Flexible OLED display device stripping method and flexible OLED display device

A display device and flexible technology, applied in the field of OLED display, can solve the problems of high cost of laser equipment, cracking, damage to OLED display devices, etc., and achieve the effect of improving the yield rate of the stripping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

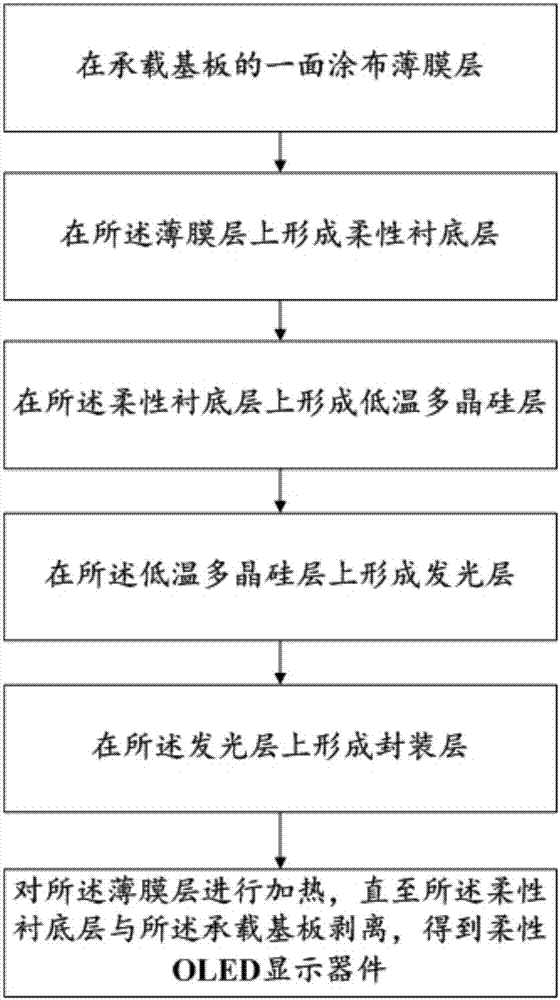

[0025] The invention provides a method for peeling off a flexible OLED display device, such as figure 1 , figure 2 As shown, the method includes the following steps:

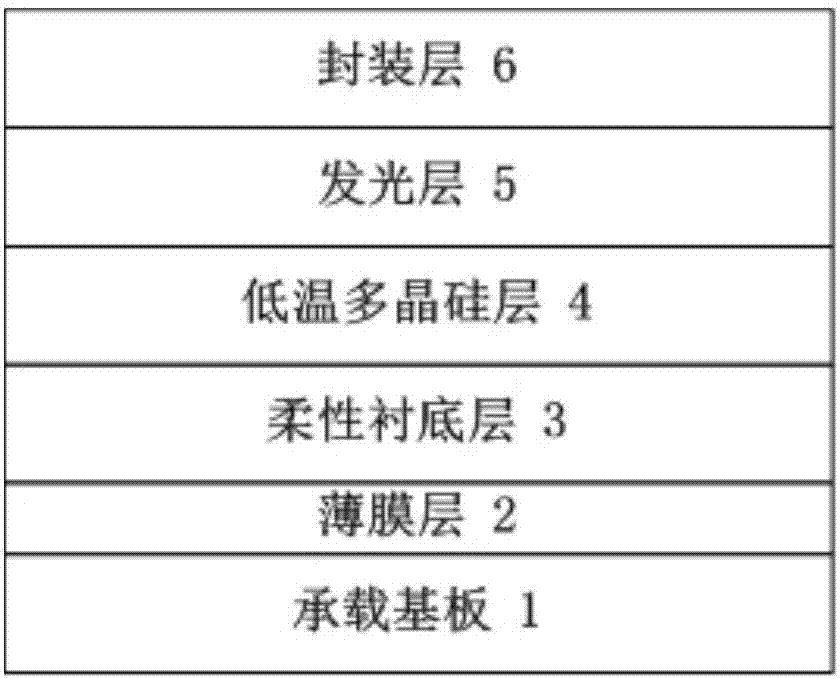

[0026] A film layer 2 is coated on one side of the carrier substrate 1, wherein the carrier substrate 1 is one of a glass plate, an acrylic plate, and a metal plate with a rough surface, and the material of the film layer 2 is naphthalene, phosphorus pentachloride, or an amine compound , polyalcohol compound, at least one of paraffin.

[0027] A flexible substrate layer 3 is formed on the film layer 2 .

[0028] A low temperature polysilicon layer 4 is formed on the flexible substrate layer 3 .

[0029] A light emitting layer 5 is formed on the low temperature polysilicon layer 4 .

[0030] The encapsulation layer 6 is formed on the light emitting layer 5 .

[0031] The thin film layer 2 is heated until the flexible substrate layer 3 is peeled off from the carrier substrate 1 to obtain a flexible OLED disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com