Fatigue test device for compression spring

A fatigue test, compression spring technology, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problem of long fatigue test period of compression springs, and achieve simple structure, reasonable design and good economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

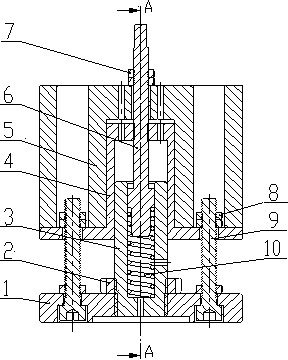

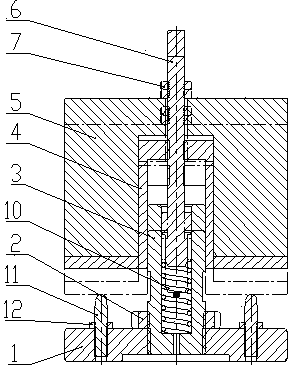

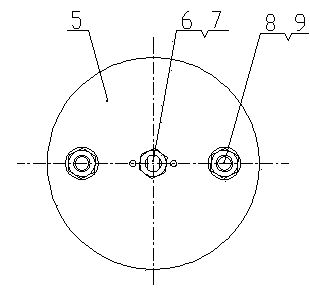

[0018] see figure 1 with image 3 , the fatigue test device for compression springs includes a circular base 1, the center of the base 1 is provided with an upright spring sleeve 3, the base 1 and the spring sleeve 3 are threaded, and the thread of the spring sleeve 3 A round nut 2 that plays a locking role is installed in conjunction with it. Two upright screw rods 9 and two upright limit screws 11 are evenly distributed on the circumference of the base 1, the two screw rods 9 are of equal height, and the two limit screws 11 are of equal height; and the height of the limit screw 11 is less than that of the screw rod 9 in height. The upper part of the spring sleeve 3 is covered with a cylindrical loading support 4, and the spring sleeve 3 is connected with a coaxial pre-tightening pressure rod 6 by threads, and the bottom of the pre-tightenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com