Testing device and testing method for magnetic flux leakage of petroleum gas storage well casing

A testing device and gas storage well technology, which is applied to electromagnetic measuring devices, measuring devices, electrical devices, etc., can solve the problems of incomplete detection and great influence, and achieve the effects of large amount of information, high accuracy and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

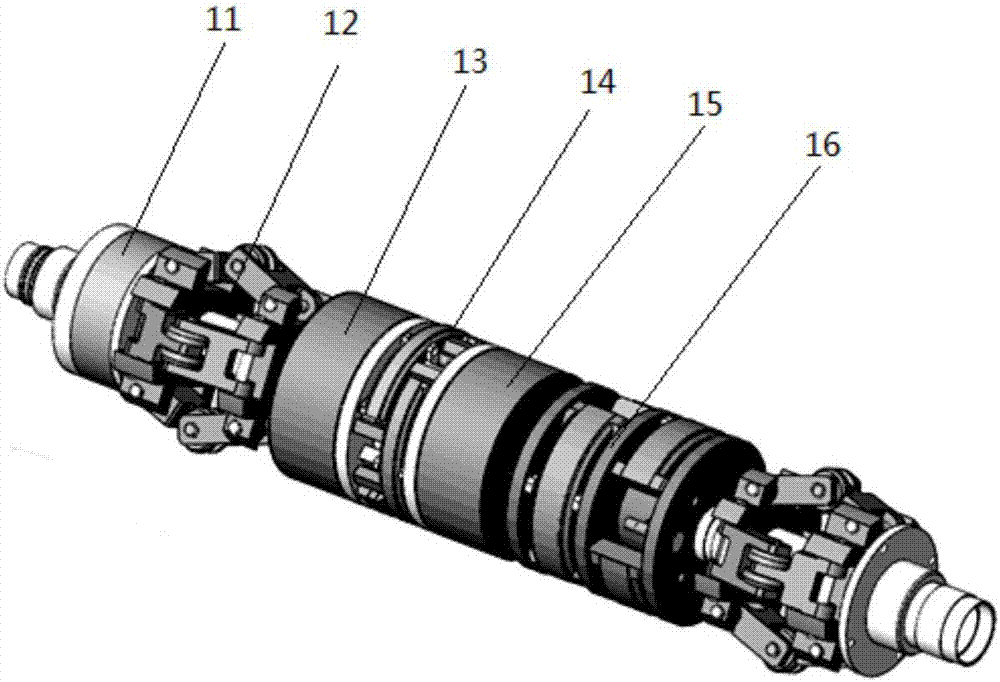

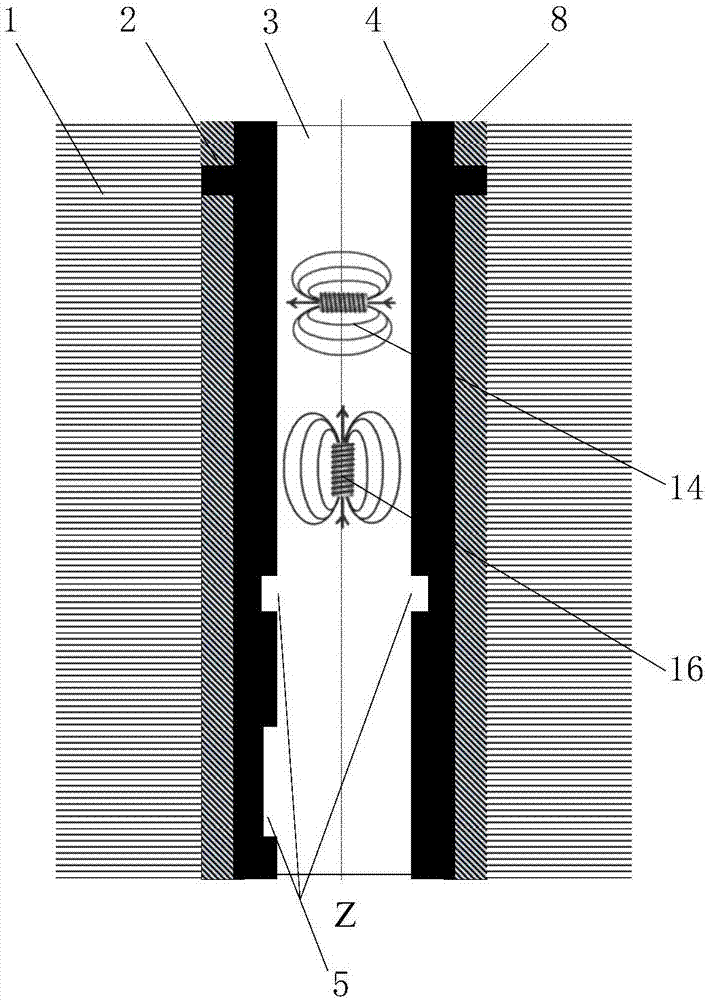

[0035] Embodiment 1: as figure 1 , image 3 , Figure 4 , Figure 5 As shown, the oil and gas storage well casing magnetic flux leakage test device includes a ground PC, a centralizer 12 and downhole instruments. The ground PC is connected to the downhole instrument through a cable, and the downhole instrument is connected to the centralizer, and is driven by the weight of the downhole instrument and the tension of the cable The centralizer and the downhole instrument move up and down in the casing; the downhole instrument includes an electrical box, a signal acquisition unit and a signal processing unit;

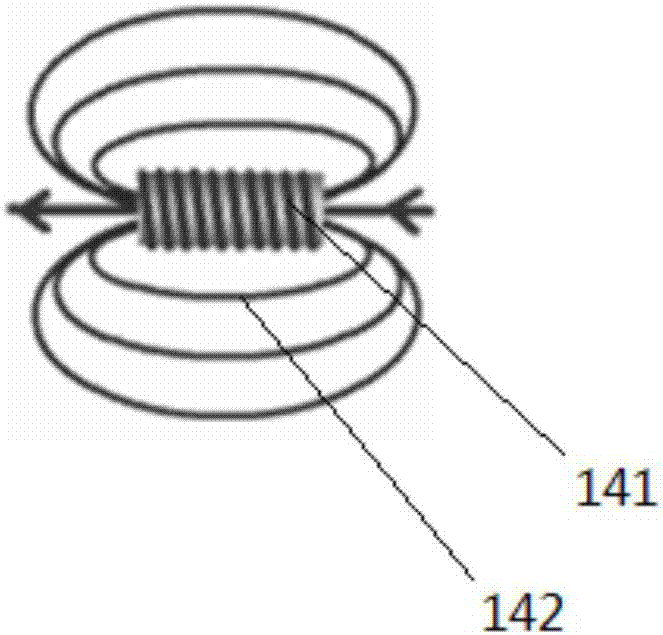

[0036] The signal acquisition unit includes a transverse magnetizer, a transverse detection unit, a wall thickness detection unit, a longitudinal magnetizer and a longitudinal detection unit connected in sequence; the transverse detection unit includes at least one transverse probe, and each group of transverse probes has multiple detection coils; the wall thickness detec...

Embodiment 2

[0038] Embodiment 2: Preferably, the transverse detection unit includes four sets of transverse probes arranged around the circumference of the casing, and each transverse magnet is wound with forty sets of coils.

Embodiment 3

[0039] Embodiment 3: Preferably, the longitudinal detection unit includes eighty circumferentially uniform longitudinal probes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com