Dedusting color sand vibrating screen

A vibrating sieve and colored sand technology, which is applied in the fields of filtering, separation, grain processing, etc., can solve the problems of impact, the surrounding environment of the vibrating sieve is not suitable for operation, and the consumer experience is not good, so as to achieve the effect of reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

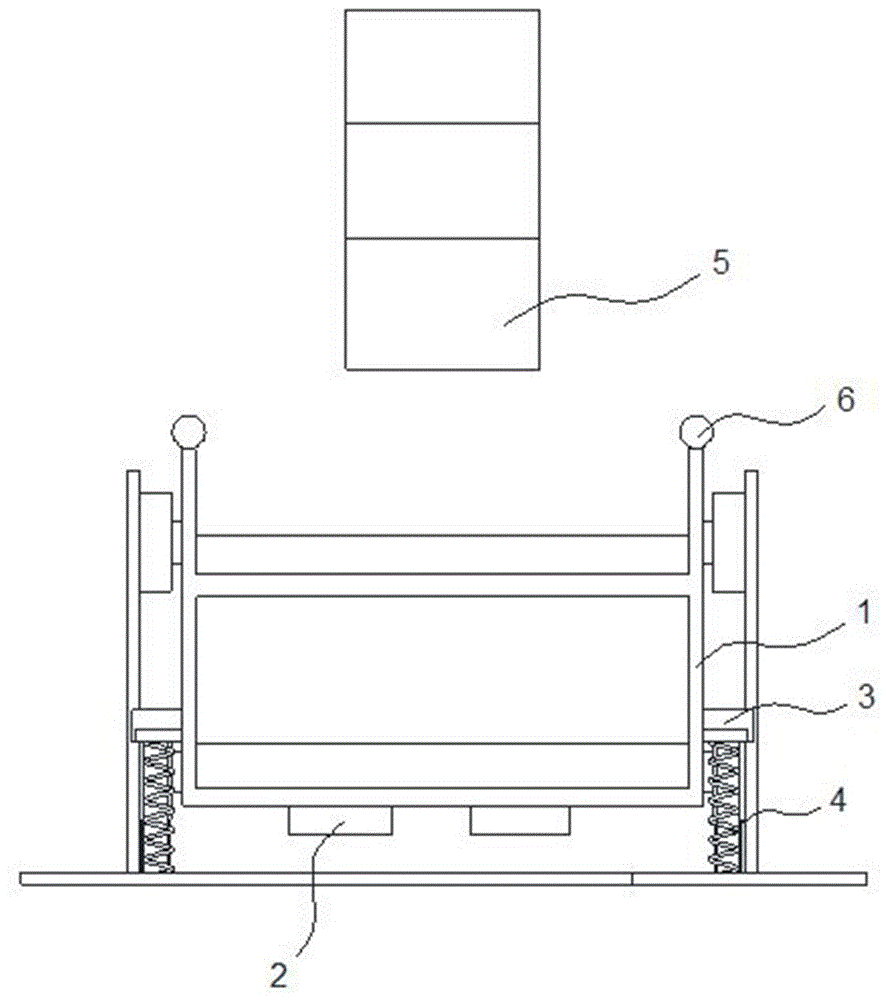

[0028] Such as Figure 1 to Figure 4 As shown, the vibrating screen includes a base and a screen box 1 , a screen 11 is arranged inside the screen box 1 , and a vibrator 2 is arranged on the screen box 1 . The screen box 1 includes a main body of the screen box 1 and limiting bodies 3 located on both sides of the main body, and a spring supporting device 4 is arranged between the limiting body 3 and the bottom plate. The base is provided with a support, and the support is provided with an exhaust device 5, which includes an air duct 51 extending outward from the top of the screen box 1, a fan located in the air duct 51, and a fan blade located at the mouth of the air duct 51. 52. The fan blade 52 includes a fan blade main body 521 and a particle board 522 that is rotatable relative to the fan blade main body 521 near the screen box 1 side. A water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com