Ultrasonic transducer with micro-broadband power adapting to frequency drift

An ultrasonic transducer, frequency drift technology, applied in the direction of the fluid using vibration, etc., can solve the problem that the output power and amplitude cannot be guaranteed, and achieve obvious effects and avoid the effect of amplitude attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

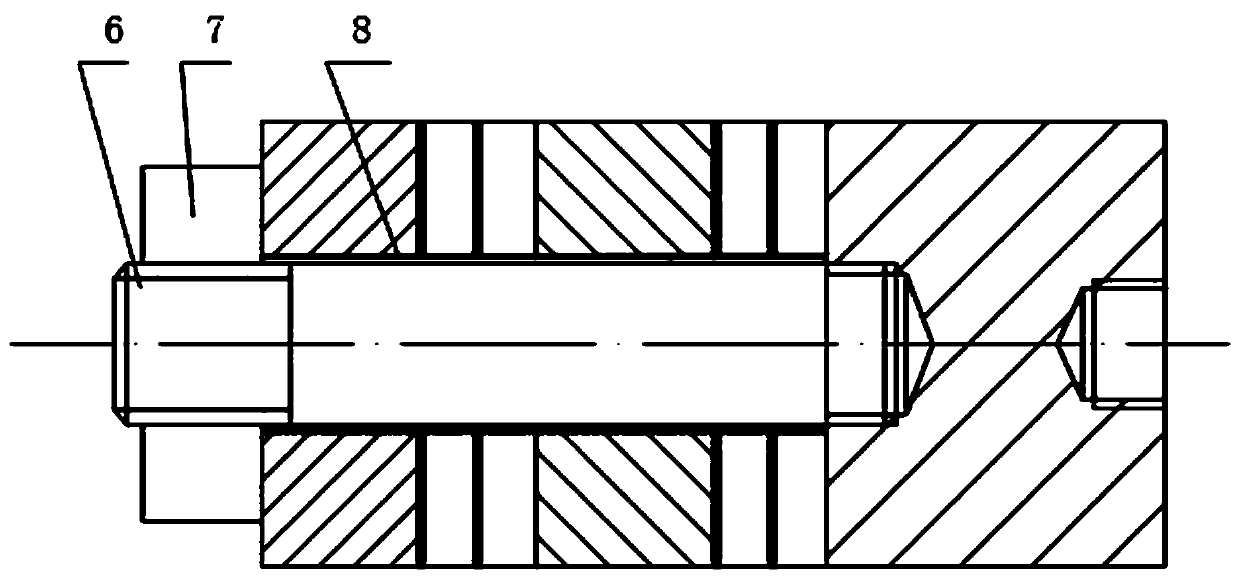

[0056] The rear cover 1 , the first group of piezoelectric ceramic crystal piles 2 , the middle cylinder 3 , the second group of piezoelectric ceramic crystal piles 4 and the front cover 5 are connected together by pretightening studs and nuts 7 . Wherein the thread of one end of the pretightening stud screwed into the front cover plate 5 is completely screwed in according to the standard, and the other end is connected with the nut;

[0057] The ceramic sheets and copper electrode sheets in the first group of piezoelectric ceramic crystal stacks 2 are connected by vacuum cold pressure welding, and then enter the assembly of the transducer;

[0058] The ceramic sheets and copper electrode sheets in the second group of piezoelectric ceramic crystal stacks 4 are connected through vacuum cold pressure welding, and then enter the assembly of the transducer;

[0059] The copper electrodes in the first group of piezoelectric ceramic crystal stacks 2 are connected to the low-frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com