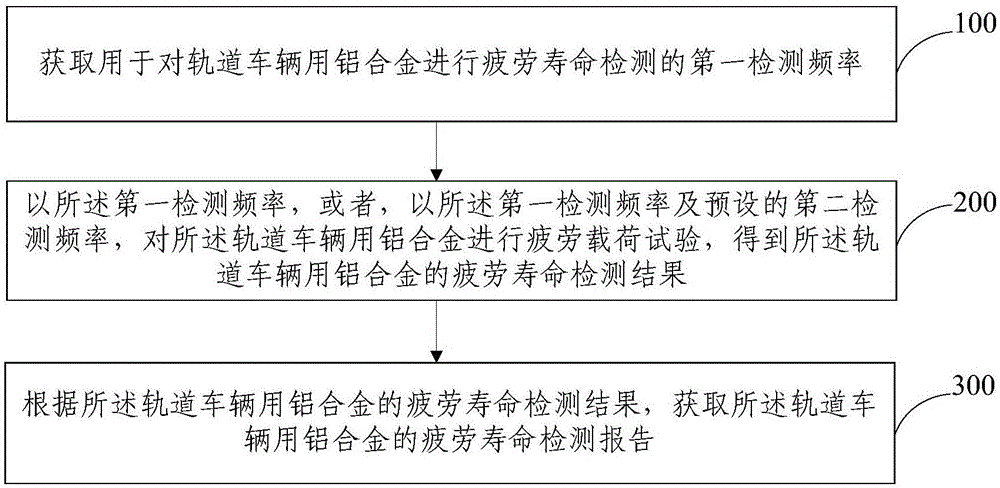

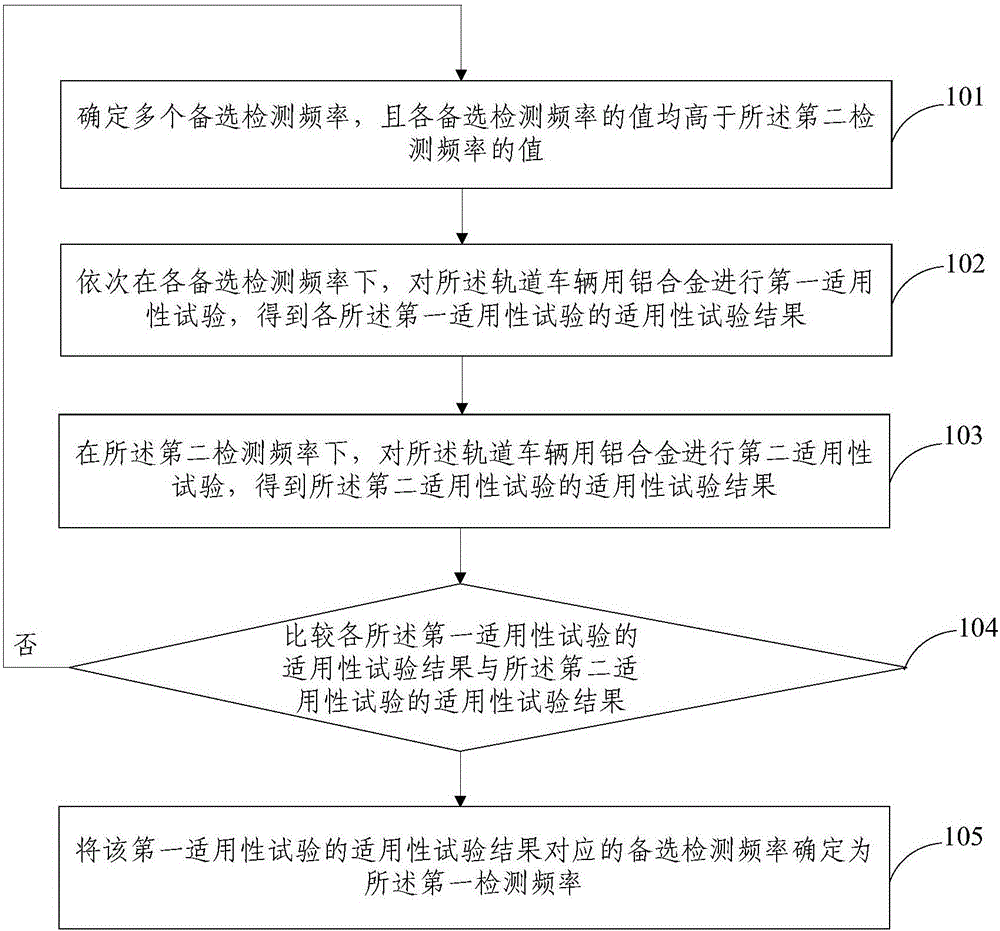

The invention provides a fatigue-life detection method and system for aluminium alloy for railway vehicles. The fatigue-life detection method comprises the following steps: acquiring first detection frequency for detecting the fatigue life of the aluminium alloy for railway vehicles; using the first detection frequency or the first detection frequency and preset second detection frequency to carry out fatigue load test on the aluminium alloy for the railway vehicles to obtain a fatigue-life detection result of the aluminium alloy for the railway vehicle, wherein the first detection frequency is higher than the second detection frequency; and acquiring a fatigue-life detection report of the aluminium alloy for the railway vehicle according to the fatigue-life detection result of the aluminium alloy for the railway vehicle. The fatigue-life detection method and system provided by the invention have the advantages that the fatigue test period of a novel material for bodies of high-speed rains is effectively and reliably shortened, the test cost is greatly reduced, the period of technical preparation of a new product is reduced, and guarantee is provided for research and development of new vehicle types such as the existing motor train units.

Description

technical field The invention relates to the technical field of rail transit, in particular to a method and system for detecting the fatigue life of aluminum alloys used in rail vehicles. Background technique The rail transit system is a transportation system that uses vehicles running on fixed guide rails in cities and is mainly used for urban passenger transport. The rail vehicles in the rail transit system are the main artery of passenger flow and the lifeline project of the city, which is directly related to the travel of urban residents. Work, shop and live. The aluminum alloy for rail vehicles and its welded joints are essential key materials and components for rail vehicles, and whether the fatigue life of aluminum alloys for rail vehicles and their welded Key to safe and reliable operation. The standard fatigue test of aluminum alloys (7 series and 6 series) and its welded joints for rail vehicles is a procedure that must be passed through to inspect the quality o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/32G01M13/00G01M17/08

CPCG01M13/00G01M17/08G01N3/32G01N2203/006

Inventor 程永明刘建孟立春方喜风

Owner CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com