Preparation method of hollow carbon nanospheres with internal confined growth MOFs

A nanosphere and hollow carbon technology, applied in nanocarbon, nanotechnology and other directions, can solve the problems of non-conductivity of MOFs materials, unguaranteed material stability, limited application in the field of electrochemistry, etc., and achieve good morphology control. , The effect of low toxicity of materials and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

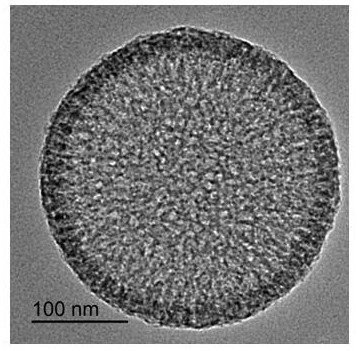

[0036] 1. Synthesis of mesoporous hollow carbon nanospheres:

[0037] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia, add 0.6 g of tetraethylorthosilicate (TEOS) slowly and dropwise to the mixture at a uniform speed, stir mechanically at room temperature, and react for 10 min to form SiO 2 Nanosphere.

[0038] Then, 1 ml of formaldehyde and 0.5 g of resorcinol were added to the above reaction system, and the reaction was mechanically stirred for 24 h at room temperature. After centrifugal washing, the solid phase was dried at 60°C for 12 hours to form SiO 2 @Resorcinol-formaldehyde resin.

[0039] The dried SiO 2 @Resorcinol-formaldehyde resin is calcined at 700℃ for 5h under the protection of argon atmosphere, heating rate is 2℃ / min, then SiO is obtained 2 @C球.

[0040] The calcined SiO 2 @C spheres are dispersed in 50 ml, 2 mol / L sodium hydroxide aqueous solution, etched at 60℃ for 16 h, after the reaction is over, washed with water and ethanol by centrifugation ...

Embodiment 2

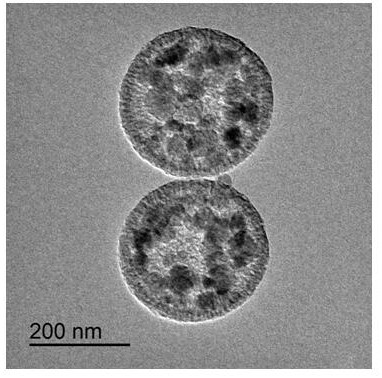

[0047] 1. Synthesis of mesoporous hollow carbon nanospheres:

[0048] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia water, and then add 0.6 g of tetraethyl orthosilicate (TEOS) slowly and uniformly into the mixed solution, stir mechanically at room temperature, and react for 10 min to form SiO 2 Nanosphere.

[0049] Then, 1 ml of formaldehyde and 0.5 g of resorcinol were added to the above reaction system, and the reaction was mechanically stirred for 24 h at room temperature. After centrifugal washing, the solid phase is dried at 60°C for 12 hours to form SiO 2 @Resorcinol-formaldehyde resin.

[0050] The dried SiO 2 @Resorcinol-formaldehyde resin is calcined at 700℃ for 5h under the protection of argon atmosphere, heating rate is 2℃ / min, then SiO is obtained 2 @C球.

[0051] The calcined SiO 2 @C spheres are dispersed in 50 ml, 2 mol / L sodium hydroxide aqueous solution, etched at 60°C for 16 h, after the reaction is over, washed with water and ethanol by centrif...

Embodiment 3

[0058] 1. Synthesis of mesoporous hollow carbon nanospheres:

[0059] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia, add 0.6 g of tetraethyl orthosilicate (TEOS) slowly and dropwise to the mixed solution at a uniform speed, stir mechanically at room temperature, and react for 10 min to form SiO 2 Nanosphere.

[0060] Then, 1 ml of formaldehyde and 0.5 g of resorcinol were added to the above reaction system, and the reaction was mechanically stirred for 24 h at room temperature. After centrifugal washing, the solid phase is dried at 60°C for 12 hours to form SiO 2 @Resorcinol-formaldehyde resin.

[0061] The dried SiO 2 @Resorcinol-formaldehyde resin is calcined at 700℃ for 5h under the protection of argon atmosphere, heating rate is 2℃ / min, then SiO is obtained 2 @C球.

[0062] The calcined SiO 2 @C spheres are dispersed in 50 ml, 2mol / L aqueous hydroxide solution, etched at 60℃ for 16 h, after the reaction is over, washed with water and ethanol by centrifugation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com