Stamping method for all-round three-head stamping machine

A kind of stamping machine and all-round technology, which is applied in the stamping field of the all-round three-head stamping machine, which can solve the problems of poor positioning of the stamping position, insufficient clear and complete printing, poor seal protection, etc., to ensure integrity and clarity , the seam seal is complete and clear, and the effect of improving the quality of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

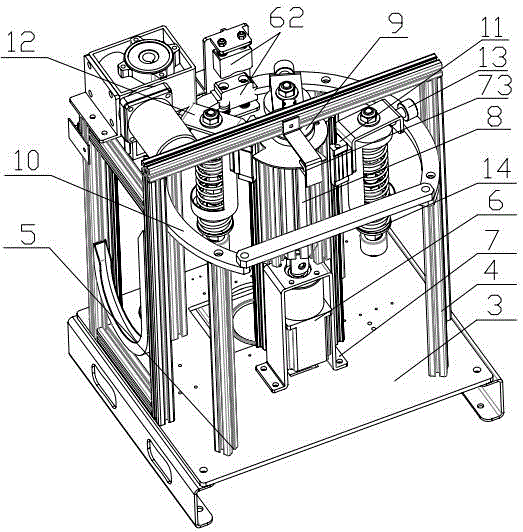

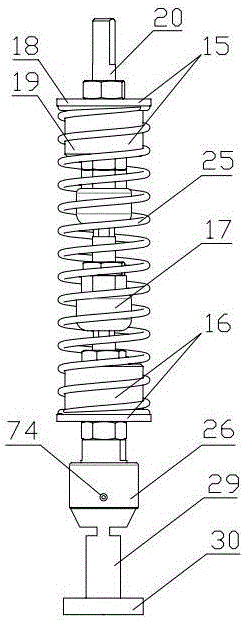

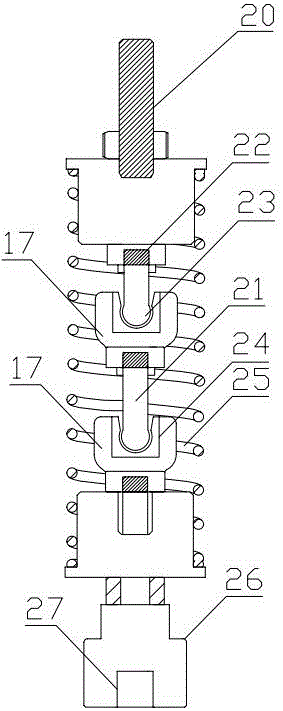

[0052] An all-round three-head stamping machine, including a head 1 and a base 2, a housing is arranged inside the head 1, as attached figure 1 As shown, the housing is provided with a fixed frame, and the fixed frame includes a base plate 2, an inverted U-shaped frame 4 and a plurality of vertical frames 5, and the inverted U-shaped frame 4 and the vertical frames 5 are fixed on the base plate 3 Above, the housing is provided with a control unit, a rotating mechanism, a double ball joint spring arm 14, an ink cartridge mechanism, a laser indicator mechanism and a lifting mechanism, and the ink ink cartridge mechanism and the laser indicator mechanism are arranged below the bottom plate 3, And cooperate with the rotating mechanism, the double ball joint spring arm and the lifting mechanism arranged on the top of the base plate 3 to complete the stamping operation by receiving the driving signal sent by the control unit.

[0053] as attached figure 1 As shown, the rotating mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com