Electrohydraulic control method and device for axial flow propeller turbine runner tests

An electro-hydraulic control and water turbine technology, which is used in fluid pressure actuation devices, machine gear/transmission mechanism testing, accumulator devices, etc. It can solve the problem of high repair costs, threats to the sealing performance of seals, joint collapse and fuel injection and other problems, to achieve the effect of good application effect, ensuring pressure safety, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

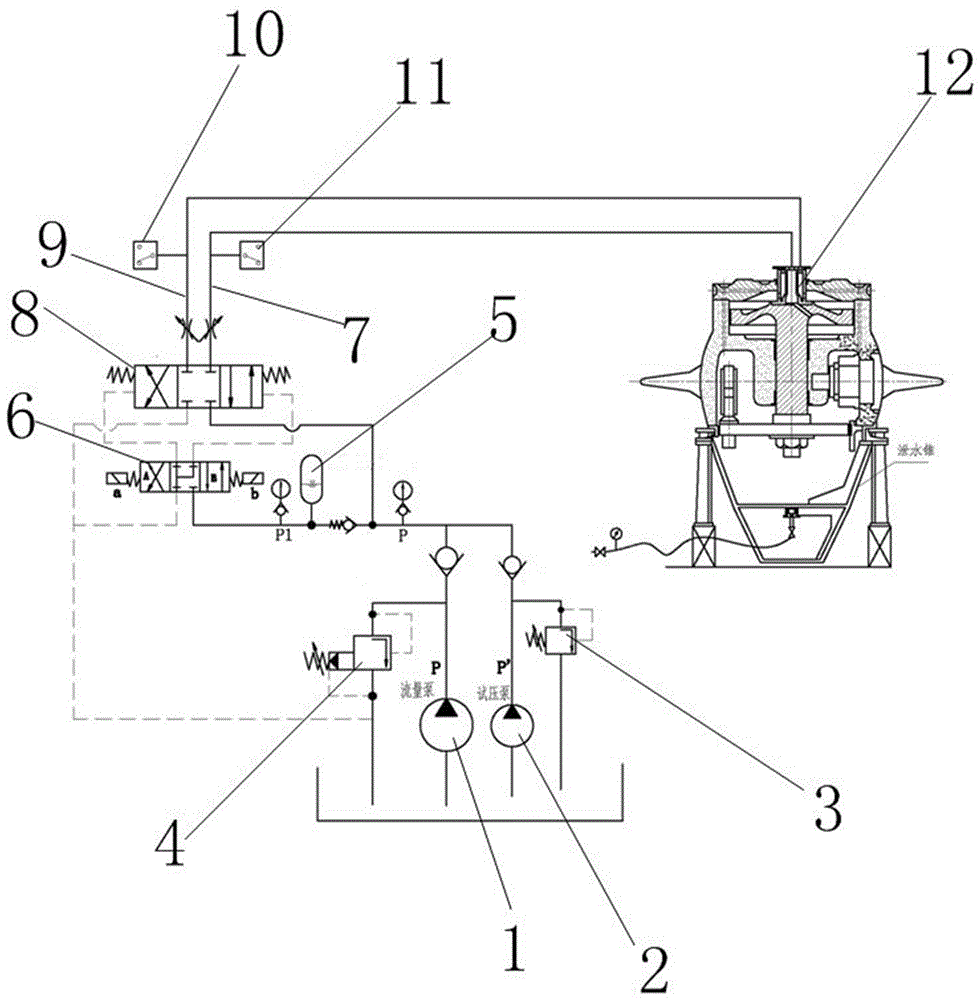

[0034] Such as Figure 1-3As shown, the electro-hydraulic control device for the axial flow paddle turbine runner test, the control device includes a flow pump 1, a pressure test pump 2, an oil circuit and an oil pressure control mechanism; the output pressure of the flow pump 1 is lower than that of the pressure test pump 2 ; The flow pump and the pressure test pump are connected to each other through the oil circuit with the runner 12 of the axial flow paddle turbine to be tested, and the oil pressure control mechanism is located at the oil circuit; the oil pressure control mechanism includes an electro-hydraulic converter The electro-hydraulic reversing assembly includes the electro-hydraulic reversing valve 6 for control, the electro-hydraulic reversing valve 8 for business and the accumulator 5; the electro-hydraulic reversing valve 6 for control and the electro-hydraulic reversing valve connected to the valve 8 to amplify the driving force of the oil circuit; the accumul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com