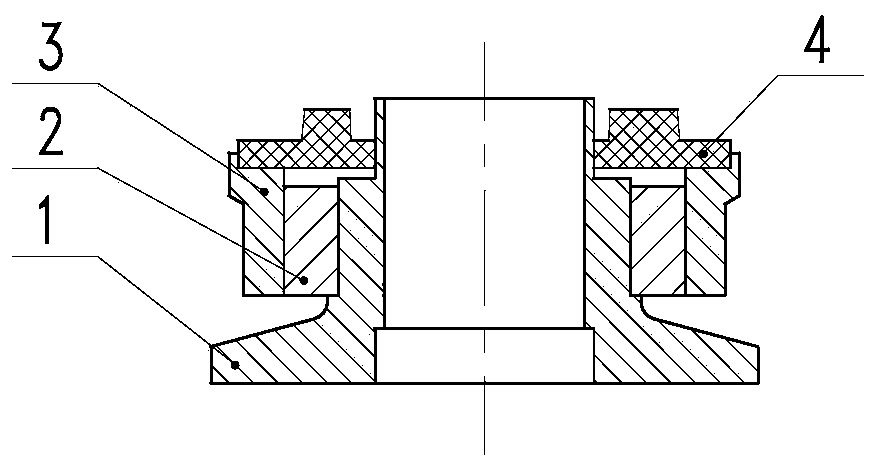

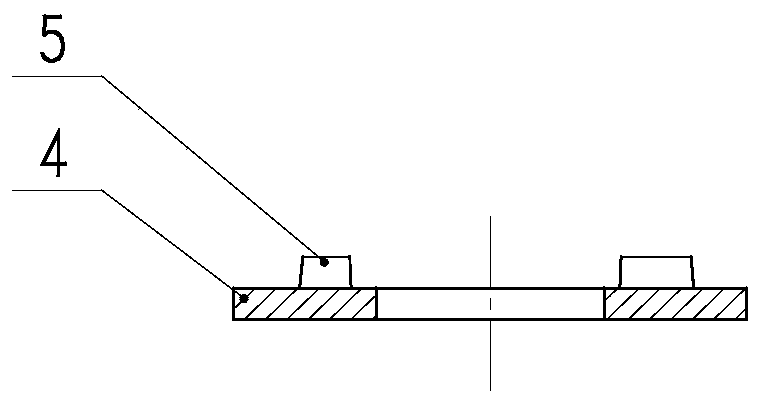

Built-in amplifying circuit ring shear piezoelectric component structure

A technology of circular cutting and amplifying circuits, which is applied in the direction of measuring devices, electric devices, and electromagnetic means, etc., can solve the problem of small effective connection length or rigid section of the center bottom hole thread, no effective and reliable built-in circuit installation structure and space, etc. Unable to withstand a large number of shocks and vibrations, etc., to improve the ability to withstand a large number of non-destructive shocks and vibrations, to facilitate the layout of rounded corners, and to avoid line interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A certain model product of our company is developed using the technology involved in the present invention. PZT piezoelectric ceramic is selected as the piezoelectric element. The double-ended floating signal output, the sensitivity is 25mV / g, and the center hole M4 screw realizes the installation of any wire throwing in 360° direction. The interference ability is strong, and the frequency response error in the 12.8kHz range can be no more than 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com