Accelerated fatigue test method for front subframe

A front subframe and fatigue test technology, applied in instrumentation, geometric CAD, design optimization/simulation, etc., can solve problems such as increasing product development cycle and cost, inability to optimize program verification, and affecting project development cycle, etc., to shorten fatigue Effect of test cycle, improvement of development efficiency, and reduction of cycle times

Pending Publication Date: 2022-07-26

CHONGQING CHANGAN AUTOMOBILE CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The fatigue test period of a single-piece bench for a set of front sub-frame is about 100 hours or more (regardless of the construction time of the test tooling), and the general bench fatigue test verification requires at least three sets of parts, and a tes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

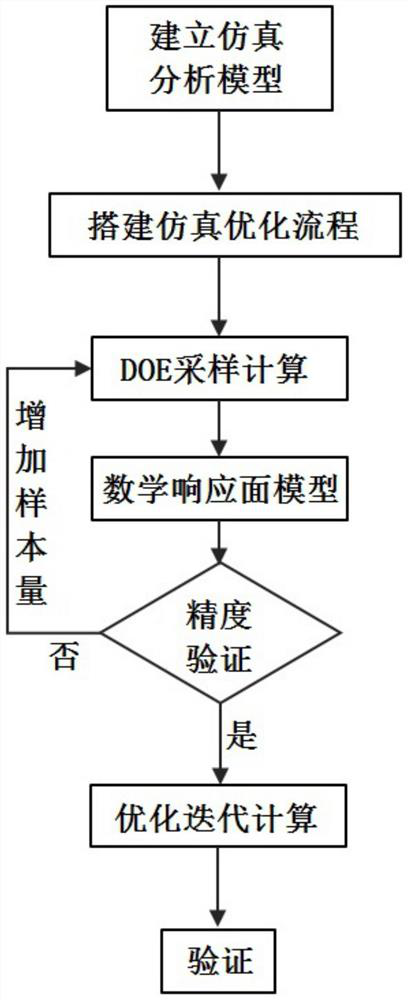

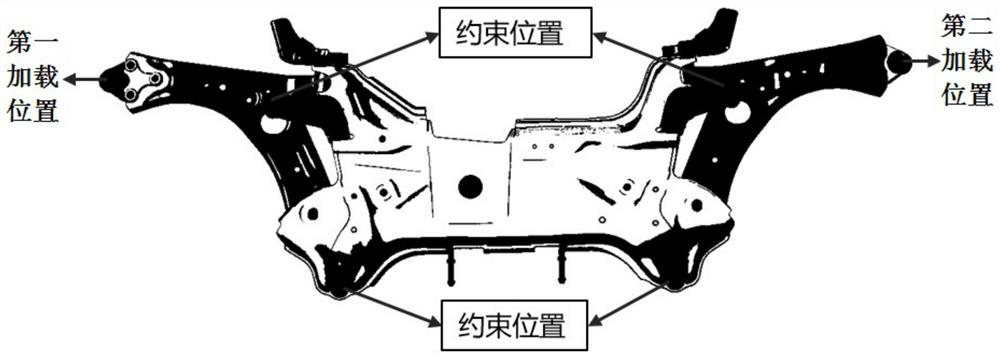

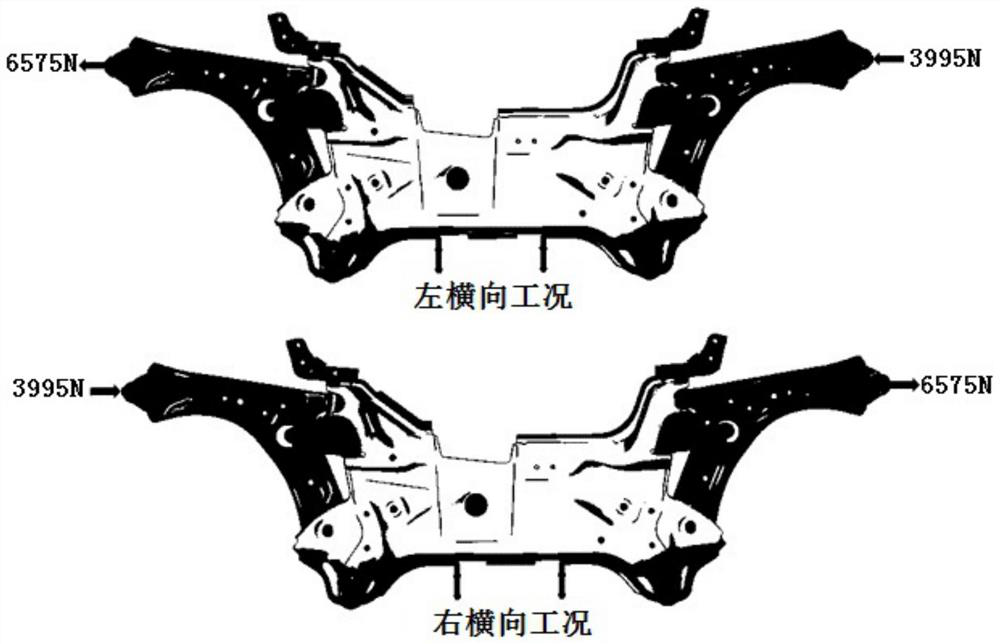

The invention discloses a front subframe accelerated fatigue test method, which comprises the following steps of: 1, establishing a simulation analysis model of a bench fatigue test of a front subframe, and performing quasi-static analysis; step 2, establishing a simulation optimization process based on a load scaling factor as a design variable, outputting a fatigue damage value with response as a key position, and carrying out DOE sampling calculation; 3, fitting a calculation result to obtain a mathematical response surface model meeting a precision requirement; step 4, according to the obtained mathematical response surface model, performing optimization by taking the load scaling factor as a variable, taking a fatigue damage value of a critical position as a constraint and taking a minimum damage target error as a target to obtain an optimal solution of the load scaling factor; and 5, calculating to obtain an optimized load, loading the front auxiliary frame, setting the cycle index as the optimized cycle target number, and carrying out a bench fatigue test. The fatigue test cycle index can be reduced, the fatigue test period is shortened, and the development efficiency is improved.

Description

technical field [0001] The invention relates to a bench fatigue test of auto parts, in particular to an accelerated fatigue test method of a front subframe. Background technique [0002] The component-level bench fatigue test is generally carried out before the test and verification of the whole vehicle and system. The purpose is to check the fatigue and durability problems of each product component in advance, so as to make the test and verification of the whole vehicle and system pass as much as possible at one time, which can shorten the development cycle. , reduce development costs. [0003] The fatigue test cycle of a single-piece bench for a set of front subframes is about 100 hours or more (not considering the time to build the test tool). Generally, at least three sets of parts are required for the verification of the bench fatigue test, and at least 15 days are required. It will greatly affect the project development cycle. In the process of test verification, if ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F30/23G06F30/15G06F119/14

CPCG06F30/23G06F30/15G06F2119/14

Inventor 徒高桥龙弟德禹慧丽毛显红曾庆强董泽胡碧俊

Owner CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com